High-humidity flue gas particle sampling and measuring device and use method thereof

A measuring device and flue gas technology, applied in the direction of measuring device, sampling device, particle and sedimentation analysis, etc., can solve the problems of measurement and analysis of particle size characteristics of inapplicable particles, large error in sample collection, limited dehumidification capacity, etc., to achieve Improved dehumidification performance, easy operation, and strong practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, and its content is explanation of the present invention rather than limitation:

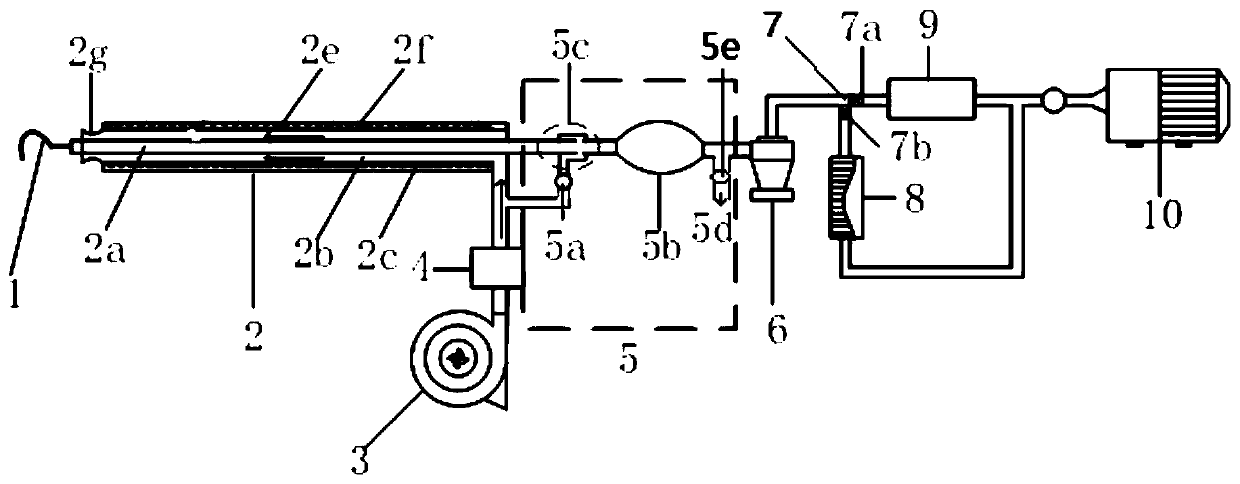

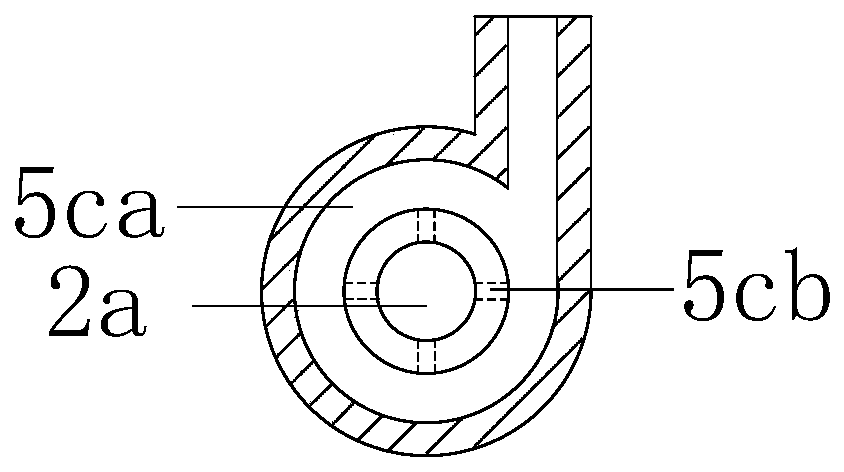

[0040] figure 1It is a schematic diagram of the overall structure of the present invention, which is suitable for particle sampling and measurement of high-humidity flue gas, mainly including: flue gas sampling gun head 1, high-humidity flue gas dehumidification device 2, blower 3, air dryer 4, flue gas dilution device 5. Cyclone separator 6, tee 7, first branch valve 7a, second branch valve 7b, particle sampling device 8, particle size measuring device 9, vacuum pump 10, and press figure 1 Connect sequentially.

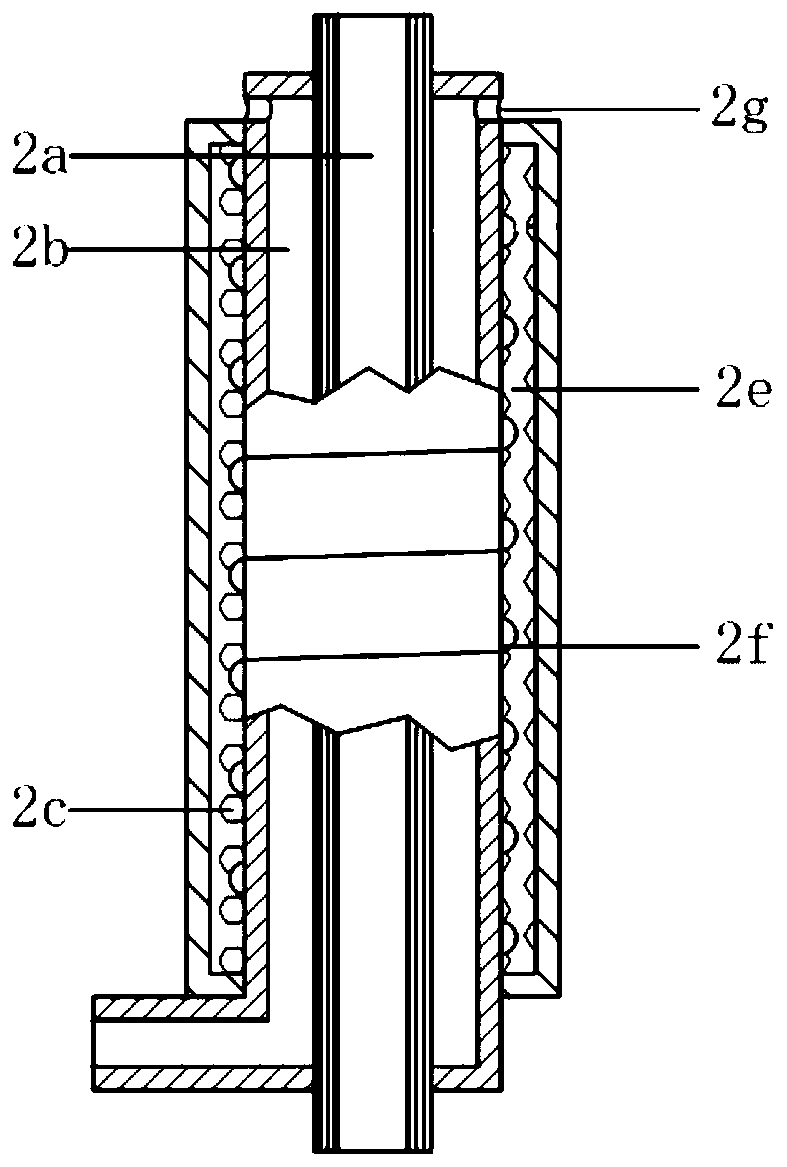

[0041] The high-humidity flue gas dehumidification device such as figure 2 As shown, the whole is a casing structure, which is divided into the first chamber in the flue gas pipe 2a, the second chamber formed by the flue gas pipe 2a and the dry air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com