Alkali-free liquid setting accelerator and preparation method thereof

A technology of quick-setting agent and liquid, which is applied in the field of alkali-free liquid quick-setting agent and its preparation, which can solve problems such as strength decline, and achieve the effect of preventing later strength decline, no loss of strength, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

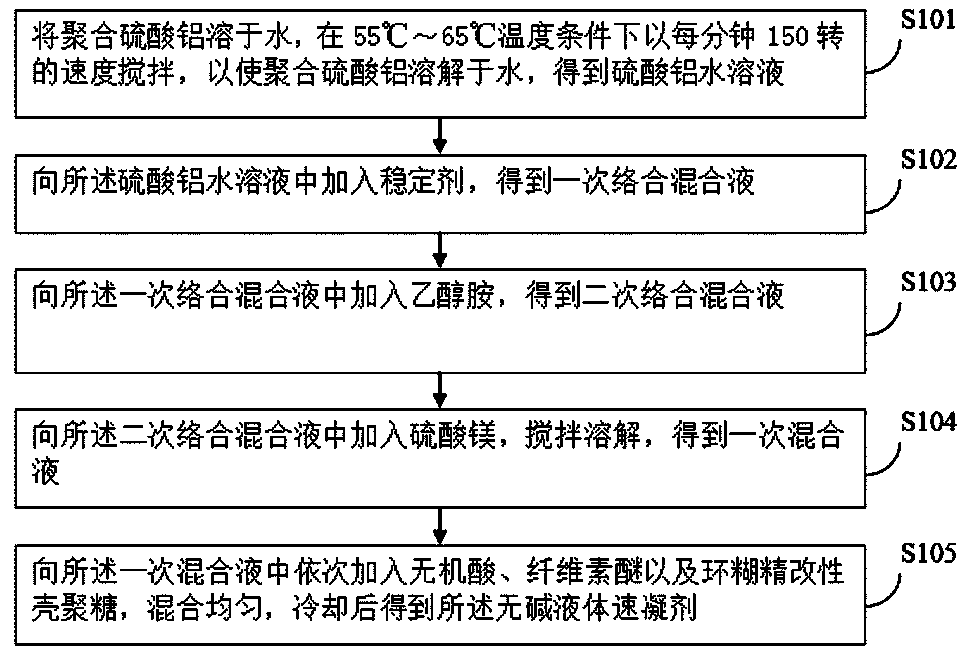

[0035] see figure 1 , is a schematic flow diagram of the preparation method of the non-alkali liquid quick-setting agent provided by the embodiment of the present invention, and the preparation method includes the following steps:

[0036] Step S101, dissolving polyaluminum sulfate in water, and stirring at a speed of 150 revolutions per minute at a temperature of 55° C. to 65° C., so that polyaluminum sulfate is dissolved in water to obtain an aqueous solution of aluminum sulfate;

[0037] Step S102, adding a stabilizer to the aluminum sulfate aqueous solution to obtain a primary complexed mixed solution;

[0038] Step S103, adding a stabilizer to the aluminum sulfate aqueous solution to obtain a primary complexed mixed solution;

[0039] Step S104, adding magnesium sulfate to the secondary complexation mixed solution, stirring and dissolving to obtain the primary mixed solution;

[0040] Step S105, adding mineral acid, cellulose ether, and cyclodextrin-modified chitosan to...

Embodiment 2

[0042] Step S101, dissolving polyaluminum sulfate in water, and stirring at a speed of 150 revolutions per minute at a temperature of 55° C. to 65° C., so that polyaluminum sulfate is dissolved in water to obtain an aqueous solution of aluminum sulfate;

[0043] Step S102, adding a stabilizer to the aluminum sulfate aqueous solution to obtain a primary complexed mixed solution;

[0044] Step S103, adding a stabilizer to the aluminum sulfate aqueous solution to obtain a primary complexed mixed solution;

[0045] Step S104, adding magnesium sulfate to the secondary complexation mixed solution, stirring and dissolving to obtain the primary mixed solution;

[0046] Step S105, adding mineral acid, cellulose ether, and cyclodextrin-modified chitosan to the primary mixed liquid in sequence, mixing evenly, and cooling to obtain the alkali-free liquid quick-setting agent.

[0047] The stabilizer may be an organic carboxylic acid.

[0048] Wherein, the polyaluminum sulfate, magnesium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com