A water-resistant and anti-corrosion soybean protein adhesive and preparation method thereof

A soybean protein glue and adhesive technology, which is applied in the preparation of protein adhesives, animal glue or gelatin, adhesives, etc., can solve the problems of harming human health, insignificant effect, toxic gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of a water-resistant and anti-corrosion soybean protein adhesive, comprising the following steps:

[0033] (1) Disperse 0.01g of modified aramid fiber in 85g of distilled water, and disperse with ultrasonic assistance for 30 minutes;

[0034] (2) Evenly disperse 15g of soybean protein isolate powder in the fiber dispersion obtained in step (1), then raise the temperature of the water bath to 30°C and stir for 20 minutes;

[0035] (3) Add 3g of cross-linking agent to the mixture obtained in step (2), and stir for 10 minutes to disperse evenly.

[0036] The preparation method of above-mentioned modified aramid fiber is as follows:

[0037] Dissolve 0.18g catechol, 0.09g pyrogallol and 0.22g tetraethylenepentamine in 200g distilled water, adjust the pH to 9.0, add 0.1g aramid fiber and stir at room temperature for 5 hours, filter, wash, Dry at 60° C. for 24 hours to obtain modified aramid fibers.

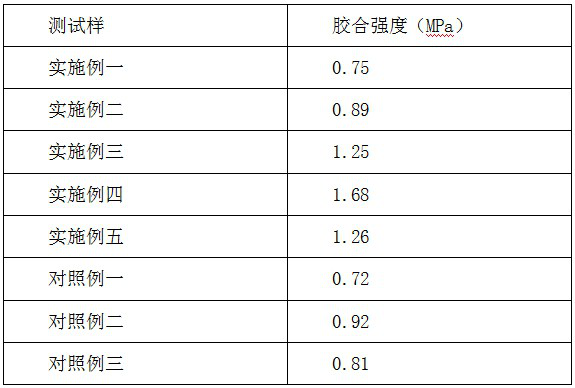

[0038] The performance and quality indicators of th...

Embodiment 2

[0040] A preparation method of a water-resistant and anti-corrosion soybean protein adhesive, comprising the following steps:

[0041] (1) Disperse 0.03g of modified aramid fibers in 85g of distilled water, and disperse with ultrasonic assistance for 30 minutes;

[0042] (2) Evenly disperse 15g of soybean protein isolate powder in the fiber dispersion obtained in step (1), then raise the temperature of the water bath to 30°C and stir for 20 minutes;

[0043] (3) Add 3g of cross-linking agent to the mixture obtained in step (2), and stir for 10 minutes to disperse evenly.

[0044] The preparation method of above-mentioned modified aramid fiber is as follows:

[0045] Dissolve 0.18g catechol, 0.09g pyrogallol and 0.22g tetraethylenepentamine in 200g distilled water, adjust the pH to 9.0, add 0.1g aramid fiber and stir at room temperature for 5 hours, filter, wash, Dry at 60° C. for 24 hours to obtain modified aramid fibers.

[0046] The performance and quality indicators of t...

Embodiment 3

[0048] A preparation method of a water-resistant and anti-corrosion soybean protein adhesive, comprising the following steps:

[0049] (1) Disperse 0.05g of modified aramid fibers in 85g of distilled water, and disperse with ultrasonic assistance for 30 minutes;

[0050] (2) Evenly disperse 15g of soybean protein isolate powder in the fiber dispersion obtained in step (1), then raise the temperature of the water bath to 30°C and stir for 20 minutes;

[0051] (3) Add 3g of cross-linking agent to the mixture obtained in step (2), and stir for 10 minutes to disperse evenly.

[0052] The preparation method of above-mentioned modified aramid fiber is as follows:

[0053] Dissolve 0.18g catechol, 0.09g pyrogallol and 0.22g tetraethylenepentamine in 200g distilled water, adjust the pH to 9.0, add 0.1g aramid fiber and stir at room temperature for 5 hours, filter, wash, Dry at 60° C. for 24 hours to obtain modified aramid fibers.

[0054] The performance and quality indicators of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com