Colorless clear flexible polyurethane having high dielectric constant and self-repairing method thereof

A high dielectric constant and polyurethane technology, applied in the field of high dielectric constant flexible polyurethane and its self-repair, can solve the problems of transparent polymers losing high transparency, unable to meet the touch screen conditions, and polymer materials that have not been reported. , to achieve the effect of reversible self-healing, remarkable repairing effect, and outstanding bending ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041](1) At room temperature, mix 100g of hydroxyl-terminated polyalkylene carbonate diol (molecular weight: 2000), 67g of isophorone diisocyanate, 31g of 2,2'-dithiodiethanol, and 0.02g of dilauric acid Dibutyltin and 500 g of dichloromethane were mixed; then the temperature was raised to 55° C., and the temperature was kept for 1 hour to obtain an isocyanate-terminated oligomer solution, which was designated as solution B.

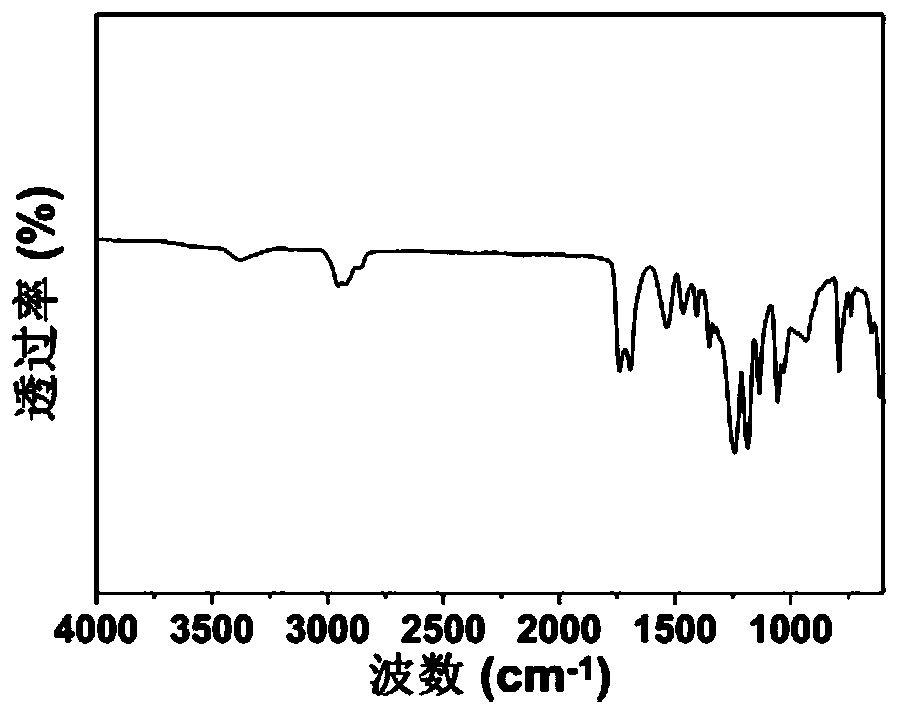

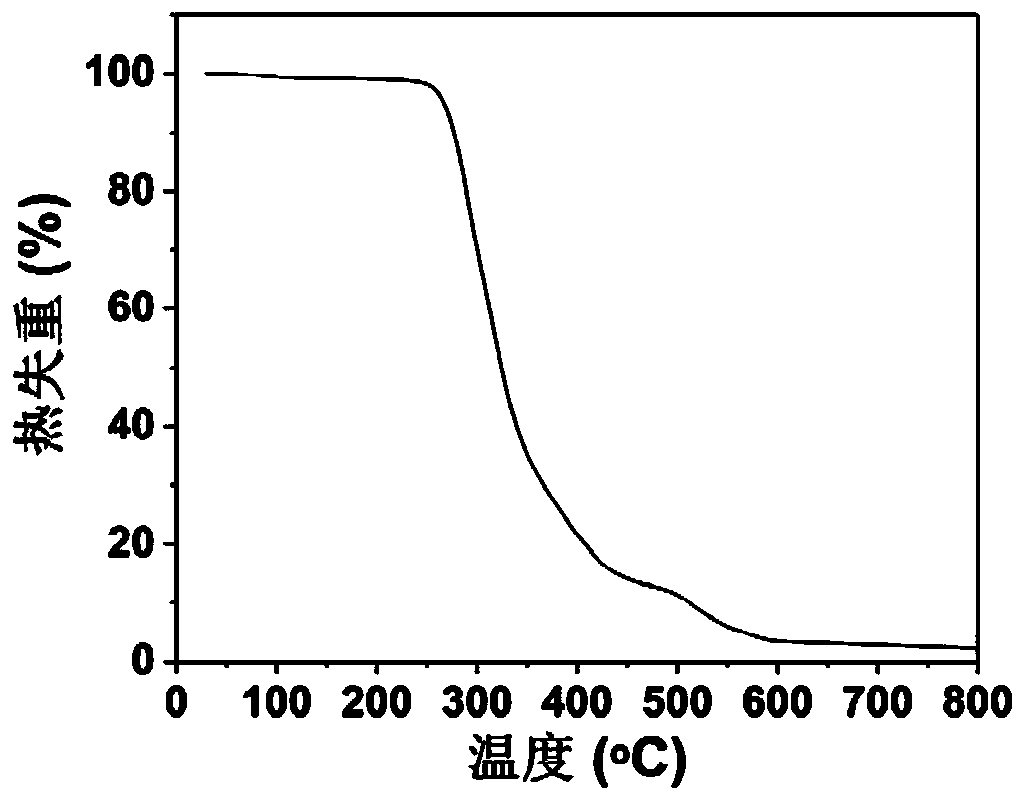

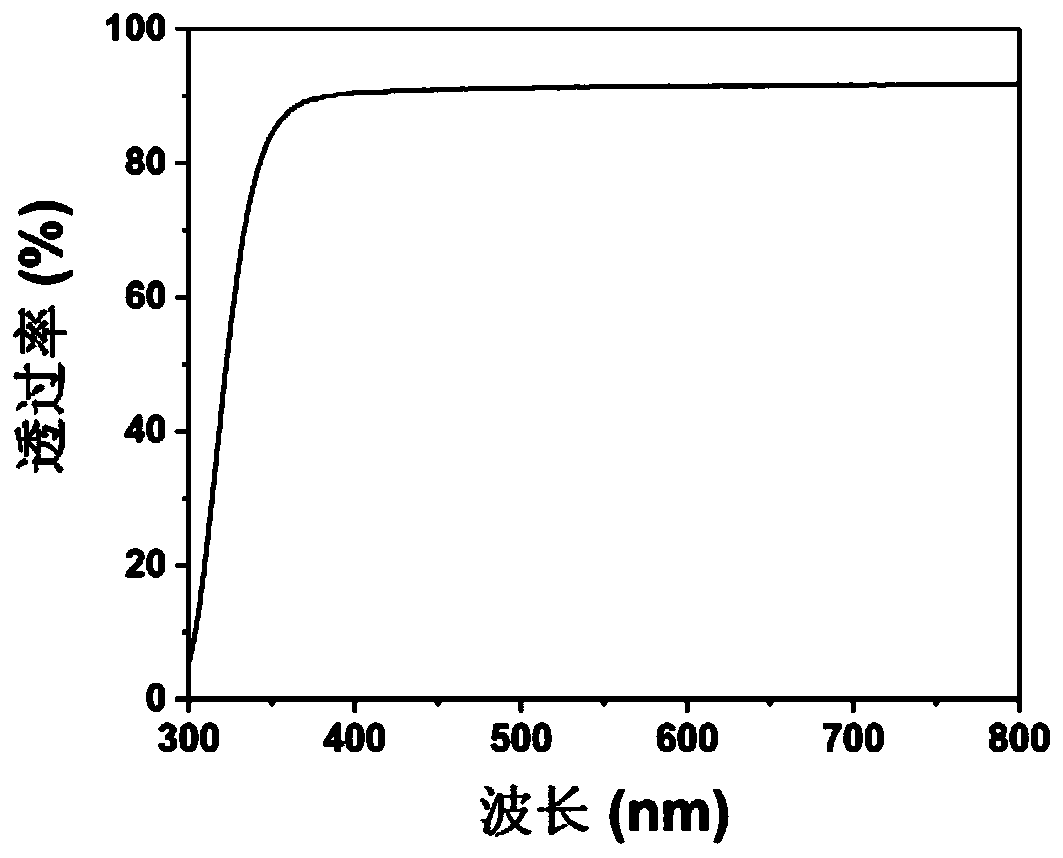

[0042] (2) At room temperature, add 4g of trimethylolpropane, 20g of lithium bistrifluoromethanesulfonimide and 20g of 1-ethyl-3-methylimidazole bistrifluoromethanesulfonimide salt to solution B, Then react at a temperature of 60°C for 1h; then pour it into a mold, dry, and form a film to obtain a colorless and transparent flexible polyurethane film with high dielectric constant. Its infrared spectrum, thermal weight loss curve, ultraviolet-visible spectrum, fold Digital photographs before and after and after blower heating, tensile stress-strain curves...

Embodiment 2

[0063] (1) At room temperature, 100g of hydroxyl-terminated polyalkylene carbonate diol (molecular weight: 2000), 50g of hexamethylene diisocyanate, 23g of 2,2'-dithiodiethanol, 0.01g of Dibutyltin dilaurate, 500g of dichloromethane and 500g of chloroform were mixed; then the temperature was raised to 60°C and then kept for 0.5h to obtain an isocyanate-terminated oligomer solution, which was designated as solution D.

[0064] (2) At room temperature, add 9g of trimethylolpropane, 10g of lithium bistrifluoromethanesulfonimide and 40g of 1-ethyl-3-methylimidazole bistrifluoromethanesulfonyl to solution D imide salt, and then react at a temperature of 60° C. for 1 hour; then pour it into a mold and dry it to obtain a colorless and transparent flexible polyurethane film with high dielectric constant.

[0065] (3) The self-healing method of the colorless, transparent, highly flexible and high-dielectric polyurethane composite material is: self-healing method after fracture. Fully ...

Embodiment 3

[0067] (1) At room temperature, 100g of hydroxyl-terminated polyalkylene carbonate diol (molecular weight: 2000), 105g of cyclohexylmethane diisocyanate, 35g of 2,2'-dithiodiethanol, and 0.03g of dithiol Dibutyltin laurate, 300g of dichloromethane and 300g of 1,2 dichloroethane were mixed; then the temperature was raised to 60°C and then kept for 1 hour to obtain an isocyanate-terminated oligomer solution, which was designated as solution E.

[0068](2) At room temperature, add 11g of trimethylolpropane, 40g of lithium bistrifluoromethanesulfonimide and 30g of 1-ethyl-3-methylimidazole bistrifluoromethanesulfonyl to solution E imide salt, and then react at a temperature of 40° C. for 1 hour; then pour it into a mold and dry it to obtain a colorless and transparent flexible polyurethane film with high dielectric constant.

[0069] (3) The self-healing method of the colorless, transparent, highly flexible and high-dielectric polyurethane composite material is: self-healing metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com