Active molecule coupled cloth bag catalytic filtration process for incineration flue gas near-zero emission

An active molecule and near-zero emission technology, which is applied in the direction of combined devices, separation methods, and dispersed particle separation, can solve the problems of unreachable, low adsorption efficiency of acidic substances, and limited removal rate of dioxins, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

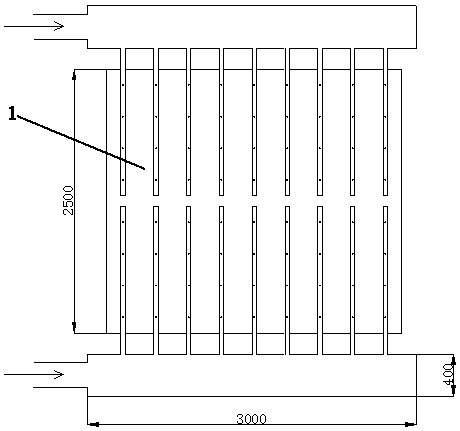

[0014] The system process route is traditional bag filter flue gas → active molecule generator → filter catalytic bag filter → heat exchanger → high-efficiency scrubber → wet electrostatic precipitator → heat exchanger.

[0015] The flue gas from the waste incineration power generation boiler, after the semi-dry deacidification of the original process and the traditional bag filter, the flue gas is fully mixed with the active molecules first, and other free particles are produced, and enters the catalytic filter bag. Under the action of the surface filter catalyst, pollutants such as NO and dioxin are strongly catalyzed and oxidized into soluble or easily absorbed and removed molecules, and then enter the high-efficiency scrubber to be effectively absorbed and removed, and finally enter the wet electrostatic precipitator to further remove fine particles and Fog droplets, to achieve near-zero emissions of acidic substances, dioxins, dust particles and mist droplets in the flue g...

Embodiment 2

[0017] The filter material structure in the filter catalytic bag filter consists of three layers: 1) filter layer, made of e-PTFE (polytetrafluoroethylene); 2) middle layer; 3) (nanofiber) catalytic layer. The filter material structure consists of the following three parts:

[0018] (1) The filter layer is made of e-PTFE (polytetrafluoroethylene),

[0019] (2) The TiO2 film layer in the middle layer uses electrospinning nanotechnology to form TiO2 into fibers with a diameter of 1-2nm, and then weaves the fibers into a film.

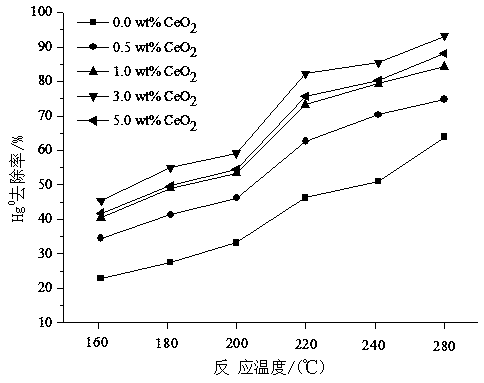

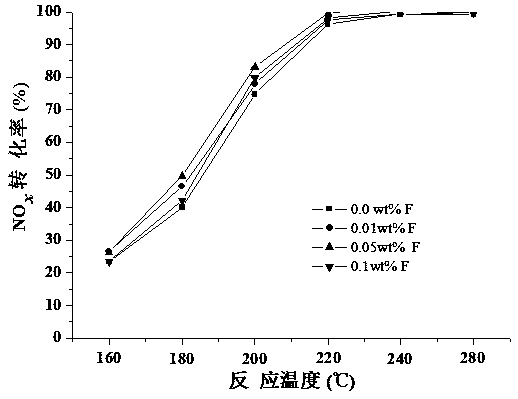

[0020] The (nanofiber) catalytic layer is composed of an active layer (V2O5 / CeO2) and a carrier layer (TiO2 / WO3). V2O5 / CeO2 and TiO2 / WO3 are sprayed into 0.5~1nm fibers by electrospinning respectively, and then woven into Nano film layer. Catalyst activity test see figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com