A graphene-based anti-icing/deicing integrated wrinkled film and preparation method thereof

A graphene film and graphene-based technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of anti-icing and deicing difficulties, delay the time of heterogeneous nucleation, slow down heat exchange, The effect of a high free energy barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

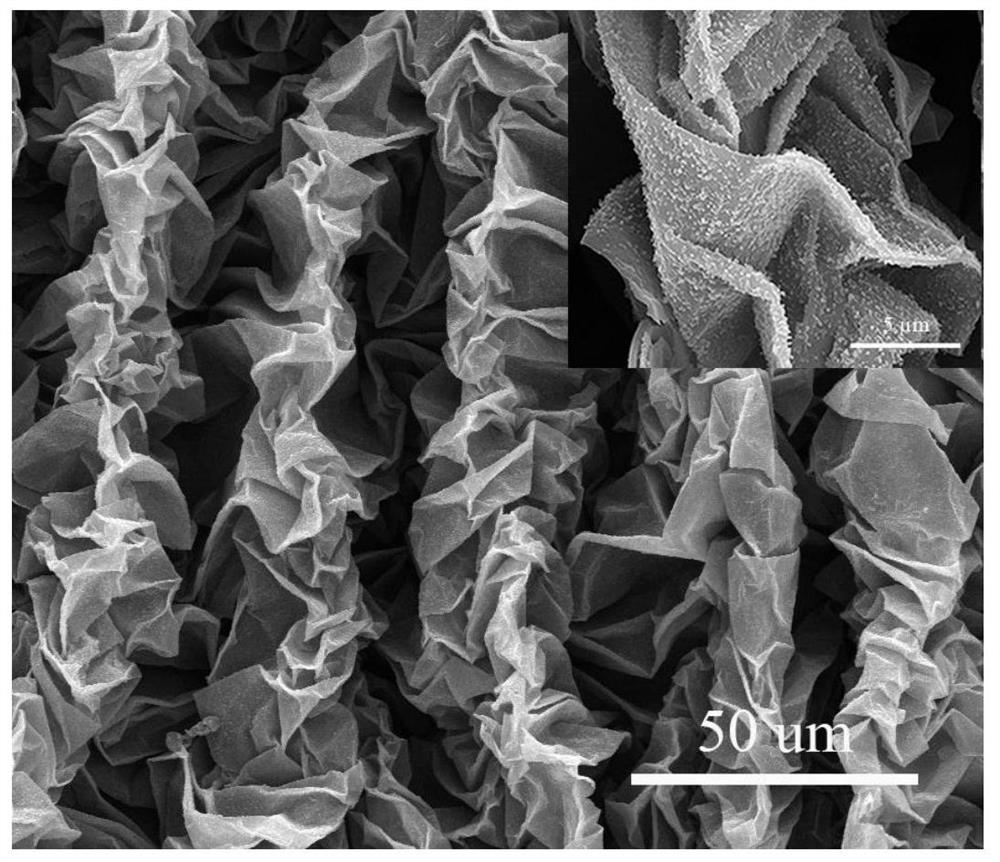

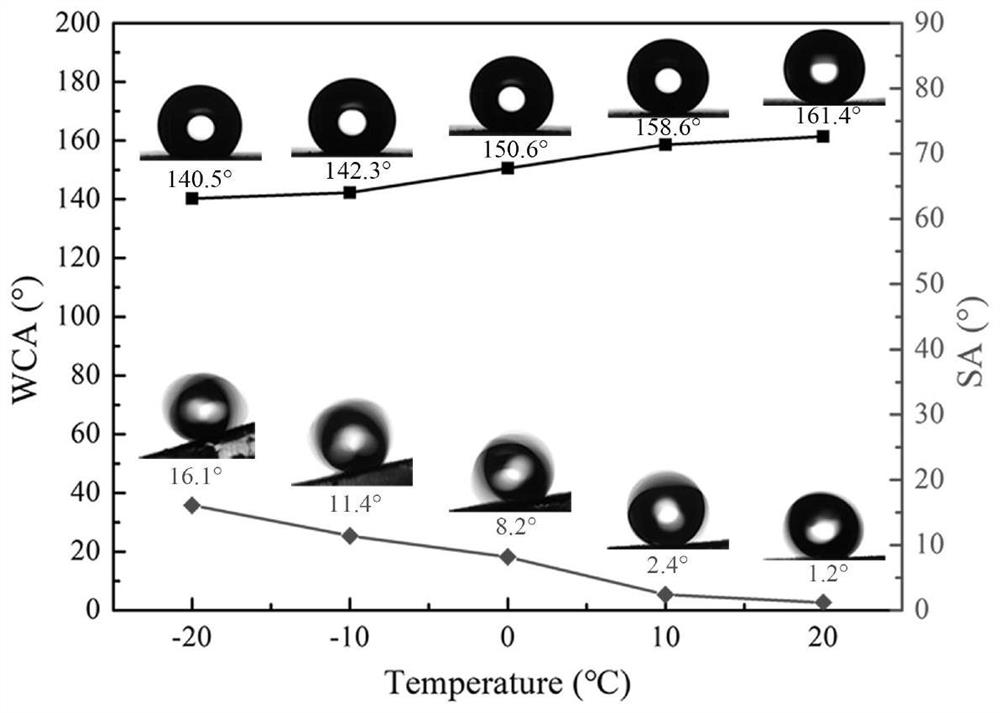

[0030] Embodiment 1: a kind of graphene-based anti-icing / deicing integrated wrinkled film (FSGF) is realized through the following steps in the present embodiment:

[0031] Step 1, transfer the rGO (reduced graphene oxide) film to the biaxially stretched acrylic base film with a pre-strain of 400% by dry method;

[0032] Step 2, then release the base film along one uniaxial direction to make it shrink back, and then release the base film in another uniaxial direction to make it shrink back to its original size to obtain rGO wrinkled film;

[0033] Step 3: Add 30 mg of cetyltrimethylammonium bromide (CTAB) into the ammonia-water mixture, mix well, then put into step 2 to obtain rGO wrinkled film, stir magnetically for 6 hours under heating in a water bath at 40°C, and then gradually Add 1 mL of tetraethyl orthosilicate drop by drop, keep stirring for 12 hours after the dropwise addition, then take it out and dry it at 50°C;

[0034] Step 4, then drop 10 μL of 1% (mass) FDTS (1...

Embodiment 2

[0047] Embodiment 2: a kind of graphene-based anti-icing / de-icing integrated wrinkled film (FSGF) is realized through the following steps in the present embodiment:

[0048] Step 1, transfer the rGO (reduced graphene oxide) film to the biaxially stretched acrylic base film with a pre-strain of 400% by dry method;

[0049] Step 2, then release the base film along one uniaxial direction to make it shrink back, and then release the base film in another uniaxial direction to make it shrink back to its original size to obtain rGO wrinkled film;

[0050] Step 3: Add 50 mg of cetyltrimethylammonium bromide (CTAB) into the ammonia-water mixture, mix well, then put into step 2 to obtain rGO wrinkled film, stir magnetically for 6 hours under heating in a water bath at 45°C, and then gradually Add 2 mL of tetraethyl orthosilicate drop by drop, keep stirring for 12 hours after the dropwise addition, then take it out and dry it at 50°C;

[0051] Step 4, then drop 10 μL of 1% (mass) FDTS (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com