Laundry detergent composition containing amphoteric polymer

A technology of laundry detergent and amphoteric polymer, applied in detergent composition, organic detergent composition, detergent compounding agent, etc., can solve the problems of insufficient removal and ineffective redeposition of fabric grease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] monomer synthesis

[0060] 2-Carboxy-N,N-dimethyl-N-(2'-(methacryloyloxy)ethyl)ethylimmonium internal salt (CBMA) monomer was synthesized according to the method described by Zhang et al. (Superlow Fouling Sulfobetaine and Carboxybetaine Polymers on Glass Slides, Langmuir, Vol. 22, No. 24, 2006, 10073). γ-propiolactone in dry acetone was added dropwise to a solution of 2-(N,N′-dimethylamino)ethyl methacrylate in dry acetone, and the reaction was stirred at 15 °C for 24 h. The solvent was then evaporated to obtain a viscous liquid of CBMA monomer.

[0061] polymer synthesis

[0062] Free-radical polymerization of CBMA monomers in aqueous media was carried out using the method described by Lee et al. (1994), Vol. 35, No. 10, 2210-2217). Polymerization was performed using potassium persulfate as an initiator and stirring at 60 to 70° C. for 8 hours in an inert atmosphere. The molecular weight of the CBMA homopolymer is in the range of 10000 to 100000 Da.

[0063] Cop...

Embodiment 2

[0066] pretreatment test

[0067] Polyester samples were treated with polymer solutions containing different concentrations of the CBMA homopolymer of Example 1 and a control sample without any polymer. Samples were allowed to dry, then stained with artificial sebum (0.2 mL) and aged for 24 hours. The sample was then washed in a Tergotometer at 110 rpm in 24° fH (French Hardness) water (without additives or surfactants) at ambient conditions and then dried.

[0068] The SRI (Stain Removal Index) of the dried scoured fabric samples was determined. by using Artix ScannerF1 with software: Silverfast Ai Studio, Lasersoft Imaging Measure the reflectance (value at 460 nm, excluding and including UV) of the fabric sample measured at R460 to determine the SRI value.

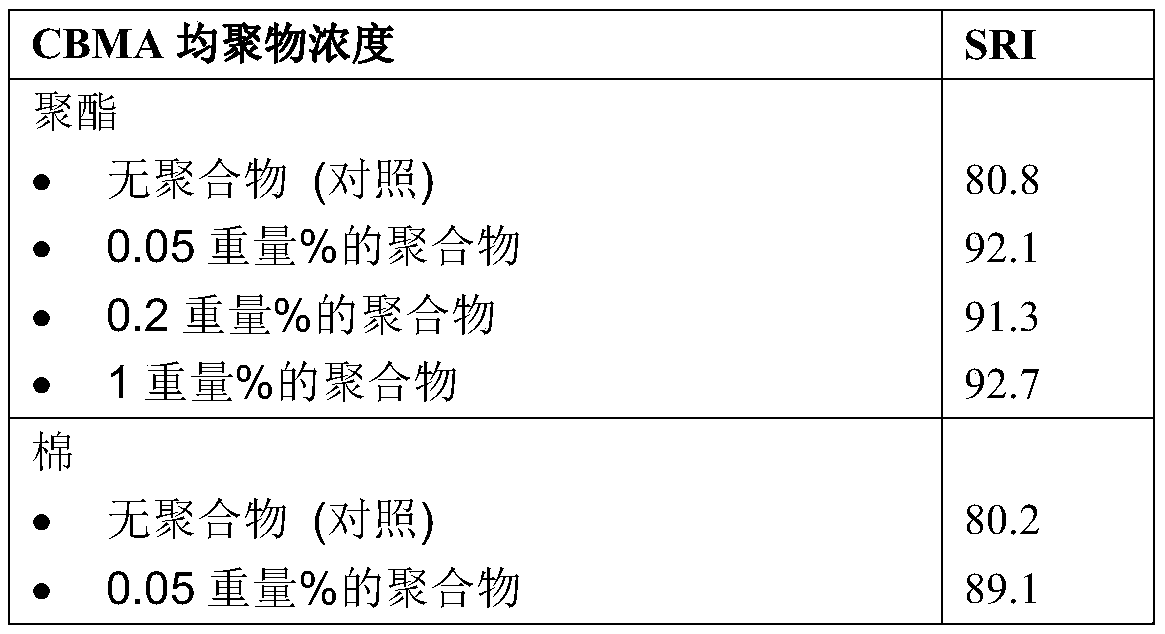

[0069] The results of these measurements are shown in Table 1.

[0070] Table 1

[0071] Concentration of CBMA Homopolymer

Embodiment 3

[0073] Example 1 was repeated, except this time the polyester and cotton samples were first stained with model sebum and then aged for 24 hours. These stained fabric samples were run in water (24°fH) at ambient temperature at 110 rpm in a Tergotometer. cleaning in the presence of is a commercial detergent composition from Unilever.

[0074] The results are listed in Table 2.

[0075] Table 2

[0076]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com