A method for preparing composite artificial stone profiles by calendering yellow phosphorus slag

A calendering method and artificial stone technology, which is applied in the field of preparing composite artificial stone profiles by yellow phosphorus slag calendering method, can solve the problems of falling off cost, easy peeling of the surface layer, etc., and achieve the effects of improving strength, solving easy peeling and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0031] see Figure 1-4 Shown, the specific embodiment that the present invention provides is as follows:

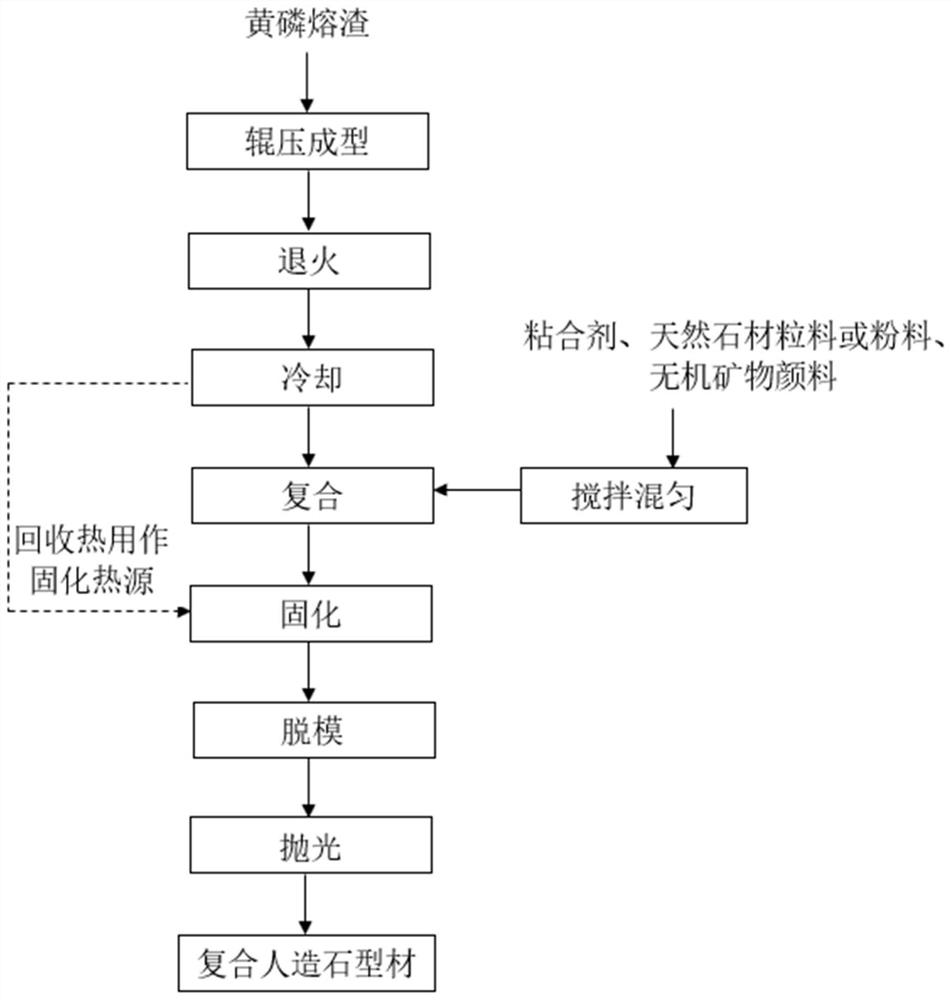

[0032] A method of preparing a composite artificial stone profile by a yellow phosphorus slag calendering method of the present embodiment, the method comprising:

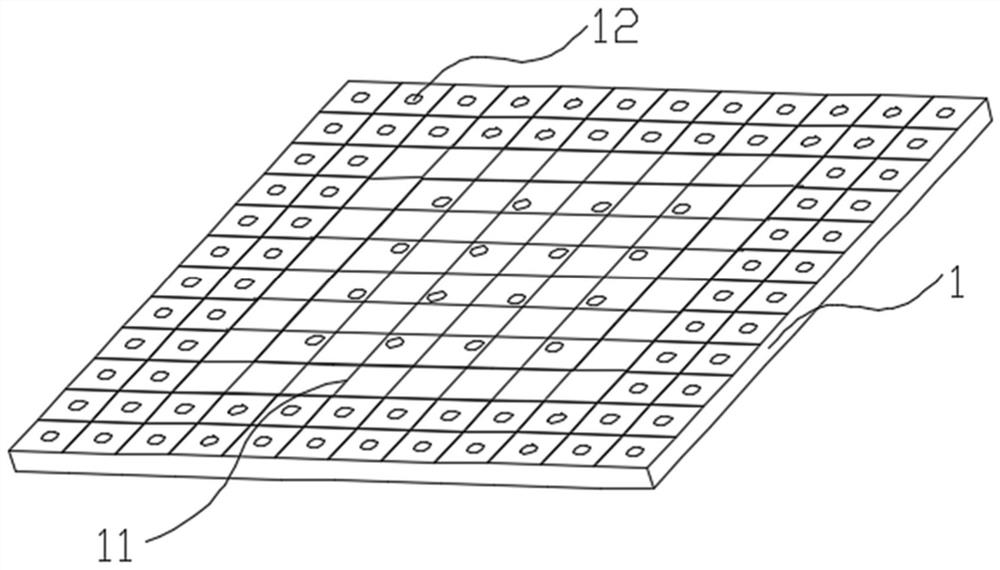

[0033]S1. Preparation of the base layer, using a calender to roll the yellow phosphorus slag into a plate with lines 11 on the surface and tapered anchor holes 12 running through the upper and lower surfaces; the plate is then annealed and cooled to obtain the base profile 1;

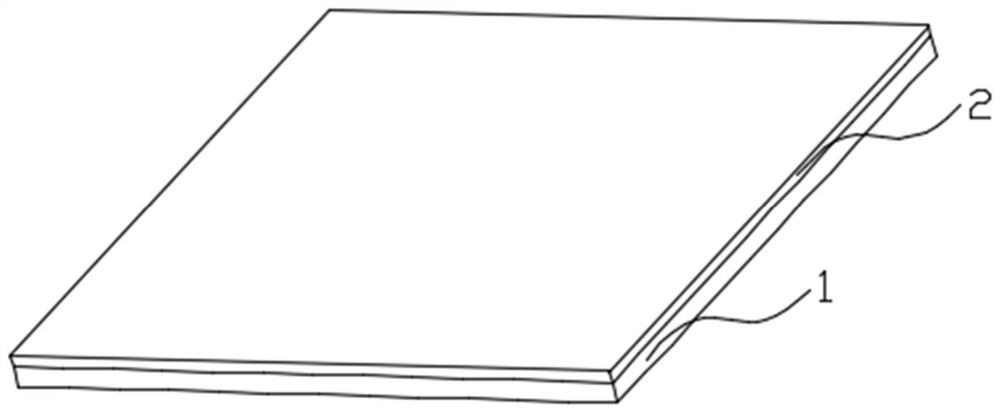

[0034] S2. Surface layer preparation and composite artificial stone profile molding, mixing the adhesive with natural stone granules or powder, and inorganic mineral pigments to obtain a mixture, and putting the base layer profile into the bottom of the molding mold, and then injecting the mixture into molding The surface layer 2 is uniformly covered on the surface where the tapered anchor hole diameter of the base profile is at the sm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com