Polymer film containing alkene telluride, and preparation method and application of polymer film

A polymer film and polymer technology, applied in the field of lasers, can solve problems such as unfavorable large energy, high-power ultra-short pulses, limited output, and inability to work normally, achieve excellent light absorption efficiency and saturable absorption characteristics, and improve stability. and service life, the effect of improving nonlinear optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

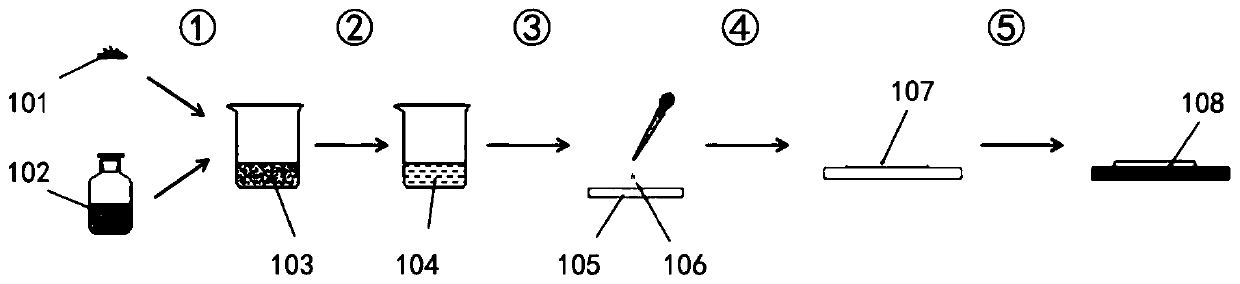

[0054] The second aspect of the present invention provides a method for preparing a tellurene-containing polymer film, comprising:

[0055] Provide a polymer and tellurene dispersion, and mix the polymer and tellurene dispersion uniformly to obtain a mixed solution;

[0056] The mixed liquid is dropped onto the substrate, and after being vacuum-dried at 20° C. to 50° C. to form a film on the substrate, and then peeled off to obtain a tellurene-containing polymer film.

[0057] In the embodiment of the present invention, the tellurene dispersion liquid is mixed with the polymer, and the mixed liquid is obtained after ultrasonic dispersion.

[0058] In the embodiment of the present invention, the tellurene-containing polymer film is formed by mixing the tellurene dispersion liquid with the polymer, stirring uniformly, dripping the solution, and drying.

[0059] In an embodiment of the present invention, the solute of the tellurene dispersion may be, but not limited to, telluren...

Embodiment 1

[0091] A kind of saturable absorber preparation method of tellurene-containing polymer film

[0092] Provide a solution containing tellurene nanosheets and polyvinylpyrrolidone, mix 1mg of polyvinylpyrrolidone powder and 10mL of a solution containing tellurene nanosheets, and stir well and uniformly for 1 hour to obtain a mixed solution; drop the mixed solution onto a polytetrafluoroethylene liner After standing and drying at 40°C under vacuum for 2 hours, a tellurene-containing polymer film was formed on the polytetrafluoroethylene substrate, and the tellurene-containing polymer film was peeled off from the polytetrafluoroethylene substrate. , to obtain tellurene-containing polymer films.

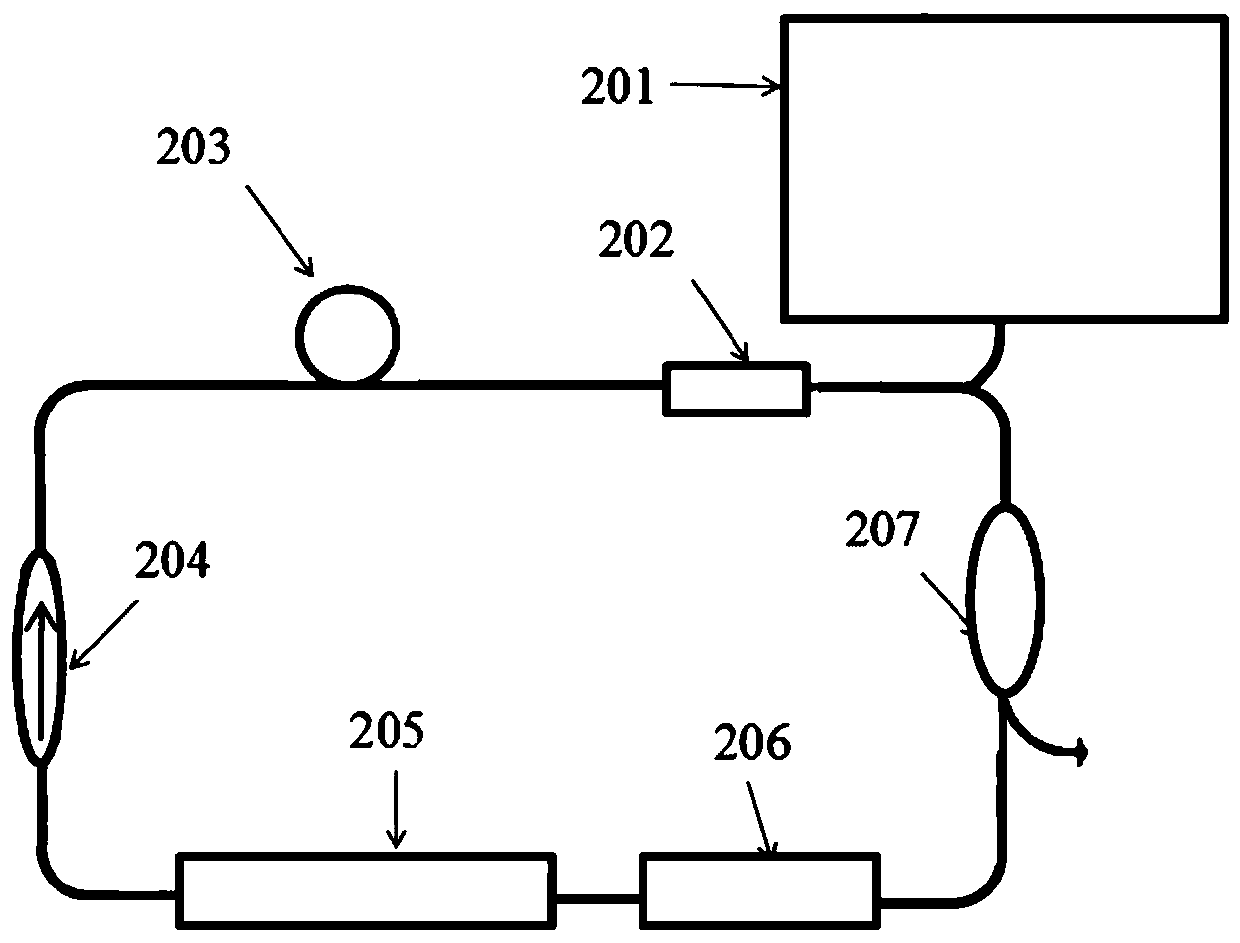

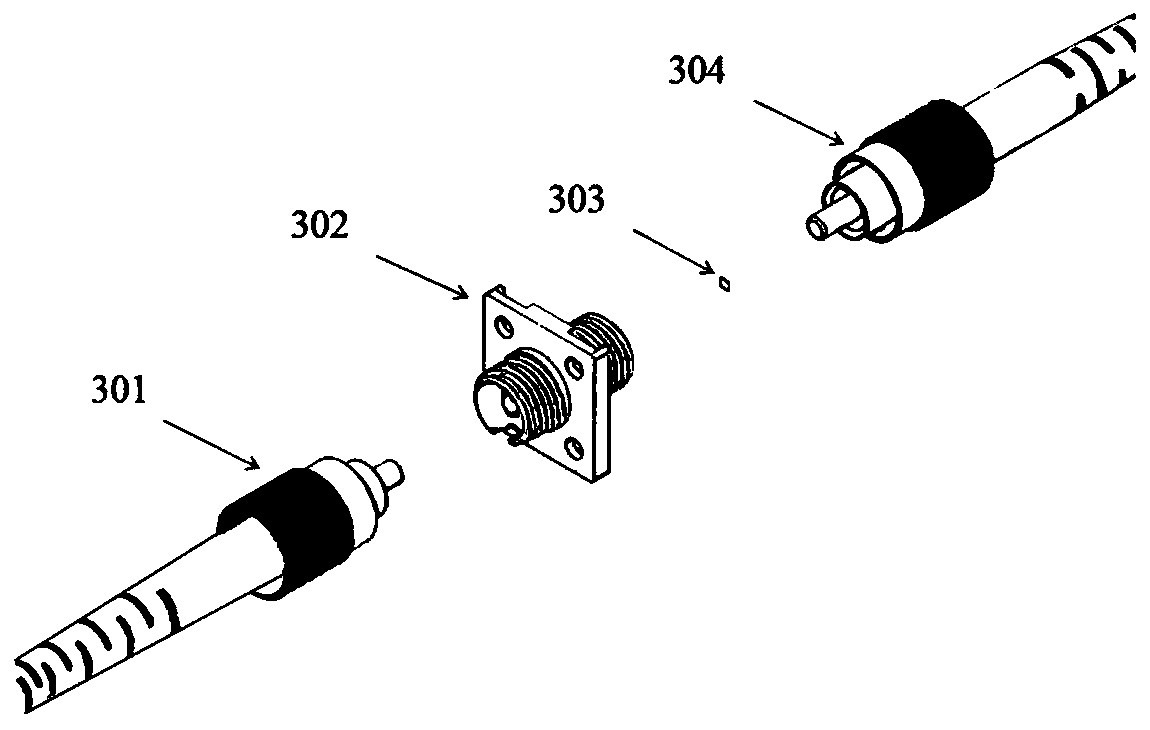

[0093] The obtained tellurene-containing polymer film is cut, and the area obtained by cutting is similar to the area of the end face of the optical fiber, and is smaller than the area of the end face of the optical fiber as far as possible. The cut tellurene-containing polymer film i...

Embodiment 2

[0098] A kind of saturable absorber preparation method of tellurene-containing polymer film

[0099] Provide tellurene-containing nanosheet solution and polystyrene, the lateral dimension of tellurene nanosheet is 8 μm, the thickness is 40nm, the concentration of tellurene-containing nanosheet solution is 0.2mg / mL, 1mg polystyrene and 15mL tellurene-containing The solution of nanosheets was mixed and stirred uniformly for 2 hours to obtain a mixed solution; the mixed solution was dropped on a polytetrafluoroethylene substrate, and after standing and drying at 30°C for 2.5 hours under vacuum conditions, the mixed solution was obtained on the polytetrafluoroethylene substrate. A tellurene-containing polymer film is formed on the substrate, and the tellurene-containing polymer film is peeled off from the polytetrafluoroethylene substrate to obtain a tellurene-containing polymer film with a thickness of 3 μm.

[0100] The tellurene-containing polymer film is transferred to the end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com