Porous gas producing agent molding pressing product and preparation process thereof

A technology of molded products and gas generating agents, which is applied in the field of airbag gas generators and can solve problems such as generator safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] The preparation technology of porous gas generating agent specifically comprises the following steps:

[0071] (1) Mix the raw material components comprising at least fuel and oxidant to obtain the first material; the mixing is carried out in a mixing device, and the mixing time is 15min. The mixing device can be a V-type mixer, a three-dimensional multi-directional motion mixer, Automatic lifting hopper mixer, ribbon mixer or acoustic resonance mixer; wherein, the fuel is guanidine nitrate with a content of 50%, the oxidant is basic copper nitrate with a content of 31.75%, and the auxiliary oxidant It is ammonium perchlorate, and its content is 2% respectively; The shape retaining agent is strontium titanate and strontium nitrate, and its content is 5.5% and 9.75% respectively; In addition, the first material also includes functional additives to help demoulding The additives are talcum powder and graphite, the contents of which are 0.75% and 0.25% respectively.

[00...

Embodiment 1

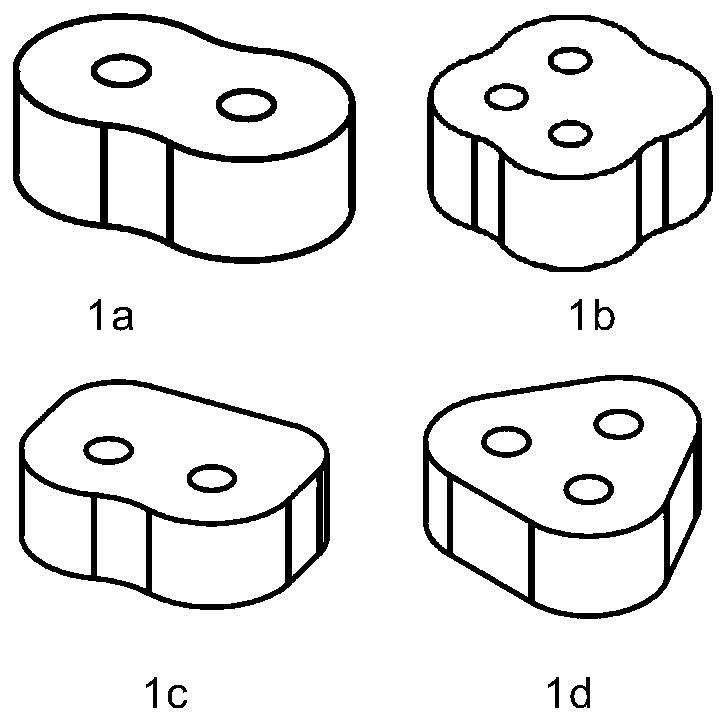

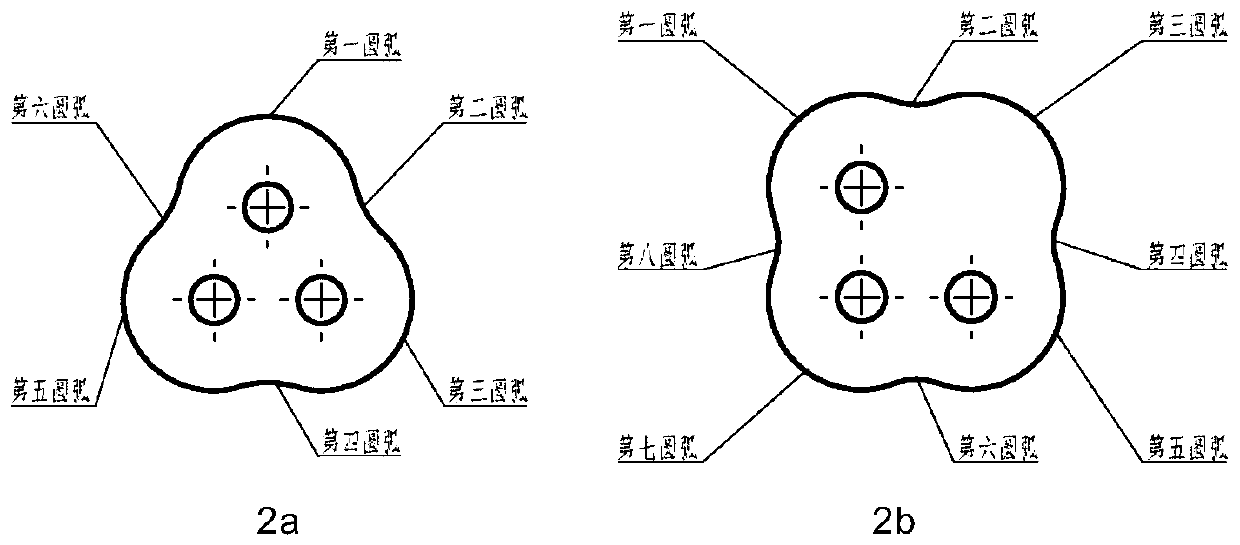

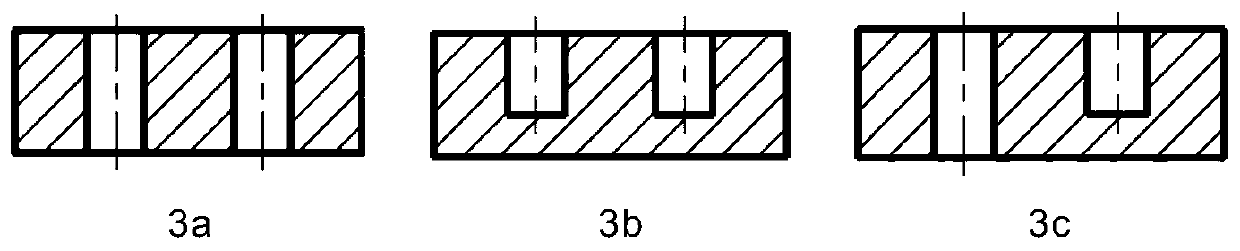

[0083] The real-time working capacity of the rotary tablet press is 8.0t. The cross-section and size of the prepared two-hole gas generating agent are as follows Figure 6 As shown, D=8.62mm, H=3mm; the hole is a cylindrical hole through the cylinder, and its diameter d=1.4mm.

[0084] Put the two-hole gas generating agent prepared above into the PAB test generator, and perform the P-t performance test. The test results are shown in Table 1. The P-t test curve is as follows Figure 10 shown.

[0085] Table 1

[0086]

[0087] as table 1 and Figure 10 As shown, the above-mentioned two-hole gas-generating agent is used in the PAB generator, the maximum pressure is 355KPa, the 10ms pressure is only 56KPa, the Slope1 (slope) is 6.43, and the Slope3 (slope) is 8.60. The impact force when the bag is unfolded is small, the gas production pressure is stable, the air bag is not easy to be torn and damaged, and the design strength of the air bag module assembly is low, thereby r...

Embodiment 2

[0089] The real-time working capacity of the rotary tablet press is 7.5t. The cross-section and size of the prepared three-porous gas-generating agent are as follows Figure 7 As shown, D=9.1mm, H=3mm; the hole is a cylindrical hole through the cylinder, and its diameter d=1.4mm.

[0090] Put the three-hole gas generating agent prepared above into the PAB test generator, and perform the P-t performance test. The test results are shown in Table 2. The P-t test curve is as follows Figure 10 shown.

[0091] Table 2

[0092]

[0093] as table 2 and Figure 10 As shown, the above-mentioned triangular three-hole gas generating agent is used in the PAB generator, the maximum pressure is 356KPa, the 10ms pressure is only 42kPa, the Slope1 (slope) is 5.00, and the Slope3 (slope) is 9.40. The impact force is small, and the air bag is not easy to tear and break. The high slope in the later stage helps the air bag to expand and maintain the full state for a long time. The design s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com