Tm3+ doping-based fluoride glass microsphere laser

A glass microsphere, fluoride technology, applied in the direction of active medium materials, etc., can solve the problems of difficult temperature control, surface cracks, easy deterioration of surface quality, etc., and achieve the effect of miniaturization, simple structure, and integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] With reference to the above-mentioned technical principles, the Tm doping has been completed in the embodiments of the present invention. 3+ The realization of the ZBYA fluoride glass microsphere 2μm laser, the specific process is as follows:

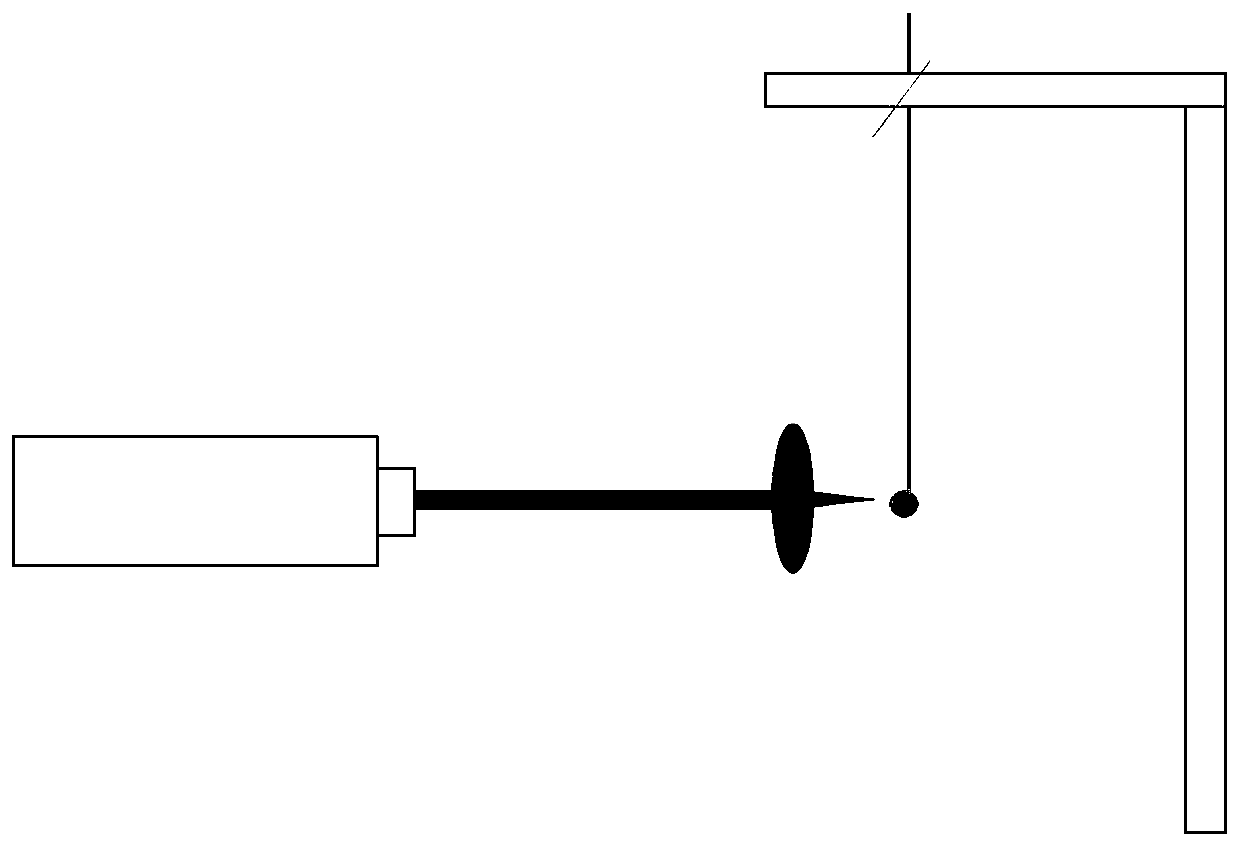

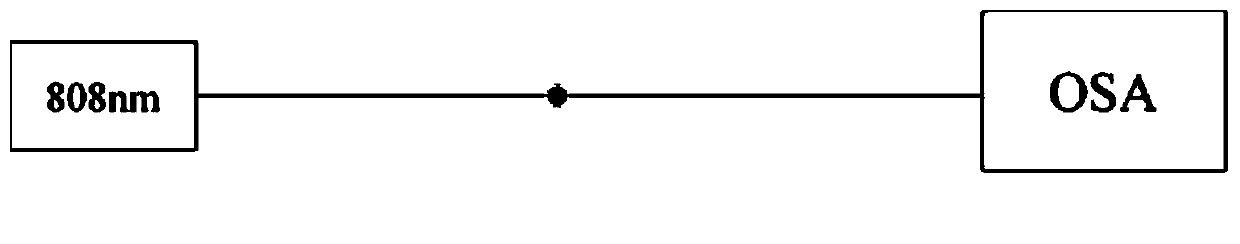

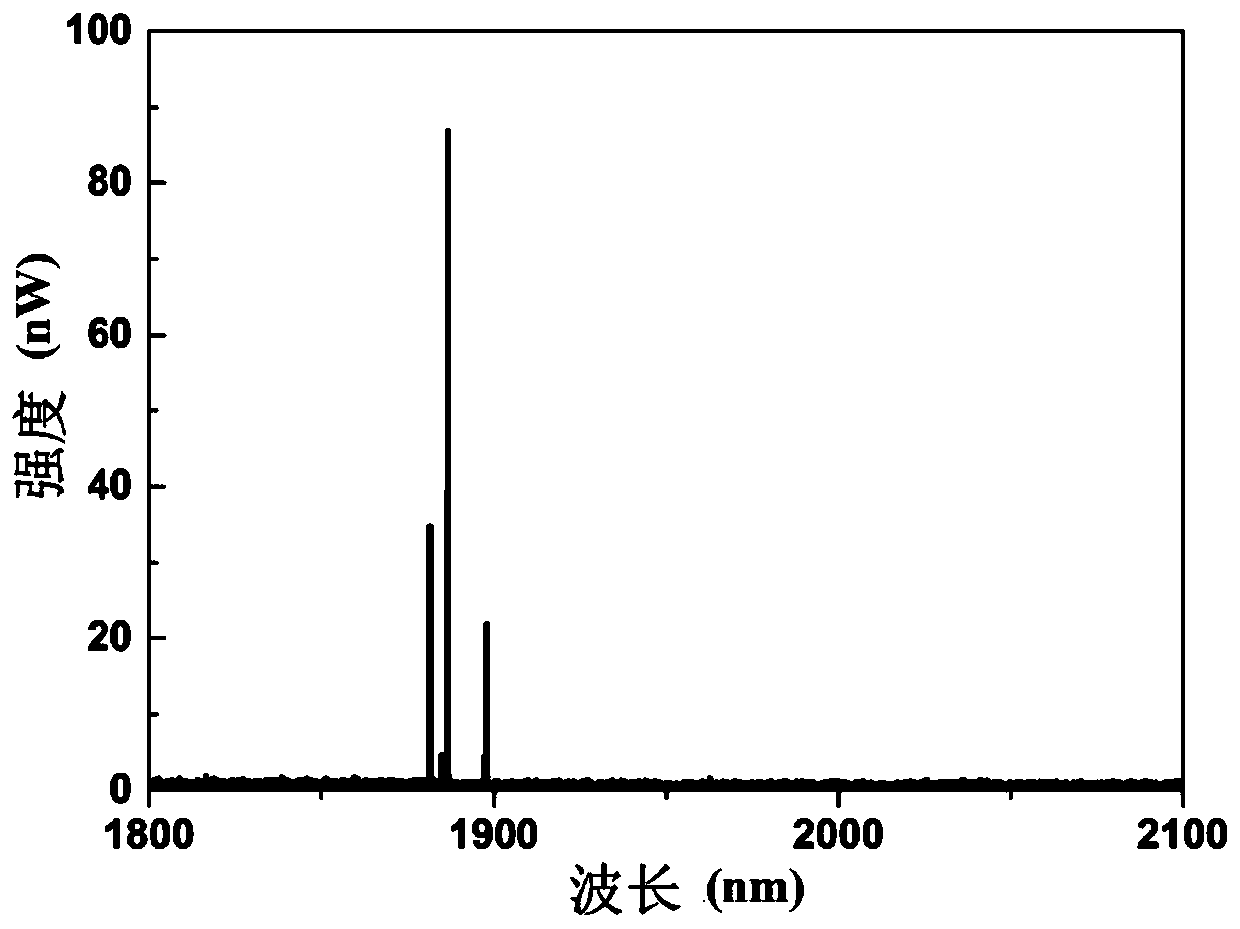

[0027] The prepared microspheres are coupled with the micro-nano optical fiber, and one end of the optical fiber is connected to the pumping source, and the pumping source used is a conductor laser with a center wavelength of 808nm and a half. The other end is connected to a spectrometer to observe the laser output. The structure of the whole laser is simple, and the pump source excites Tm-doped 3+ ZBYA fluoride glass microspheres can get 2μm laser. The excitation process mainly uses the evanescent field of the tapered fiber to couple the pump laser into the microsphere, and finally outputs the laser through the WGM mode. When the 808nm pump source is set to 5.6mW, by optimizing the coupling position of the microsphere and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com