Preparation method of high-temperature-resistant and high-strength material

A high-strength, high-temperature-resistant technology, applied in the field of high-temperature-resistant materials, can solve the problems of high temperature-resistant properties and strength that cannot meet people's requirements, and achieve the effects of short preparation cycle, convenient molding and low water absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

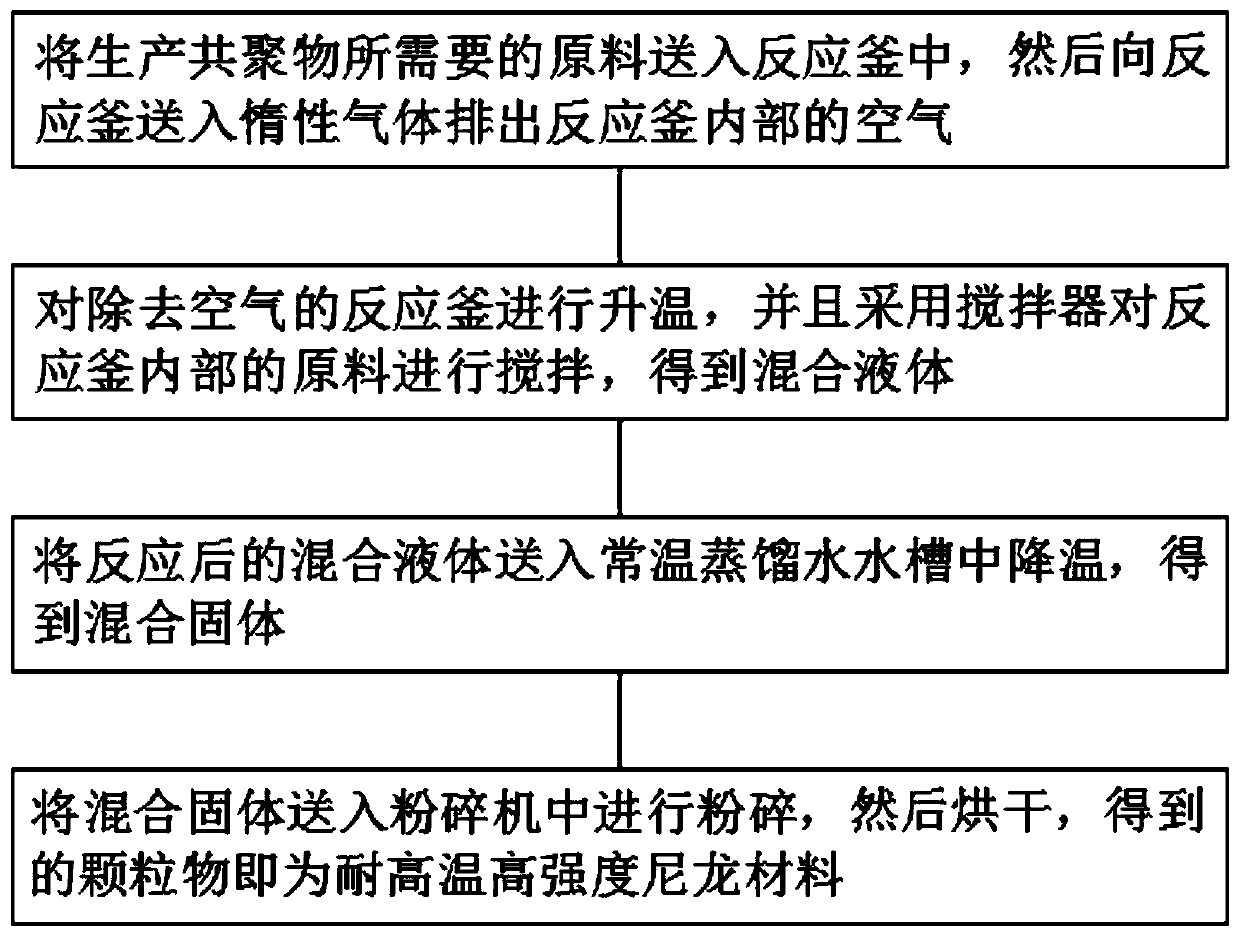

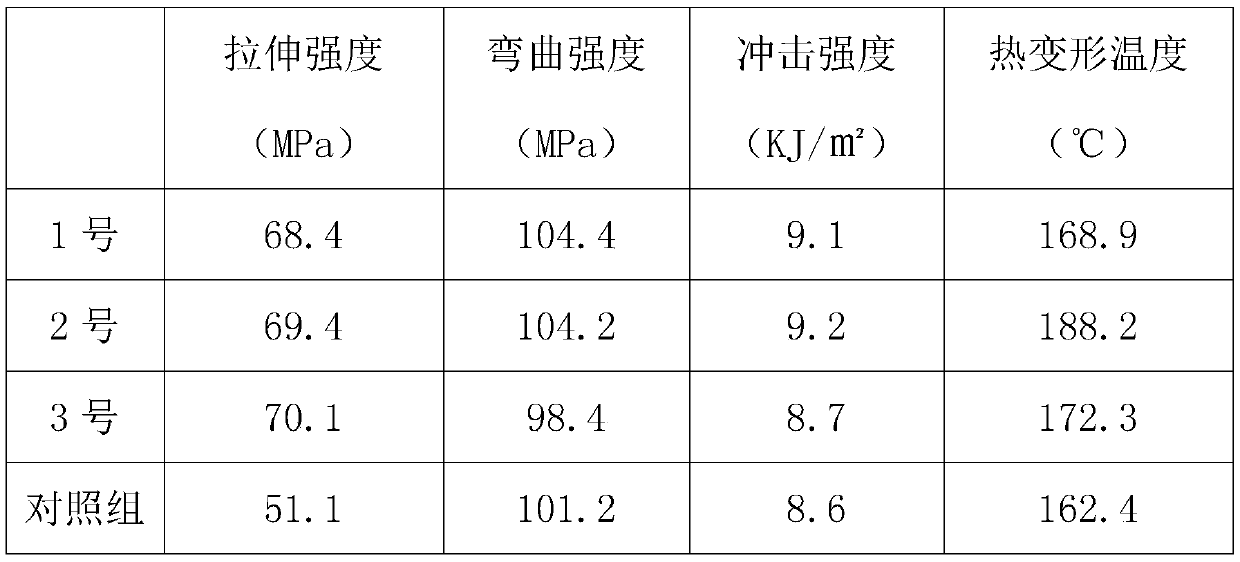

[0026] like figure 1 As shown, a preparation method of a high-temperature-resistant high-strength material is made of the following components by weight: 46 parts of polyhexamethylene adipamide, 56 parts of polyhexamethylene terephthalamide, polyphthalamide 32 parts of formamide, 66 parts of caprolactam, 21 parts of methyl silicone oil, 17 parts of m-cresol, 1.1 parts of catalyst, and 1.3 parts of lubricant.

[0027] A method for preparing a high-temperature-resistant high-strength material, comprising the following steps:

[0028] (1) Send the raw materials required for the production of the copolymer into the reactor, and then send inert gas into the reactor to discharge the air inside the reactor. Before the raw materials are sent into the reactor, they need to be sent to the V-type powder mixing machine Mixing is performed at a speed of 28 r / min for 8 minutes, and the inert gas is one of nitrogen, helium, neon, argon, and krypton.

[0029] (2), heat up the reaction kettl...

Embodiment 2

[0037] A method for preparing a high-temperature-resistant high-strength material, which is made of the following components in parts by weight: 48 parts of polyhexamethylene adipamide, 57 parts of polyhexamethylene terephthalamide, 34 parts of polyphthalamide 70 parts of caprolactam, 22 parts of methyl silicone oil, 18 parts of m-cresol, 1.2 parts of catalyst, and 1.5 parts of lubricant.

[0038] A method for preparing a high-temperature-resistant high-strength material, comprising the following steps:

[0039] (1) Send the raw materials required for the production of the copolymer into the reactor, and then send inert gas into the reactor to discharge the air inside the reactor. Before the raw materials are sent into the reactor, they need to be sent to the V-type powder mixing machine Mixing is performed at a speed of 26 r / min for 8 minutes, and the inert gas is one of nitrogen, helium, neon, argon, and krypton.

[0040] (2), heat up the reaction kettle that removes the ai...

Embodiment 3

[0048] A method for preparing a high-temperature-resistant high-strength material, which is made of the following components in parts by weight: 49 parts of polyhexamethylene adipamide, 57 parts of polyhexamethylene terephthalamide, 35 parts of polyphthalamide 71 parts of caprolactam, 23 parts of methyl silicone oil, 18 parts of m-cresol, 1.3 parts of catalyst, and 1.6 parts of lubricant.

[0049] A method for preparing a high-temperature-resistant high-strength material, comprising the following steps:

[0050] (1) Send the raw materials required for the production of the copolymer into the reactor, and then send inert gas into the reactor to discharge the air inside the reactor. Before the raw materials are sent into the reactor, they need to be sent to the V-type powder mixing machine Mixing is performed at a speed of 26 r / min for 8 minutes, and the inert gas is one of nitrogen, helium, neon, argon, and krypton.

[0051] (2), heat up the reaction kettle that removes the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com