Food starch processing grinding device

A starch processing and grinding device technology, applied in grain processing, etc., can solve the problems of cumbersome maintenance and disassembly, complex structure, and poor promotion, and achieve the effects of improving efficiency, reducing losses, and reducing impacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

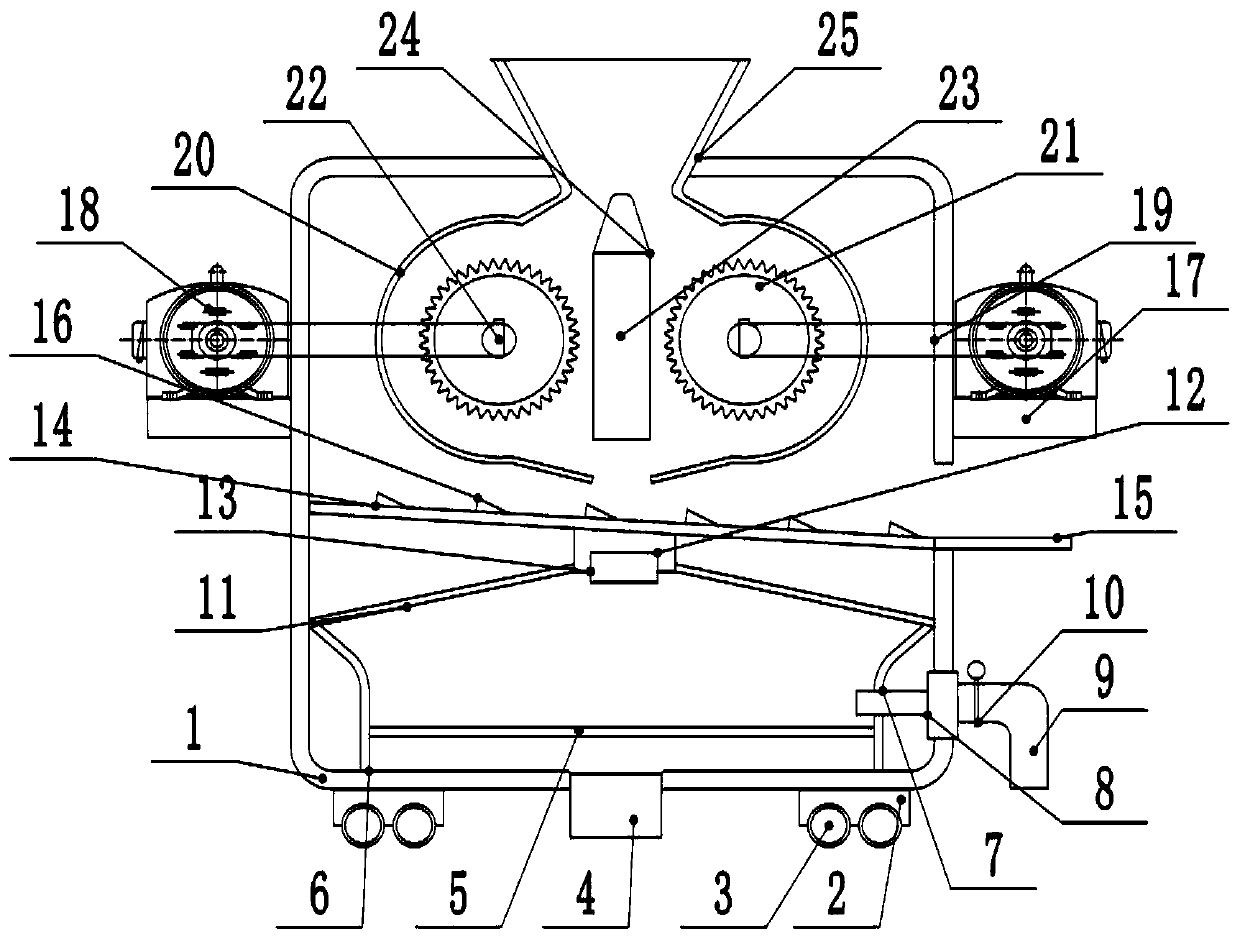

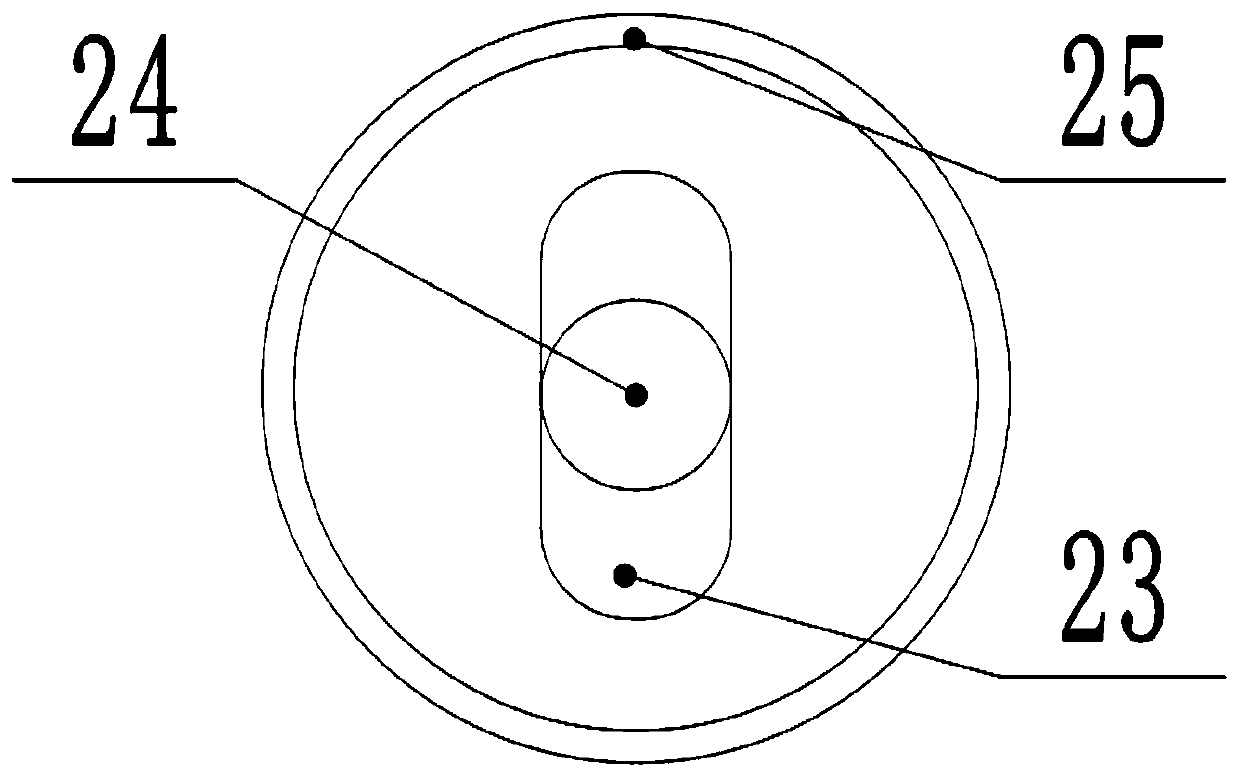

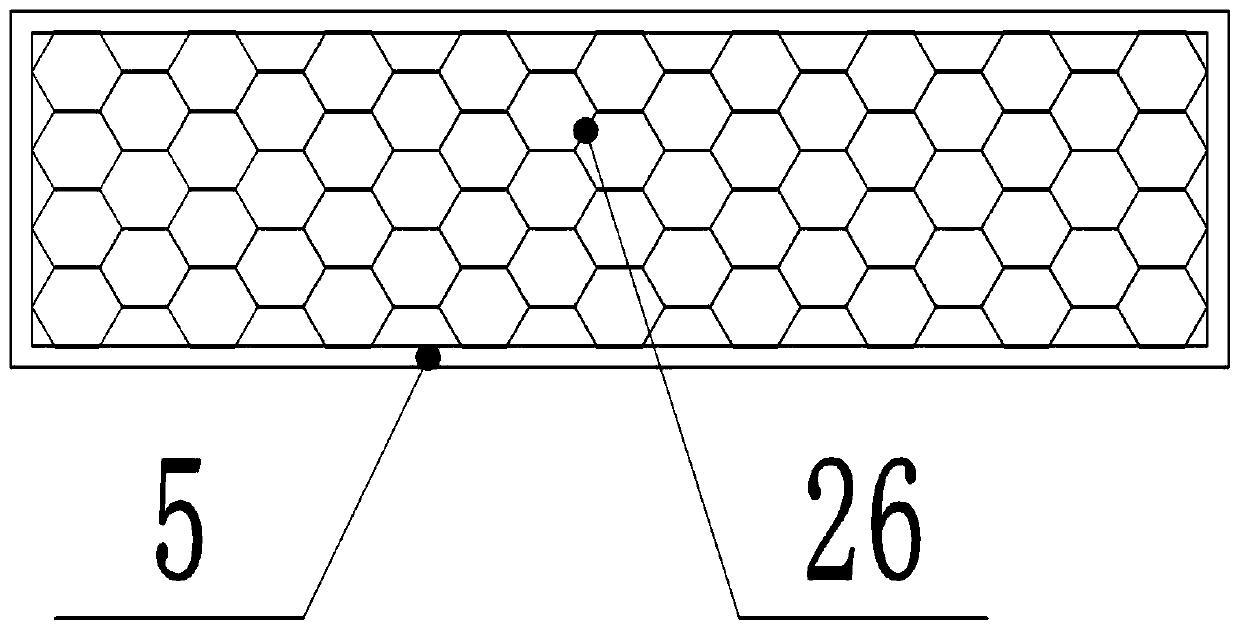

[0020] see figure 1 , a food starch processing and grinding device, comprising: an equipment shell 1, a wheel bracket 2, a wheel 3, a discharge port 4, a partition plate 5 and a feeding funnel 25, the equipment shell 1 is designed in stainless steel, and has good Corrosion-resistant and easy to clean, the bottom of the equipment housing 1 is provided with a wheel bracket 2, and the middle part of the wheel bracket 2 is rotatably mounted with a wheel 3, and the outer ring of the wheel 3 is provided with a rubber pad, and the rubber has good cushioning and shock absorption ability, can reduce the vibration of the equipment and the noise generated during operation. The upper middle part of the equipment casing 1 is provided with a feeding funnel 25. The inner wall of the feeding funnel 25 has been polished and smoothed to avoid feeding jams. The wheel bracket 2 The outer rings on both sides are provided with a motor fixing plate 17, the upper end of the motor fixing plate 17 is f...

Embodiment 2

[0023] Compared with Embodiment 1, Embodiment 2 differs only in that the belt 19 is a V-shaped belt with stable transmission, low noise, cushioning and vibration absorption, fast and convenient maintenance, and is suitable for use in food processing equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com