Fe-Mn-Cu-C system alloy and medical application thereof

A technology of fe-mn-cu-c and alloy, which is applied in the application field of implanted device materials, can solve the problems of increasing wound healing time, tissue structure deformation, affecting surgical effect, etc., to achieve the function of inhibiting vascular restenosis, reducing or Bacterial infection, the effect of increasing the corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

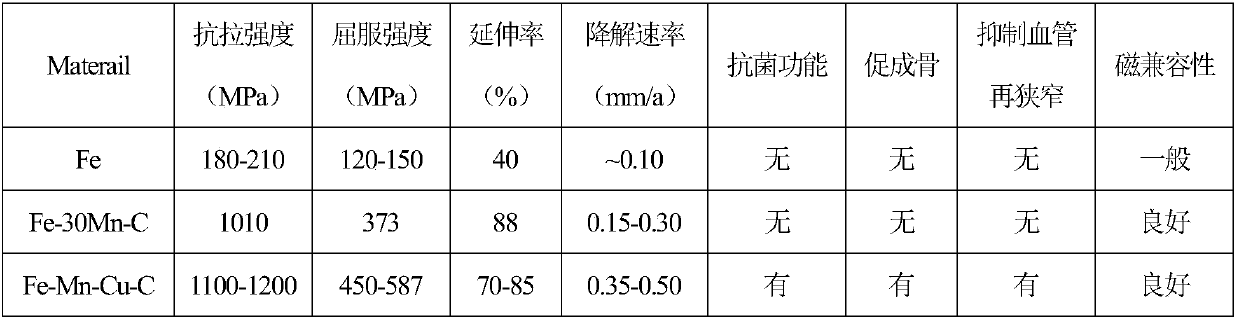

[0032] In this embodiment, the Fe-Mn-Cu-C quaternary Fe alloy has the following mass percentages: Mn: 28%, C: 0.8%, Cu: 1.0%, and the remainder is Fe, expressed as Fe-28Mn-0.8 C-1Cu. The Fe alloy ingot was made by vacuum induction melting, and after the ingot was kept at 1100°C for 1 hour, it was forged into a Φ20mm round bar.

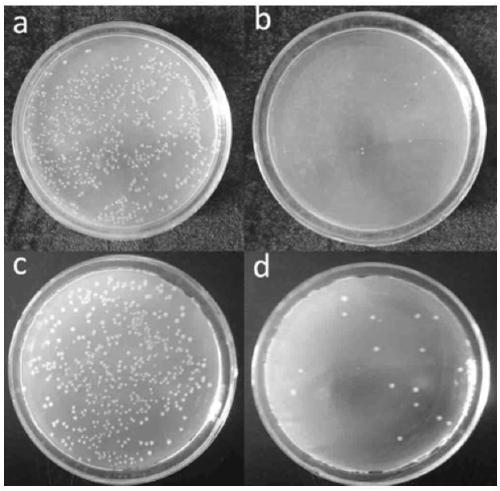

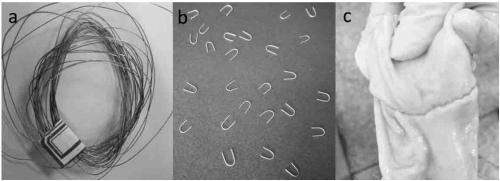

[0033] According to the GB / T 228-2002 standard, the Fe alloy bar is processed into a standard tensile sample, and its tensile strength is 1130MPa, yield strength is 453MPa, and elongation is 83%. According to the antibacterial test standard GB / T2591, the alloy has a strong bactericidal function, and the bactericidal rates for Staphylococcus aureus and Escherichia coli are 96.0% and 98.1%, respectively, seefigure 1 . According to the ASMT-G31 metal immersion standard, the degradation rate can reach 0.45mm / a when soaked in normal saline for 7 days, and the degradation rate drops to 0.35mm / a after 14 days. According to the ISO-10993 biological evaluatio...

Embodiment 2

[0035] In this embodiment, the Fe-Mn-Cu-C quaternary Fe alloy has the following mass percentages: Mn: 20%, C: 0.5%, Cu: 2.0%, and the rest is Fe, expressed as Fe-20Mn-0.5 C-2Cu. The Fe alloy ingot was made by vacuum induction melting, and the ingot was forged into a Φ20mm round bar after being kept at 1100°C for 1h.

[0036] According to the GB / T 228-2002 standard, the Fe alloy bar is processed into a standard tensile sample. The tensile strength is 1177MPa, the yield strength is 493MPa, and the elongation is 80%. According to the antibacterial test standard GB / T2591, it is measured that the alloy has a strong bactericidal function, and the bactericidal rates for Staphylococcus aureus and Escherichia coli are 99.2% and 99.9% respectively. According to the ASMT-G31 metal immersion standard, the degradation rate can reach 0.48mm / a when soaked in normal saline for 7 days, and the degradation rate drops to 0.39mm / a after 14 days. According to the ISO-10993 biological evaluation ...

Embodiment 3

[0038] In this embodiment, the Fe-Mn-Cu-C quaternary Fe alloy has the following mass percentages: Mn: 30%, C: 1.1%, Cu: 2.2%, and the rest is Fe, expressed as Fe-30Mn-1.1 C-2.2Cu. The Fe alloy ingot was made by vacuum induction melting, and the ingot was forged into a Φ20mm round bar after being kept at 1100°C for 1h.

[0039] According to the GB / T 228-2002 standard, the Fe alloy bar is processed into a standard tensile sample. The tensile strength is 1200MPa, the yield strength is 584MPa, and the elongation is 76%. According to the antibacterial test standard GB / T2591, it is measured that the alloy has a strong bactericidal function, and the bactericidal rates for Staphylococcus aureus and Escherichia coli are 99.9% and 99.9% respectively. According to the ASMT-G31 metal immersion standard, the degradation rate can reach 0.50mm / a when soaked in normal saline for 7 days, and the degradation rate drops to 0.43mm / a after 14 days. According to the ISO-10993 biological evaluatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com