Method for coupling light hydrocarbon cracking sequential separation process and PDH process

A sequential separation and process technology, used in hydrocarbon cracking to produce hydrocarbons, distillation purification/separation, chemical instruments and methods, etc., can solve the problems of low yield of low-carbon olefins, lengthy separation process, low propylene output, etc., and achieve simplified separation. process, simplify the separation process, reduce the effect of the floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Using the method of coupling the light hydrocarbon cracking sequence separation process and PDH process of the present invention, the process flow is as follows: (1) PDH device reaction unit: the reaction unit mainly includes propane gasification tank, heating furnace, reactor, deoiling tower and other equipment. Fresh propane and recycled propane as raw materials are first gasified in the propane gasification tank, and then enter the dehydrogenation reactor after being preheated to the reaction temperature by the heating furnace. In the dehydrogenation reactor, propane undergoes dehydrogenation reaction to produce product gas such as propylene. The heavy components at the bottom of the propane gasification tank are sent to the deoiling tower, the propane separated from the top of the tower is returned to the propane gasification tank as a circulating material, and the bottom components are sent to the heating furnace as supplementary liquid fuel. (2) Cracking unit of e...

Embodiment 2

[0027]Coupling the sequential separation of 1 million tons / year ethylene unit with the PDH unit with a nominal capacity of 600,000 tons / year, keeping the ethylene output at 1 million tons / year, and the total propylene output at 736,200 tons / year, the product propylene / ethylene The ratio is 0.74. Compared with Comparative Example 2, the integrated coupling device increases the production of propylene products by 234.6%, consumes 2,114,600 tons of light hydrocarbon cracking raw materials per year, and consumes 629,300 tons of fresh propane raw materials per year, saving engineering construction investment of 397 million yuan, reducing Covers an area of 1.8 hectares.

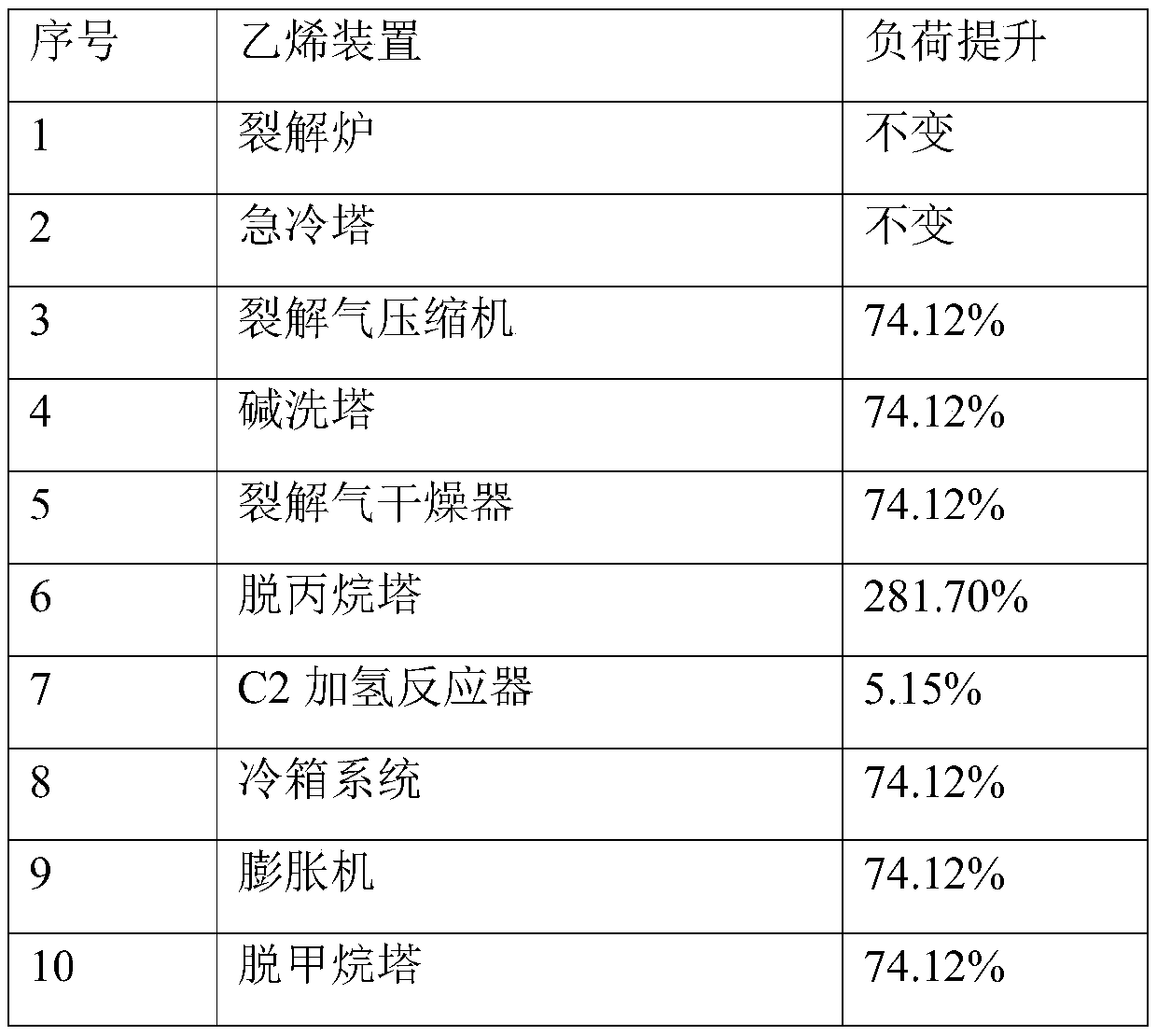

[0028] Table 2 Equipment load increase of ethylene plant

[0029]

[0030]

Embodiment 3

[0034] Coupling the sequentially separated 1.1 million tons / year ethylene unit with the PDH unit with a nominal capacity of 600,000 tons / year, keeping the ethylene output at 1.10 million tons / year, and the total propylene output at 758,200 tons / year, the product propylene / ethylene The ratio is 0.69. Compared with Comparative Example 3, the integrated coupling device increases the production of propylene products by 210.7%, consumes 2,328,800 tons of light hydrocarbon cracking raw materials per year, and consumes 629,300 tons of fresh propane raw materials per year, saving engineering construction investment of 426 million yuan, reducing Covers an area of 1.8 hectares.

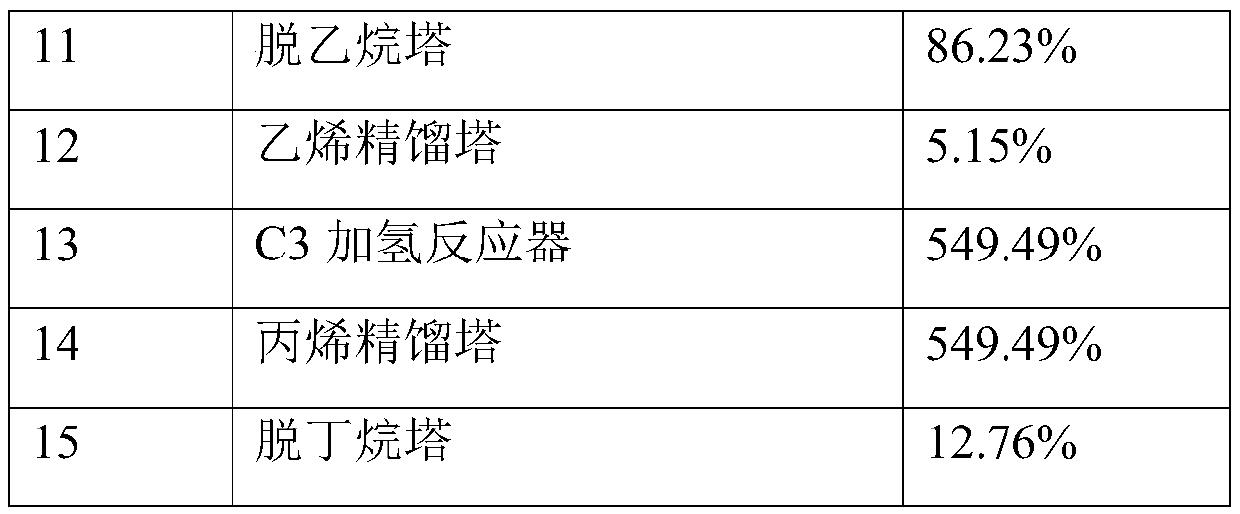

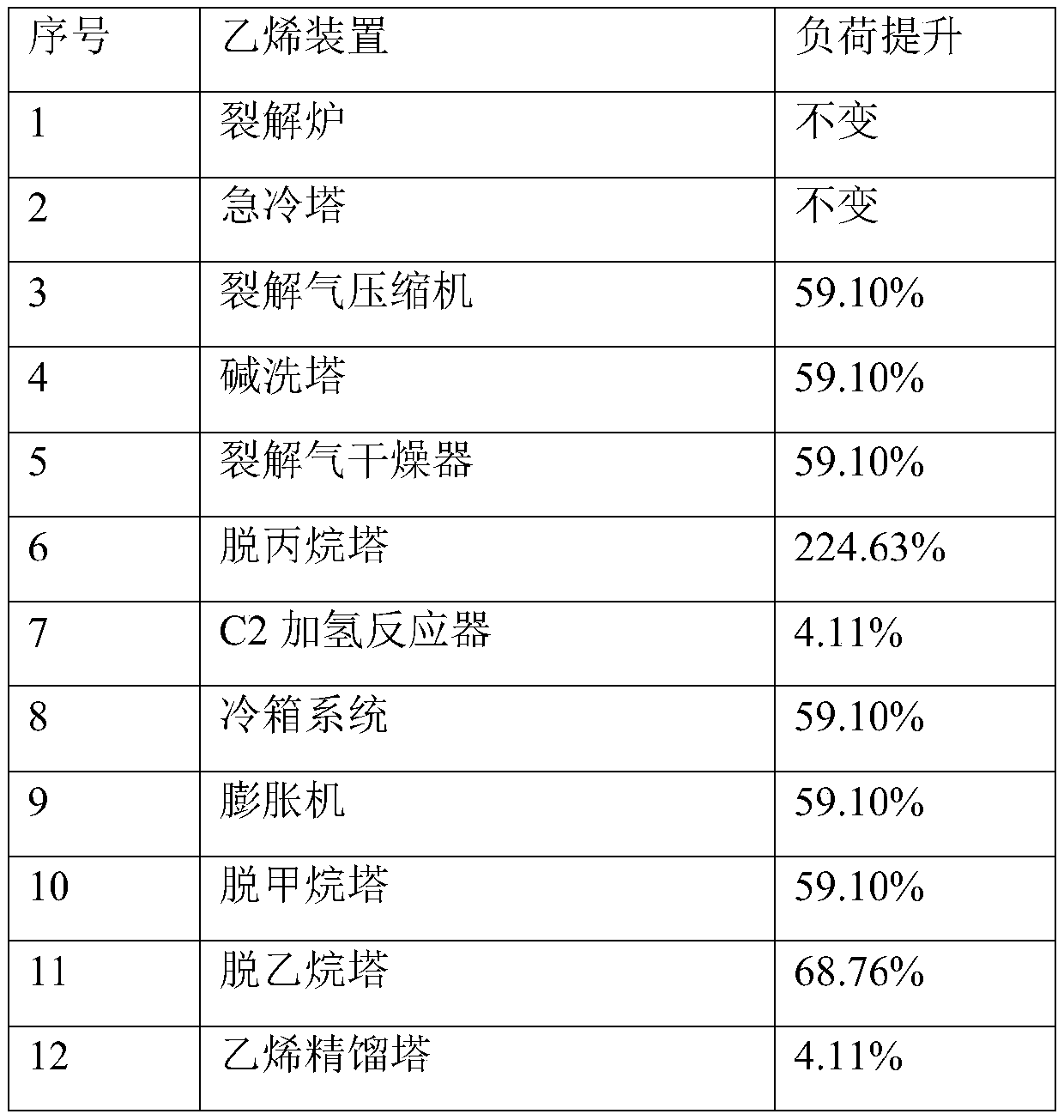

[0035] Table 3 Equipment load increase of ethylene plant

[0036]

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com