Method for preparing catalyst by deep processing of rare earth tailings and application of catalyst

A technology of rare earth tailings and catalysts, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of fine embedding, harm to human health, poor toxicity resistance, etc., and increase the number of active sites and oxygen vacancies, avoid resource waste and environmental pollution, and improve catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

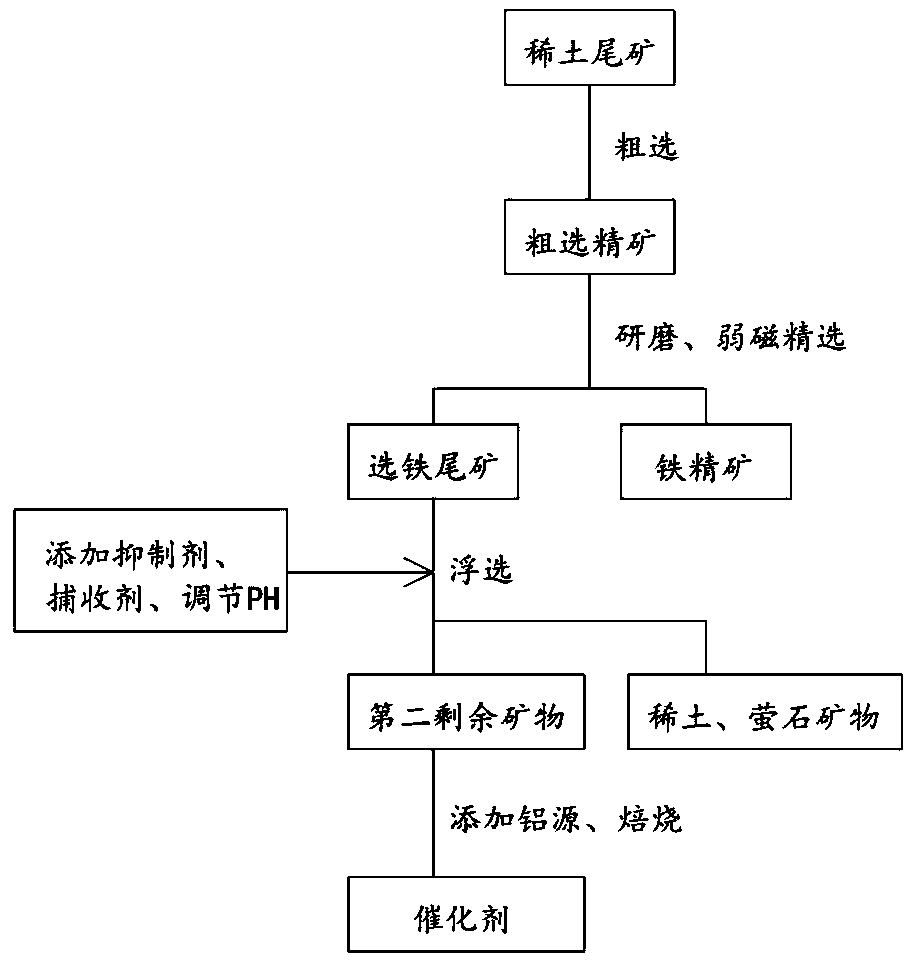

[0021] (1) Weak magnetic separation: the rare earth tailings in the rare earth recovery process are used as the raw material for iron ore recovery. The slurry flow rate is 0.5cm / s, the slurry concentration is a liquid-solid ratio of 15:1, and the roasting temperature is 500°C. The time is 80min, and the roughing is carried out under the condition of the magnetic field strength of 120MT, and the roughing concentrate is obtained;

[0022] Concentrate the obtained rough concentrate: grind the rough concentrate through a mortar to make the rare earth minerals sintered with the iron minerals partly dissociate, and then the slurry flow rate is 0.5cm / s, the slurry Concentration of liquid-solid ratio of 15:1, magnetic field strength of 50MT under the condition of weak magnetic concentration, to obtain iron concentrate and iron tailings;

[0023] (2) Flotation: add inhibitors and collectors to the iron tailings obtained in step (1), adjust the pH value to 4, and separate the rare earth...

Embodiment 2

[0029] (1) Weak magnetic separation: the rare earth tailings in the rare earth recovery process are used as the raw material for iron ore recovery. The slurry flow rate is 0.6cm / s, the slurry concentration is a liquid-solid ratio of 18:1, and the roasting temperature is 580°C. The time is 70min, and the roughing is carried out under the condition of the magnetic field strength of 140MT, and the roughing concentrate is obtained;

[0030] Concentrate the obtained rough concentrate: grind the rough concentrate through a mortar to make the rare earth minerals sintered together with the iron minerals partly dissociate, and then the slurry flow rate is 0.6cm / s, the slurry The concentration is liquid-solid ratio 18:1, and the magnetic field strength is 70MT, and the weak magnetic concentration is carried out to obtain iron concentrate and iron tailings;

[0031] (2) Flotation: Add inhibitors and collectors to the iron tailings obtained in step (1), adjust the pH value to 5, and separ...

Embodiment 3

[0037] (1) Weak magnetic separation: the rare earth tailings in the rare earth recovery process are used as the raw material for iron ore recovery. The slurry flow rate is 0.7cm / s, the slurry concentration is a liquid-solid ratio of 22:1, and the roasting temperature is 650°C. The time is 60min, and the roughing is carried out under the condition of the magnetic field strength of 160MT to obtain the roughing concentrate;

[0038] Concentrate the obtained rough concentrate: grind the rough concentrate through a mortar to make the rare earth minerals sintered with the iron minerals partly dissociate, and then the slurry flow rate is 0.7cm / s, the slurry The concentration is liquid-solid ratio 22:1, and the magnetic field strength is 90MT, and the weak magnetic concentration is carried out to obtain iron concentrate and iron tailings;

[0039] (2) Flotation: add inhibitors and collectors to the iron tailings obtained in step (1), adjust the pH value to 6, and separate the rare ear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com