Method for treating wastewater formed by producing hydrocortisone by adopting chromic anhydride and application of method

A technology of hydrocortisone and treatment methods, applied in chemical instruments and methods, inorganic chemistry, organic chemistry, etc., can solve the problems of chromic anhydride toxicity, etc., achieve the effect of reducing environmental protection pressure, reducing material waste, and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

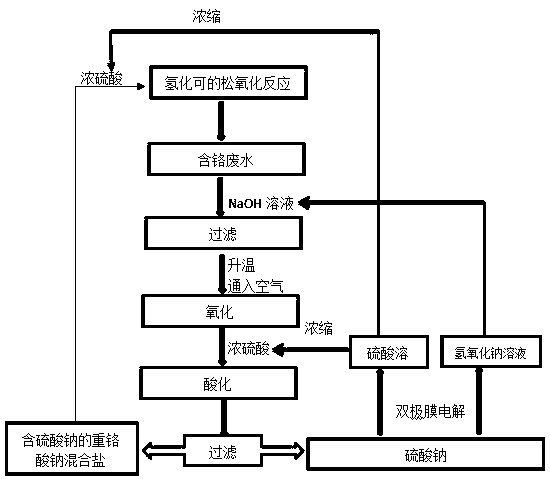

Image

Examples

Embodiment 1

[0034]1. Take 8L of waste water from the washing section after chromic anhydride oxidation and add it to the reactor, then add sodium hydroxide to the reactor, adjust the pH value of the mixed system to 7.8, filter the insoluble matter through a filter, and then raise the temperature to 85 °C, blow in clean air until the solution turns dark brown, and keep blowing in air for 1 hour.

[0035] 2. Sulfuric acid oxidation:

[0036] Evaporate the above reactor to remove moisture. When the material is viscous, slowly add sulfuric acid aqueous solution with a concentration of 70% (wt) to the above solution until the pH value of the mixed system reaches 6.8. After the reaction, the solution will CrO 4 2- fully converted to Cr 2 o 7 2- , and form sodium sulfate crystals.

[0037] Then filter to remove the crystals of sodium sulfate, and dry the remaining solution to obtain a mixture containing sodium sulfate and sodium dichromate.

[0038] The products are respectively: 285 g of...

Embodiment 2

[0040] 1. Take 10L of wastewater from the washing section after oxidation of chromic anhydride, add sodium hydroxide, adjust the pH value to 8.5, filter through a filter to remove insoluble matter, then raise the temperature to 75°C, blow in clean air until the solution turns dark brown brown and continue to sparge with air for 1.5 hours.

[0041] 3. Sulfuric acid acidification dehydration:

[0042] Evaporate the above reactor to remove moisture. When the material is viscous, slowly add sulfuric acid aqueous solution with a concentration of 60% (wt) to the above solution dropwise, adjust the pH to 7, and react to make the CrO in the solution 4 2- fully converted to Cr 2 o 7 2- , and form sodium sulfate crystals.

[0043] Crystals of sodium sulfate were removed by filtration, and the obtained aqueous solution was dried to obtain a mixture containing sodium sulfate and sodium dichromate.

[0044] The products are respectively: 350 g of sodium sulfate crystals, and 730 g of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com