Early-strength type polycarboxylate superplasticizer and preparation method and application thereof

A technology of polycarboxylic acid and water reducer, which is applied in the field of concrete admixtures, can solve the problems of poor strength, accelerated cement hydration, and high cost, and achieve excellent fluidity, early strength, enhanced repellency, and improved The effect of early strength performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

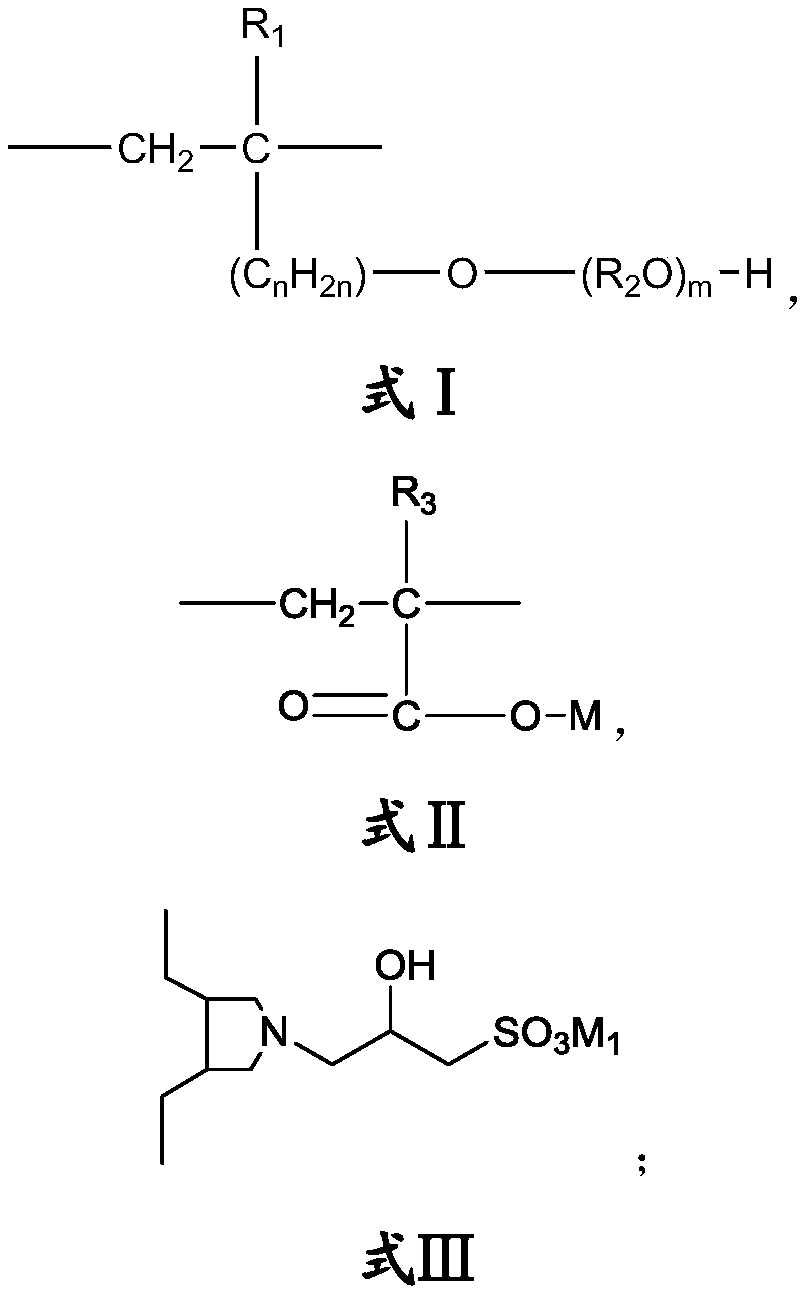

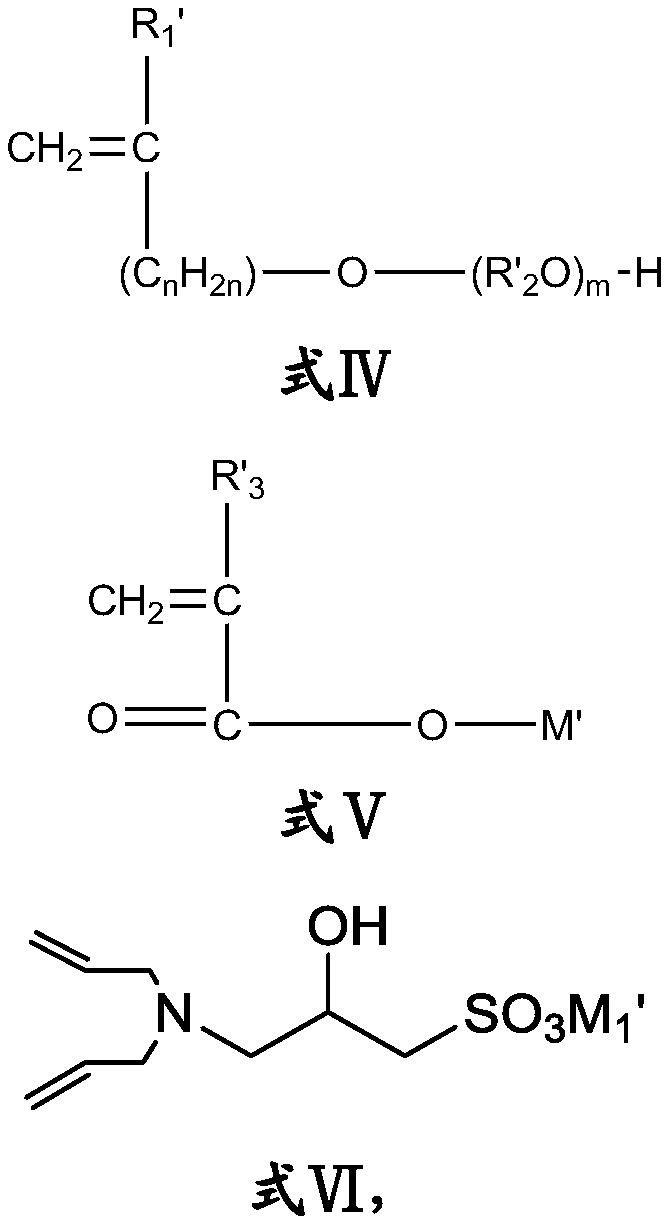

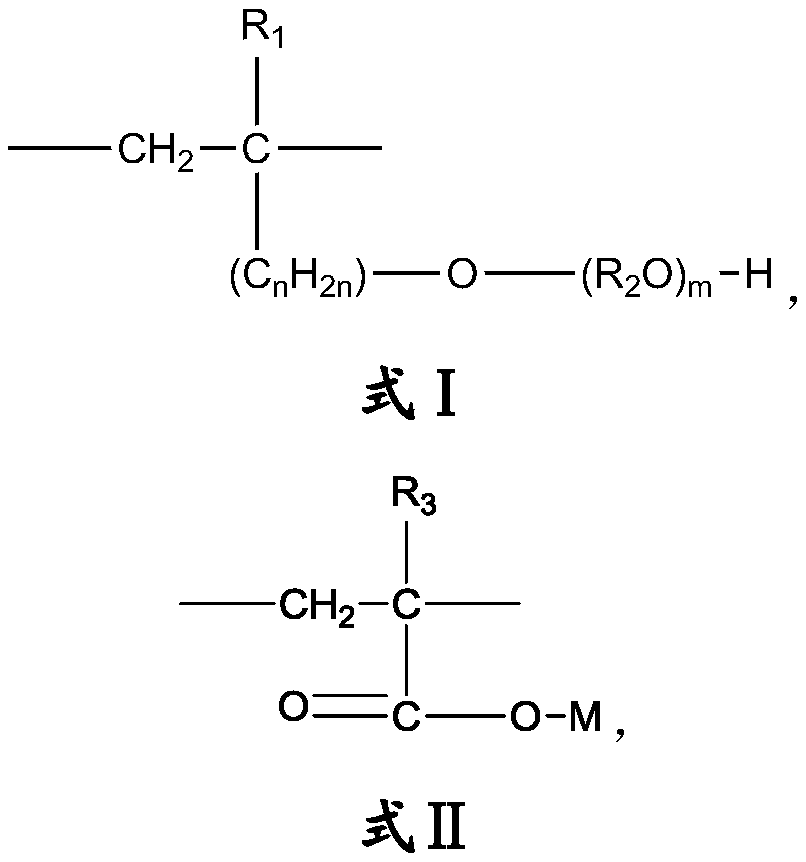

Method used

Image

Examples

Embodiment 1

[0048] At 20°C, 87g of methallyl polyoxyethylene polyether (molecular weight: 2400) was dissolved in 60g of water in a kettle, 0.8g of mercaptoacetic acid and 0.3g of L-ascorbic acid were added, and then 6g of acrylic acid, Mixture of 7g 3-(diallylamino)-2-hydroxypropyl sodium sulfonate, 1.5g hydrogen peroxide (30% by mass aqueous solution), and 40g water, the time for adding is 2h, and aging for 1h after the addition is completed , and cooled to room temperature to obtain the early-strength superplasticizer product S1.

[0049] Product S1 is characterized by infrared spectroscopy, and the infrared spectrum is 3440.22cm -1 It is the stretching vibration of O-H; 2871.21cm -1 and 2873.44cm -1 The strong absorption peak is -CH 2 The stretching vibration of - and -CH 3 Bending vibration; 1731.25cm -1 The strong absorption peak is the vibration peak of C=O, 1185.15cm -1 for-SO 3 Stretching vibration of Na, 1105.45cm -1 and 1259.68cm -1 The strong absorption peak at -C-O-C-...

Embodiment 2

[0052] Under the condition of 10°C, 90g of methallyl polyoxyethylene polyether (molecular weight: 2000) was dissolved in 60g of water in a kettle, and 0.1g of mercaptoacetic acid and 1.0g of L-ascorbic acid were added, followed by the dropwise addition of 2g of acrylic acid, A mixture of 8g 3-(diallylamino)-2-hydroxypropyl sodium sulfonate, 3.3g hydrogen peroxide (30% by mass aqueous solution), and 40g water, the time for the dropwise addition is 2h, after the dropwise addition is completed, mature for 2h , and cooled to room temperature to obtain the early-strength water reducer product S2.

[0053] Product S2 is characterized by infrared spectroscopy, and the infrared spectrum is 3441.86cm -1 It is the stretching vibration of O-H; 2871.88cm -1 and 2873.64cm -1 The strong absorption peak is -CH 2 The stretching vibration of - and -CH 3 Bending vibration; 1731.75cm -1 The strong absorption peak is the vibration peak of C=O, 1185.60cm -1 for-SO 3 Stretching vibration of ...

Embodiment 3

[0056] At 40°C, put 82g of methallyl polyoxyethylene polyether (molecular weight: 5000) in a kettle and dissolve it in 60g of water, add 1.0g of mercaptoacetic acid, 0.02g of L-ascorbic acid, and then start to drop 9g of sodium acrylate , the mixed solution of 9g 3-(diallylamino)-2-hydroxypropyl sulfonate, 0.33g hydrogen peroxide (30% by mass aqueous solution), 40g water, the time for adding is 2h, and ripening after the addition is completed After 1 hour, cool to room temperature to obtain the early-strength water reducer product S3.

[0057] The product S3 is characterized by infrared spectroscopy, and the infrared spectrum is 3441.16cm -1 It is the stretching vibration of O-H; 2871.28cm -1 and 2873.34cm -1 The strong absorption peak is -CH 2 The stretching vibration of - and -CH 3 Bending vibration; 1556.25cm -1 The strong absorption peak is the vibration peak of C=O, 1186.45cm -1 for-SO 3 Stretching vibration of Na, 1104.85cm -1 and 1258.54cm -1 The strong absorpt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com