High-strength heat-resisting aluminum alloy and preparation method thereof

An aluminum alloy material and heat-resistant technology, which is applied in the field of heat-resistant aluminum alloy materials, can solve the problems of limited interface bonding strength, low material plasticity, and low plasticity, so as to facilitate coordinated deformation, improve high-temperature mechanical properties, and excellent plasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

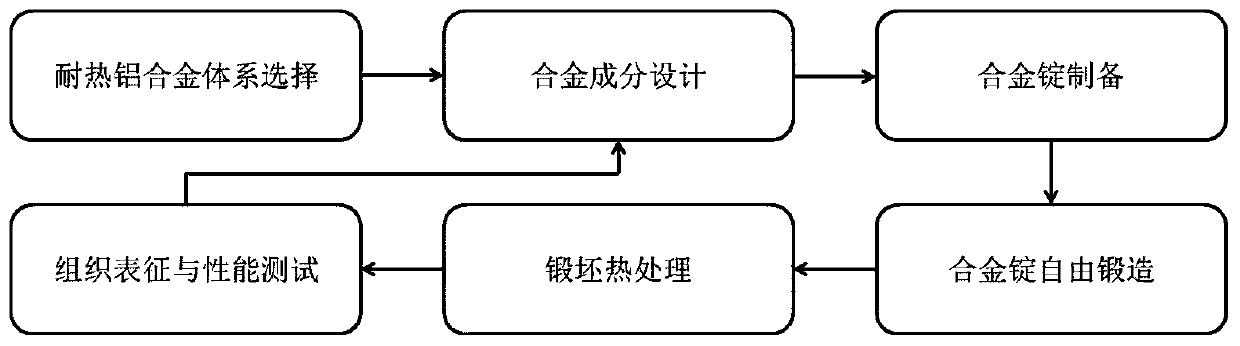

[0025] (1) Alloy composition selection

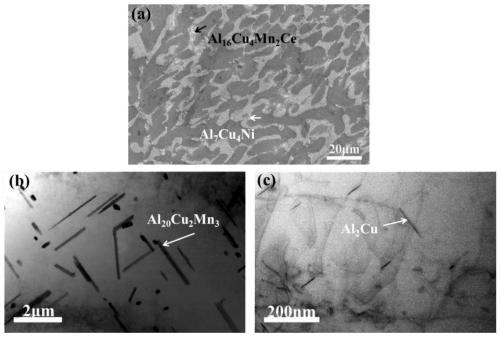

[0026] Select the heat-resistant aluminum alloy system, according to the solidification phase diagram, Al a1 Cu b1 mn c1 Ce d1 Quaternary alloy aluminum-rich end (81.0≤a 1 ≤94.0, 5.0≤b 1 ≤14.0, 0.5≤c 1 ≤2.0, 0.5≤d 1 ≤3.0) Precipitation of Al 16 Cu 4 mn 2 Ce, Al 20 Cu 2 mn 3 、Al 2 Cu phase, Al a2 Cu b2 Ni c2 Ternary alloy aluminum-rich end (78.0≤a 2 2 ≤12.0, 02 ≤10.0) Al precipitation 7 Cu 4 Ni phase, thereby adjusting the alloy composition Al 86.1 Cu 8.3 mn 1.0 Ce 2.4 Ni 2.0 Zr 0.2 ;

[0027] (2) Selection of raw materials

[0028] The purity of each metal component that the present invention prepares alloy ingot for selection is as table 1, and alloy composition is Al 86.1 Cu 8.3 mn 1.0 Ce 2.4 Ni 2.0 Zr 0.2 (weight percent);

[0029]Table 1 Purity (%) of metal components selected for the preparation of alloy ingots

[0030] alloy element

Al

Cu

mn

Zr

Ni

Al-10%Ce

pur...

Embodiment 2

[0044] (1) Alloy composition selection

[0045] Select the heat-resistant aluminum alloy system, according to the solidification phase diagram, Al a1 Cu b1 mn c1 Ce d1 Quaternary alloy aluminum-rich end (81.0≤a 1 ≤94.0, 5.0≤b 1 ≤14.0, 0.5≤c 1 ≤2.0, 0.5≤d 1 ≤3.0) Precipitation of Al 16 Cu 4 mn 2 Ce, Al 20 Cu 2 mn 3 、Al 2 Cu phase, Al a2 Cu b2 Ni c2 Ternary alloy aluminum-rich end (78.0≤a 2 2 ≤12.0, 02 ≤10.0) Al precipitation 7 Cu 4 Ni phase, adjust the alloy composition Al 86.4 Cu 8.4 mn 1.2 Ce 2.3 Ni 1.5 Zr 0.2 ;

[0046] (2) Selection of raw materials

[0047] The purity of each metal component that the present invention prepares alloy ingot for selection is as table 1, and alloy composition is Al 86.4 Cu 8.4 mn 1.2 Ce 2.3 Ni 1.5 Zr 0.2 (weight percent);

[0048] Table 1 Purity (%) of metal components selected for the preparation of alloy ingots

[0049] alloy element

Al

Cu

mn

Zr

Ni

Al-10%Ce

purity / %

...

Embodiment 3

[0063] (1) Alloy composition selection

[0064] Select the heat-resistant aluminum alloy system, according to the solidification phase diagram, Al a1 Cu b1 mn c1 Ce d1 Quaternary alloy aluminum-rich end (81.0≤a 1 ≤94.0, 5.0≤b 1 ≤14.0, 0.5≤c 1 ≤2.0, 0.5≤d 1 ≤3.0) Precipitation of Al 16 Cu 4 mn 2 Ce, Al 20 Cu 2 mn 3 、Al 2 Cu phase, Al a2 Cu b2 Ni c2 Ternary alloy aluminum-rich end (78.0≤a 2 2 ≤12.0, 02 ≤10.0) Al precipitation 7 Cu 4 Ni phase, adjust the alloy composition Al 83.75 Cu 9.0 mn 2.0 Ce 2.5 Ni 2.5 Zr 0.25 ;

[0065] (2) Selection of raw materials

[0066] The purity of each metal component that the present invention prepares alloy ingot for selection is as table 1, and alloy composition is Al 83.75 Cu 9.0 mn 2.0 Ce 2.5 Ni 2.5 Zr 0.25 (weight percent);

[0067] Table 1 Purity (%) of metal components selected for the preparation of alloy ingots

[0068] alloy element

Al

Cu

mn

Zr

Ni

Al-10%Ce

purity / % ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com