Uncooled infrared focal plane with integrated broadband artificial surface and its fabrication method

An uncooled infrared and artificial surface technology, applied in the field of uncooled infrared focal plane and production, can solve the problems of increasing the complexity of the absorption layer and the limited performance of the multi-layer micro-bridge structure, so as to increase the complexity of the process and be beneficial to the The effect of large-scale low-cost preparation and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

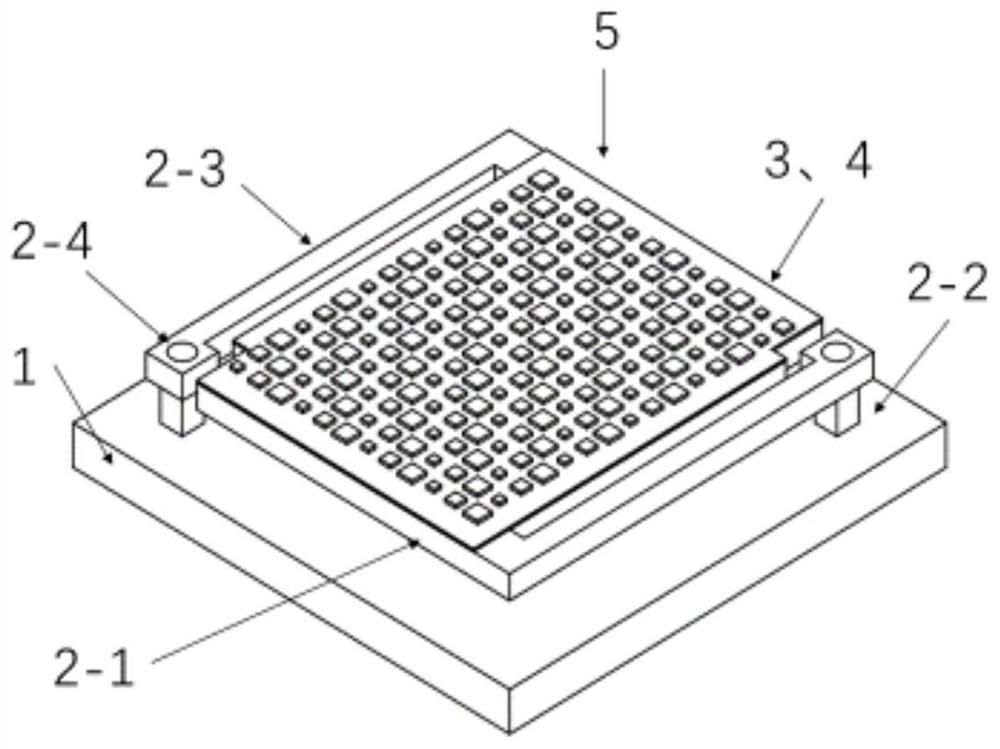

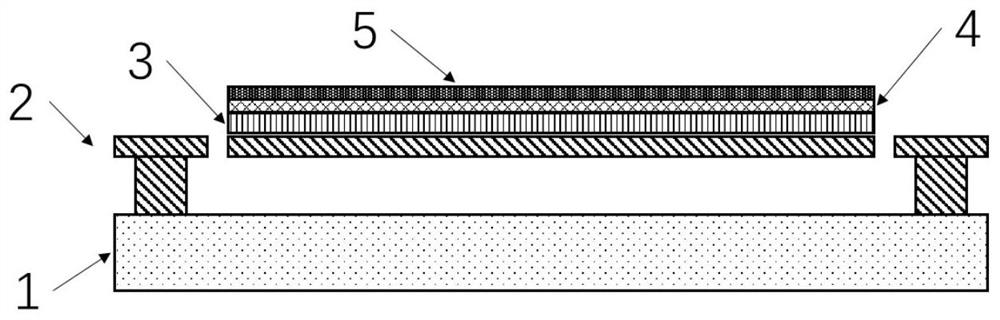

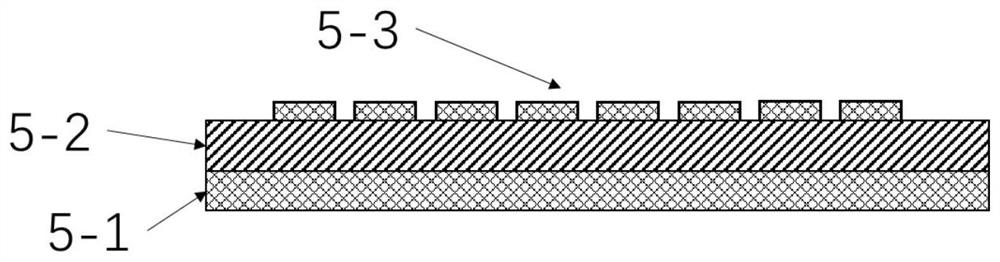

[0049] Uncooled infrared focal plane structures integrating broadband artificial surfaces such as figure 1 shown. The focal plane pixel unit metal microarray structure is as follows Figure 4 As shown, the first dielectric layer 5-2-1 is made of germanium (Ge), the metal microarray 5-3 is made of gold (Au), and each metal unit is composed of circular resonant units 5-3-1 of nine sizes. 3×3 superpixels. The diameters of the circular resonance units 5-3-1 are 0.8 micron, 0.9 micron, 1.0 micron, 1.1 micron, 1.2 micron, 1.3 micron, 1.4 micron, 1.5 micron, 1.6 micron respectively. Nine circular resonant units 5-3-1 with different structures realize infrared absorption at different wavelengths. Through the combination of nine bands, the infrared radiation with a wavelength of 8 microns to 14 microns is captured by the composite absorption film layer 5, and the The light energy is converted into the Joule heat of the metal structure and the phonon absorption of the dielectric stru...

Embodiment 2

[0061] Uncooled infrared focal plane structures integrating broadband artificial surfaces such as figure 1 shown. The focal plane pixel unit metal microarray structure is as follows Figure 5 As shown, the second dielectric layer 5-2-2 is made of silicon (Si), the metal microarray 5-3 is made of gold (Au), each metal unit is formed by nesting three structures, and the outermost metal ring edge The length is 3 microns, the side length of the inner metal ring is 2 microns, the line width of the inner and outer metal rings is 500 nm, and the side length of the innermost rectangular unit is 1 micron line width. The resonant wavelength of the three structural units 5-3-2 changes with the increase of the side length. Through the combination of the absorption wavelengths of the three structural units 5-3-2, the nested structure has a wavelength of 8 microns to 12 microns. The infrared radiation is captured by the absorbing film layer, and the light energy is converted into the Joul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com