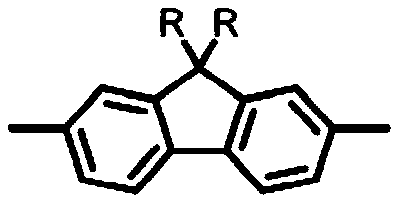

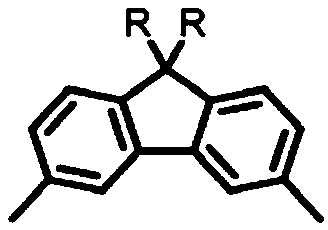

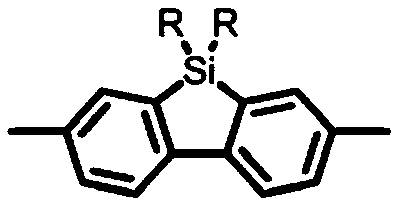

Trianiline thiofluorene unit-based blue light conjugated polymer, and preparation method and application thereof

A conjugated polymer, triphenylamine technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to achieve the effect of improving device efficiency, good solubility, and balanced injection and transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Preparation of 4-octyl-N,N-diphenylamine

[0053] Under argon protection, in a 250mL two-necked flask, diphenylamine (7.90g, 46.66mmol), p-octylbromobenzene (12.56g, 46.66mmol) and sodium tert-butoxide (25.22g, 233.31mmol) were dissolved in 100mL of toluene , then added tri-tert-butylphosphine (472.03mg, 2.33mmol) and palladium acetate (209.52mg, 933.24umol), heated to 110°C, and reacted for 16 hours. Add aqueous solution to quench the reaction, rotary evaporate most of the solvent, the reaction mixture is poured into water, and extracted with dichloromethane, washed 5 times, the organic phase is separated, dried, filtered, and the crude product is analyzed by column chromatography after spin-drying the solvent. Purification, yield: 78%. 1 H NMR, 13 CNMR, MS and elemental analysis results show that the obtained compound is the target product, and its chemical reaction equation is as follows:

[0054]

Embodiment 2

[0056] Preparation of 4-bromo-N-(4-octylbenzene)-N-aniline

[0057]Add 4-octyltriphenylamine (35.7g, 0.1mol) and 200mL dimethylformamide into a 500mL three-neck flask, stir until dissolved, dissolve NBS (17.8g, 0.1mol) in 150mL DMF, and cool to about 0°C in an ice bath , slowly add NBS solution dropwise, react in the dark, after the dropwise addition, let the temperature rise automatically, and react for 6 hours. The reaction solution was added dropwise to water to precipitate, and the crude product was extracted with dichloromethane. Dry over anhydrous magnesium sulfate, filter, and spin dry the solvent. The pure substance was separated by column chromatography to obtain a light yellow viscous solid, yield: 88%. 1 H NMR, 13 CNMR, MS and elemental analysis results show that the obtained compound is the target product, and its chemical reaction equation is as follows:

[0058]

Embodiment 3

[0060] Preparation of Octyltriphenylamine Borate (M1)

[0061] Under an argon atmosphere, 4-bromo-N-(4-octylbenzene)-N-aniline (12.76 g, 29.24 mmol) was dissolved in 180 mL of refined THF, and 1.6 mol L of -1 20mL of n-butyllithium, reacted for 2 hours, then quickly added 20mL of 2-isopropoxy-4,4,5,5-tetramethyl-1,3,2-dioxaborane, at -78℃ The reaction was continued for 1 hour, and the temperature was slowly raised to room temperature for 24 hours. The reaction mixture was poured into water, extracted with ethyl acetate, and the organic layer was washed with brine and dried over anhydrous magnesium sulfate. After the solution was concentrated, a light yellow viscous crude product was obtained, which was purified by silica gel column chromatography. The product was placed in the refrigerator for a long time to obtain a white solid with a yield of 70%. 1 H NMR, 13 C NMR and GC-MASS tests showed that it was the target product.

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com