Biological cleaning retention belt for sponge city municipal road

A technology for municipal roads and biological purification, applied in the direction of roads, roads, inorganic chemistry, etc., can solve the problems that suspended particles cannot pass through, and the treatment effect of heavy metals is poor, so as to improve the exchangeability of cations, strong physical and chemical adsorption capacity, and regeneration simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

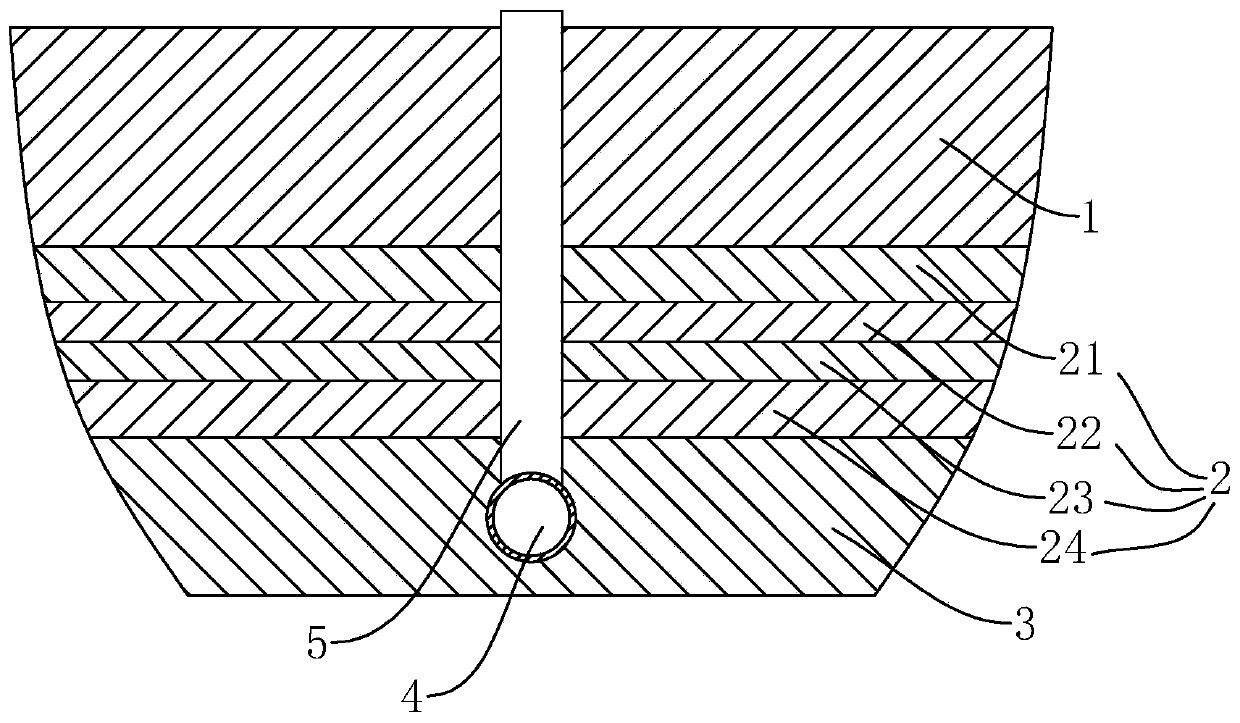

[0047] A kind of bio-purification retention zone for municipal roads in sponge cities, such as figure 1As shown, it includes planting soil layer, filter layer and drainage layer from top to bottom. The planting soil layer is composed of soil suitable for plant growth and is used for planting green plants; the filter layer includes fine sand layer A, adsorption layer A, adsorption layer B, fine sand layer B, fine sand layer A and fine sand layer from top to bottom Layer B is composed of fine sand with a particle size of 0.125-0.25mm; the drainage layer is composed of pebbles or gravel with a particle size of 10-30mm. Perforated drainage pipes for rainwater inflow are laid on the drainage layer, and overflow pipes are connected at intervals along the length of the perforated drainage pipes, and the overflow pipes pass through the filter layer and the planting soil layer and are higher than the surface of the planting soil layer.

[0048] After the rainwater flows to the plantin...

Embodiment 2

[0050] The adsorption layer A in Example 1 includes the following components by weight: 80 parts of modified attapulgite and 30 parts of modified montmorillonite.

[0051] The preparation process of modified attapulgite is as follows:

[0052] In the first step, according to the mass ratio of solid to liquid of 1:50, attapulgite and water are mixed and stirred evenly, and then a dispersant accounting for 2% of the mass of attapulgite is added, and the dispersant is composed of sodium polyacrylate and sodium polyacrylate with a mass ratio of 1:1. It is compounded with sodium hexametaphosphate, then stirred at 600r / min for 2 hours, left to stand, and after stable stratification occurs, take the upper suspension, and then heat to 100°C until the water is completely evaporated, crushed, and passed through a 200-mesh sieve to obtain purification After the attapulgite;

[0053] The second step is to mix the purified attapulgite with the acid solution according to the solid-to-liqui...

Embodiment 3

[0059] The adsorption layer A in Example 1 includes the following components by weight: 100 parts of modified attapulgite and 50 parts of modified montmorillonite.

[0060] The preparation process of modified attapulgite is as follows:

[0061] In the first step, according to the mass ratio of solid to liquid of 1:50, attapulgite and water are mixed and stirred evenly, and then a dispersant accounting for 3% of the mass of attapulgite is added, and the dispersant is composed of sodium polyacrylate and sodium polyacrylate with a mass ratio of 1:1. It is compounded with sodium hexametaphosphate, then stirred at 800r / min for 3 hours, left to stand, and after stable stratification occurs, take the upper layer suspension, and then heat to 105°C until the water is completely evaporated, crushed, and passed through a 200-mesh sieve to obtain purification After the attapulgite;

[0062] The second step is to mix the purified attapulgite with the acid solution according to the solid-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com