A kind of anti-radiation organic glass containing tantalum and its preparation method

A plexiglass and radiation protection technology, applied in the field of radiation protection plexiglass preparation, can solve the problems of high lead toxicity, high temperature resistance and hardness, and achieve the effects of improving heat resistance, avoiding pollution, and having broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

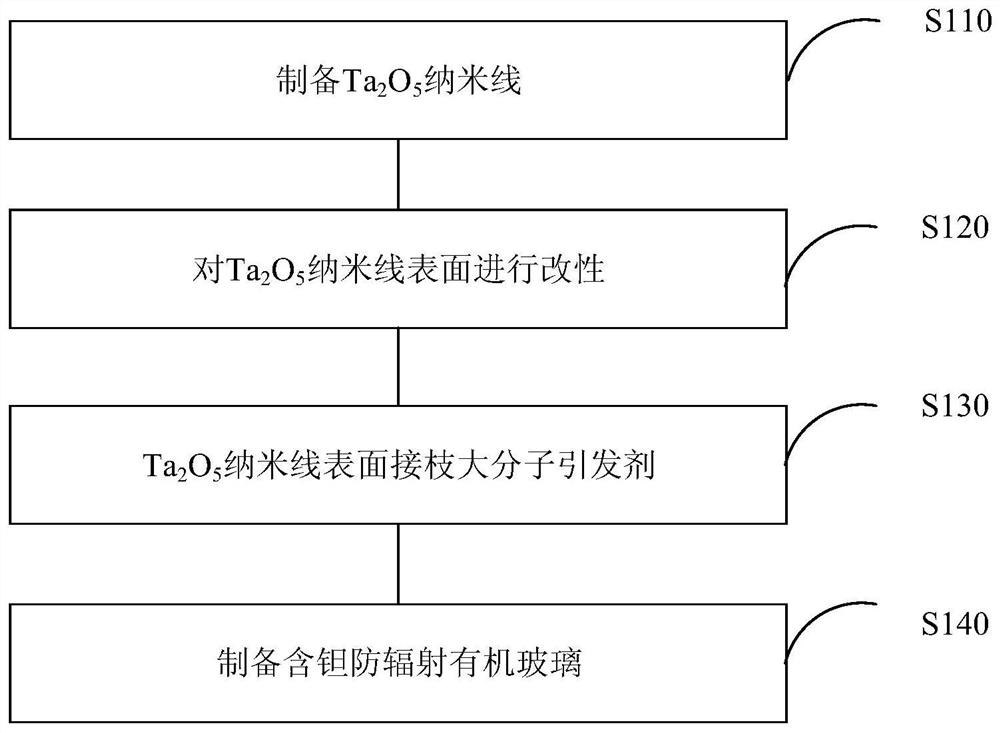

[0025] In the first aspect, the present invention provides a method for preparing anti-radiation organic glass containing tantalum, see figure 1 , the method at least includes the following steps S110 to S140:

[0026] Step S110 is to prepare Ta 2 o 5 Nanowire, the Ta 2 o 5 The powder particles are fully dissolved in the hydrofluoric acid solution, and then ammonia water is added to adjust the solvent to a predetermined alkaline pH value to obtain Ta(OH) 5 After the white precipitate, the precipitate was washed, and then dissolved in the mixed solution of hydrogen peroxide and ammonia water to obtain Ta 2 o 5 After the reaction precursor is transferred to the high pressure reactor for reaction, the resulting Ta 2 o 5 The nanowire precipitate was washed and freeze-dried to obtain Ta 2 o 5 nanowire powder. Ta 2 o 5 The nanostructure is easier to disperse in the matrix, in addition, due to the small size effect, the performance is more excellent.

[0027] Step S120 i...

Embodiment 1

[0032] Step S110, preparing Ta 2 o 5 Nanowire: Weigh 4g Ta 2 o 5 Add the powder particles into 40mL of hydrofluoric acid solution, put it in an oil bath at 110°C and stir for 2h to make Ta 2 o 5 The powder dissolves well. After dissolving, cool naturally to room temperature, add ammonia water to adjust the pH value of the solvent to 9.0, and obtain Ta(OH) 5 White precipitate. The precipitate was washed with deionized water and redissolved in a mixed solution of 120mL hydrogen peroxide and ammonia water (volume ratio 5:1) to obtain Ta 2 o 5 reaction precursors. For safety considerations, the precursor was heated at 60 °C for 1 h to promote the decomposition of hydrogen peroxide. Then the solution was transferred to an autoclave and reacted at 240 °C for 24 h. After the reaction finished, treat that the autoclave was down to room temperature, and the obtained Ta 2 o 5 The nanowire precipitate was repeatedly washed with deionized water and ethanol and centrifuged. Fi...

Embodiment 2

[0037] Step S110 and step S120 in embodiment 1 are all the same as embodiment 1, the difference is:

[0038] In step S130, Ta 2 o 5 When grafting macromolecular initiators on the surface of nanowires: add 2.5g of Ta 2 o 5 Nanowires.

[0039] In step S140, when preparing tantalum-containing anti-radiation organic glass: add 37.5 g of MMA to the spherical bottle after the reaction in the previous step, and finally obtain anti-radiation organic glass with excellent performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com