A production process of high-strength anti-penetration foam concrete

A technology of foam concrete and production process, applied in the field of foam concrete, can solve the problems of easy absorption, limited application range, poor permeability resistance of foam cement, etc., and achieve the effects of increasing compressive strength, inhibiting penetration, and expanding the scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

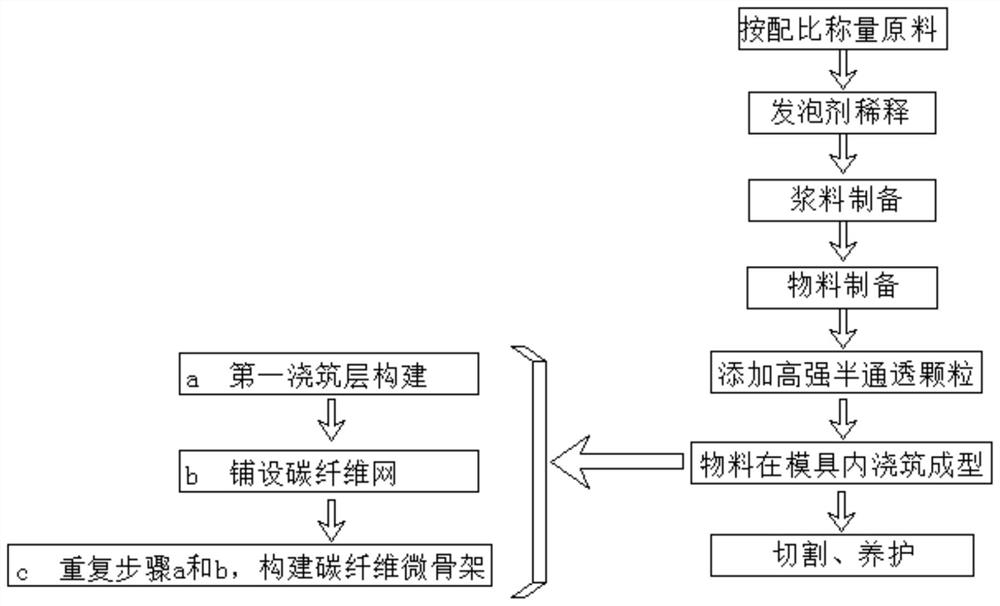

[0051] see figure 1 , a high-strength anti-permeability foam concrete production process, the foam concrete includes the following ingredients according to the mass ratio: 100 parts of water, 120 parts of ordinary Portland cement, 90 parts of coated wollastonite powder, and 35 parts of natural sandstone in the lower reaches of the river 15 parts of fly ash, 10 parts of fiber mixture, 20 parts of cationic surfactant, 6 parts of silane waterproofing agent, 3 parts of antifreeze and early strength agent, 3 parts of water reducing agent, 7 parts of protein foaming agent and foam stabilizer 4 parts of agent, the fiber mixture is made by mixing lignin fiber and tensile fiber according to 1:0.9, the compressive strength of this foam concrete can be regulated by adjusting the ratio of lignin fiber and tensile fiber, with the tensile strength As the fiber content increases, the compressive strength of the foamed concrete will gradually increase, and its production process includes the ...

Embodiment 2

[0060] see figure 1 , a high-strength anti-permeability foam concrete production process, the foam concrete includes the following ingredients according to the mass ratio: 200 parts of water, 180 parts of ordinary Portland cement, 120 parts of coated wollastonite powder, and 40 parts of natural sandstone in the lower reaches of the river 20 parts of fly ash, 15 parts of fiber mixture, 25 parts of cationic surfactant, 8 parts of silane waterproofing agent, 5 parts of antifreeze and early strength agent, 5 parts of water reducing agent, 10 parts of protein foaming agent and foam stabilizer 5 parts of agent, the fiber mixture is mixed by lignin fiber and tensile fiber according to 1:1.2, by adjusting the ratio of lignin fiber and tensile fiber, the compressive strength of this foam concrete can be regulated, with the tensile strength As the fiber content increases, the compressive strength of the foamed concrete will gradually increase, and its production process includes the fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com