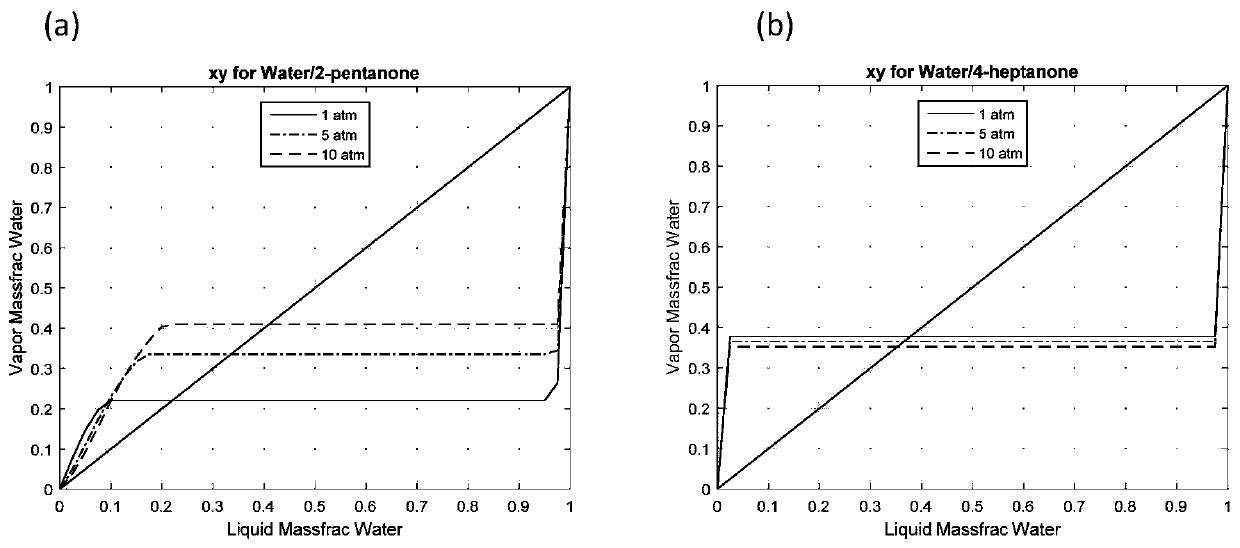

Heterogeneous azeotropic distillation method for separating 2-pentanone, 4-heptanone, water and carbon dioxide mixture

A carbon dioxide and azeotropic distillation technology, which is applied in the field of distillation process system, can solve the problems of difficult to achieve high-purity separation of components, low degree of equipment integration, and limited to binary systems, so as to save equipment investment costs and Installation space, reduction of equipment investment cost and effect of low installation space and equipment investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

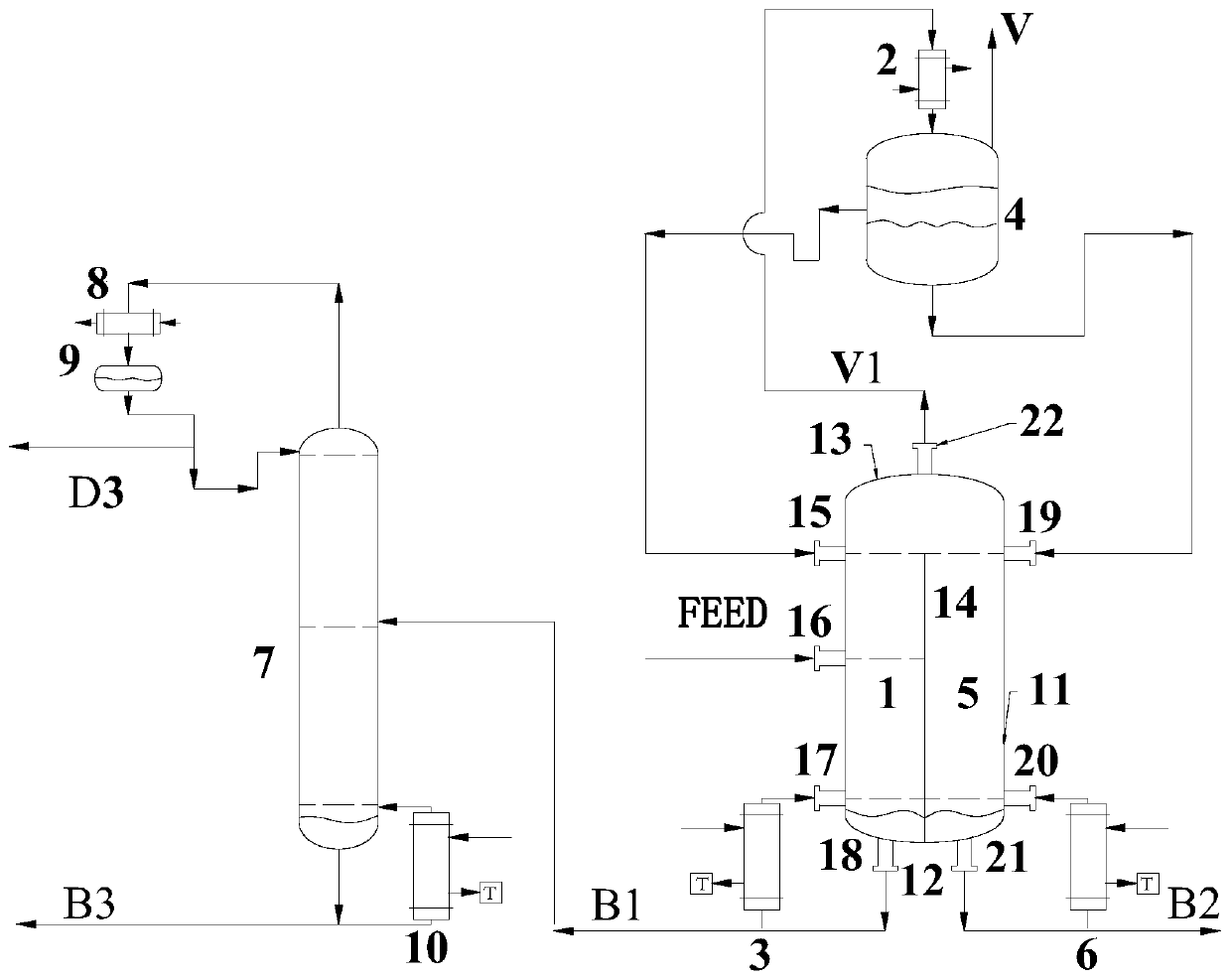

Embodiment 1

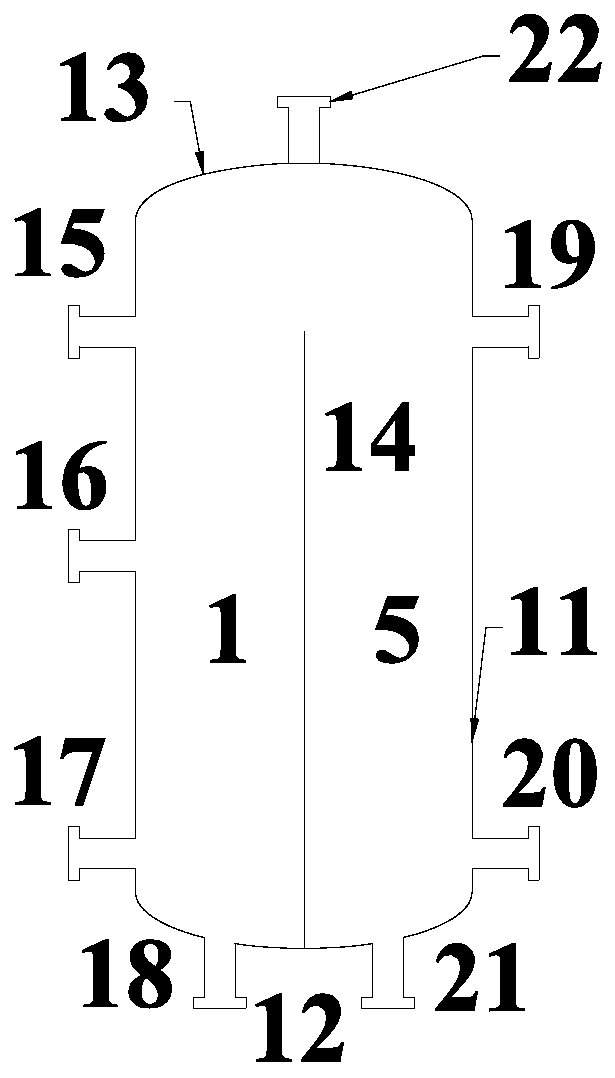

[0045] A kind of partition tower, it comprises housing 11, lower sealing head 12, upper sealing head 13, there is rectangular dividing plate 14 between housing 11 along the axial direction of housing 11, and housing 11 is divided into partition wall left side 1 and On the right side of the next door 5, the bottom of the rectangular partition 14 goes directly to the lower head 12, and the top of the rectangular partition 14 goes directly to the upper head 13, or there is a part of space between the upper side and the upper head 13, and there is a ketone-rich phase inlet on the upper part of the left side of the next door 1 15. There is an inlet 16 for raw materials to be separated in the middle, an inlet 17 for a ketone-rich phase reboiler at the bottom, a mixed ketone outlet 18 at the bottom of the lower head 12 on the left side 1 of the next door, and an inlet 19 for a water-rich phase at the upper part on the right side 5 of the next door. There is a water-rich phase reboiler...

Embodiment 2

[0076] A kind of partition tower, it comprises housing 11, lower sealing head 12, upper sealing head 13, there is rectangular dividing plate 14 between housing 11 along the axial direction of housing 11, and housing 11 is divided into partition wall left side 1 and On the right side of the next door 5, the bottom of the rectangular partition 14 goes directly to the lower head 12, and the top of the rectangular partition 14 goes directly to the upper head 13, or there is a part of space between the upper side and the upper head 13, and there is a ketone-rich phase inlet on the upper part of the left side of the next door 1 15. There is a ketone-rich phase reboiler inlet 17 in the lower part, a mixed ketone outlet 18 at the bottom of the lower head 12 on the left side 1 of the next door, and a water-rich phase inlet 19 in the upper part on the right side 5 of the next door, and a water-rich phase reboiler in the lower part The device inlet 20 has a water phase outlet 21 at the bo...

Embodiment 3

[0107] A kind of partition tower, it comprises housing 11, lower sealing head 12, upper sealing head 13, there is rectangular dividing plate 14 between housing 11 along the axial direction of housing 11, and housing 11 is divided into partition wall left side 1 and On the right side of the next door 5, the bottom of the rectangular partition 14 goes directly to the lower head 12, and the top of the rectangular partition 14 goes directly to the upper head 13, or there is a part of space between the upper side and the upper head 13, and there is a ketone-rich phase inlet on the upper part of the left side of the next door 1 15. There is an inlet 16 for raw materials to be separated in the middle, an inlet 17 for a ketone-rich phase reboiler at the bottom, a mixed ketone outlet 18 at the bottom of the lower head 12 on the left side 1 of the next door, and an inlet 19 for a water-rich phase at the upper part on the right side 5 of the next door. There is a water-rich phase reboiler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com