A preparation method of silk fibroin/hyaluronic acid double network hydrogel that can realize three-dimensional loading of cells

A technology of silk fibroin and hyaluronic acid, applied in prosthesis, medical science and other directions, can solve the problems of inability to meet the requirements of three-dimensional cartilage construction, three-dimensional loading of difficult cells, and long gelation time, and achieve adhesion, proliferation and In-situ three-dimensional loading, green and environmentally friendly gel forming method, and the effect of stable physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. A method for preparing a silk fibroin / hyaluronic acid double network hydrogel capable of three-dimensional loading of cells, comprising the steps of:

[0035] 1) Sterilization of materials: The silk fibroin solution and the modified hyaluronic acid solution were sterilized separately under the high temperature and high pressure environment of 120° C. and 0.25 MPa, and the sterilization time was 20 minutes.

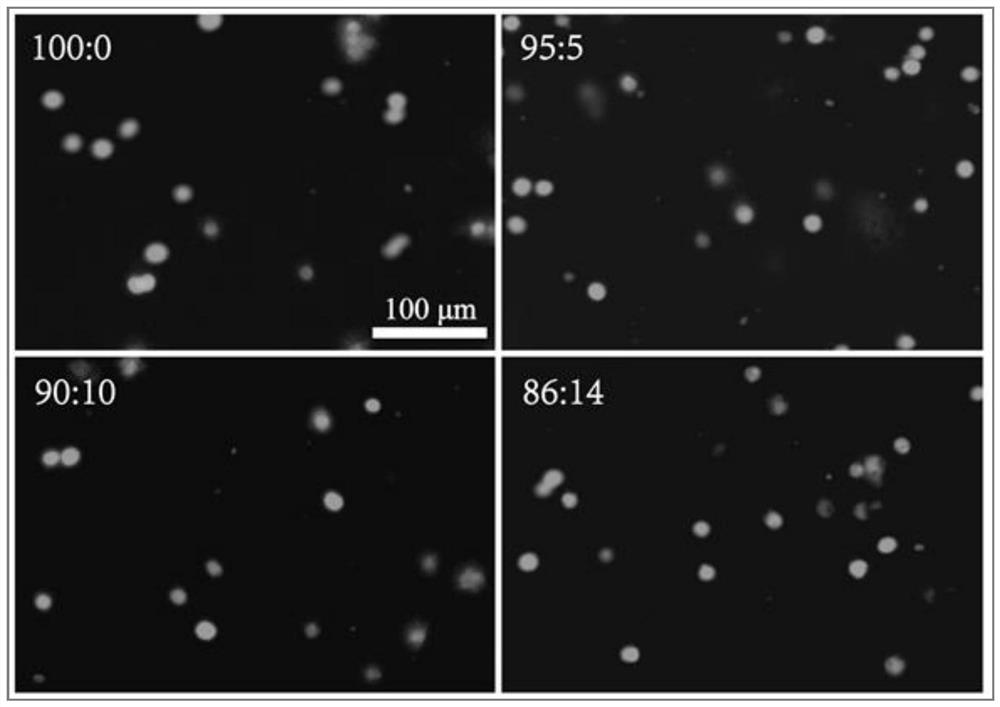

[0036] 2) Mix the silk fibroin solution with a mass volume fraction of 8% and the modified hyaluronic acid solution with a mass volume fraction of 2% according to a mass ratio of 10:0 to form a prepolymer solution, and add photoinitiated Agent 2-hydroxyl-4'-(2-hydroxyethoxy)-2-methyl propiophenone, wherein the mass volume ratio (g / ml) of photoinitiator and prepolymer solution is 0.5%;

[0037] 3) The solution obtained in step 2) was sonicated for 15 s, and the solution was fluid and transparent after sonication;

[0038] 4) After the solution obtained in step 3)...

Embodiment 2

[0040] 1. A method for preparing a silk fibroin / hyaluronic acid double network hydrogel capable of three-dimensional loading of cells, comprising the steps of:

[0041] 1) Sterilization of materials: adopt the method of high temperature and high pressure in advance, and sterilize the silk fibroin solution and the modified hyaluronic acid solution for 20 minutes at 120°C and 0.25Mpa high temperature and high pressure environment;

[0042] 2) The silk fibroin solution with a mass volume fraction of 8%, and the methacrylic anhydride-modified hyaluronic acid solution with a mass volume fraction of 2% are mixed according to a mass ratio of 9.5:0.5 to form a prepolymer solution, and the prepolymer solution is Add photoinitiator 2-hydroxyl-4'-(2-hydroxyethoxy)-2-methyl propiophenone, wherein, the mass volume ratio (g / ml) of photoinitiator and prepolymer solution is 0.5% ;

[0043]3) The solution obtained in step 2) was sonicated for 13s, and the solution was fluid and transparent af...

Embodiment 3

[0046] 1. A method for preparing a silk fibroin / hyaluronic acid double network hydrogel capable of encapsulating cells, comprising the steps of:

[0047] 1) Sterilization of materials: The silk fibroin solution and the modified hyaluronic acid solution were sterilized separately under the high temperature and high pressure environment of 120° C. and 0.25 MPa, and the sterilization time was 20 minutes.

[0048] 2) Mix the silk fibroin solution with a mass volume fraction of 8% and the modified hyaluronic acid solution with a mass volume fraction of 2% according to a mass ratio of 9:1 to form a prepolymer solution, and add photoinitiated Agent 2-hydroxyl-4'-(2-hydroxyethoxy)-2-methylpropiophenone, the mass volume ratio (g / ml) of photoinitiator and prepolymer solution is 0.5%;

[0049] 3) Ultrasonicate the solution obtained in step 2) for 12s, and the solution is fluid and transparent after ultrasonication;

[0050] 4) After the solution obtained in step 3) was repeatedly blown ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com