Automatic wire rod molding machine with automatic discharging

An automatic forming machine and automatic unloading technology, applied in the field of wire material processing, can solve the problems of high labor cost and resources, reduce the manufacturer's profit, and the impact of manufacturer market competition, so as to improve the processing quality, reduce the use of manpower, reduce the The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

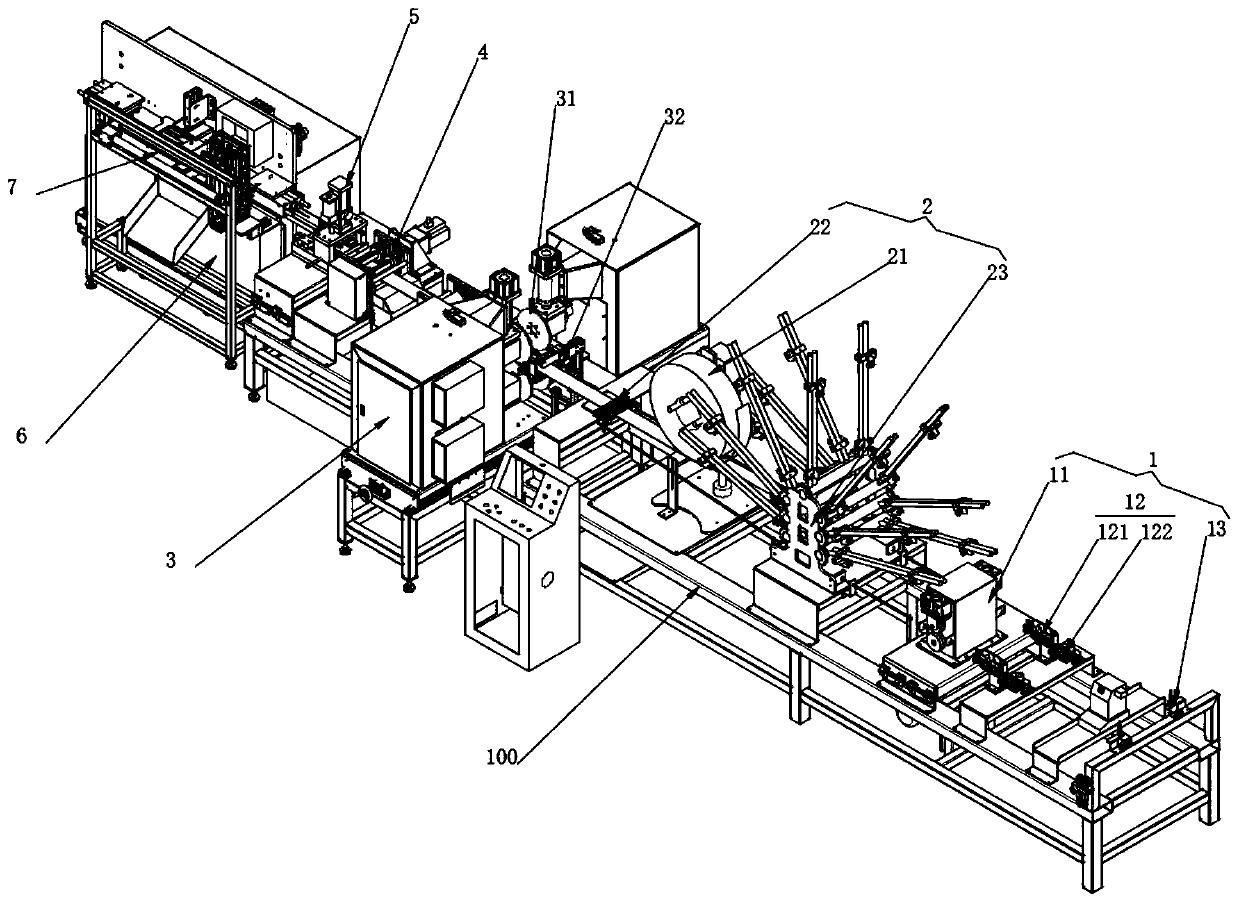

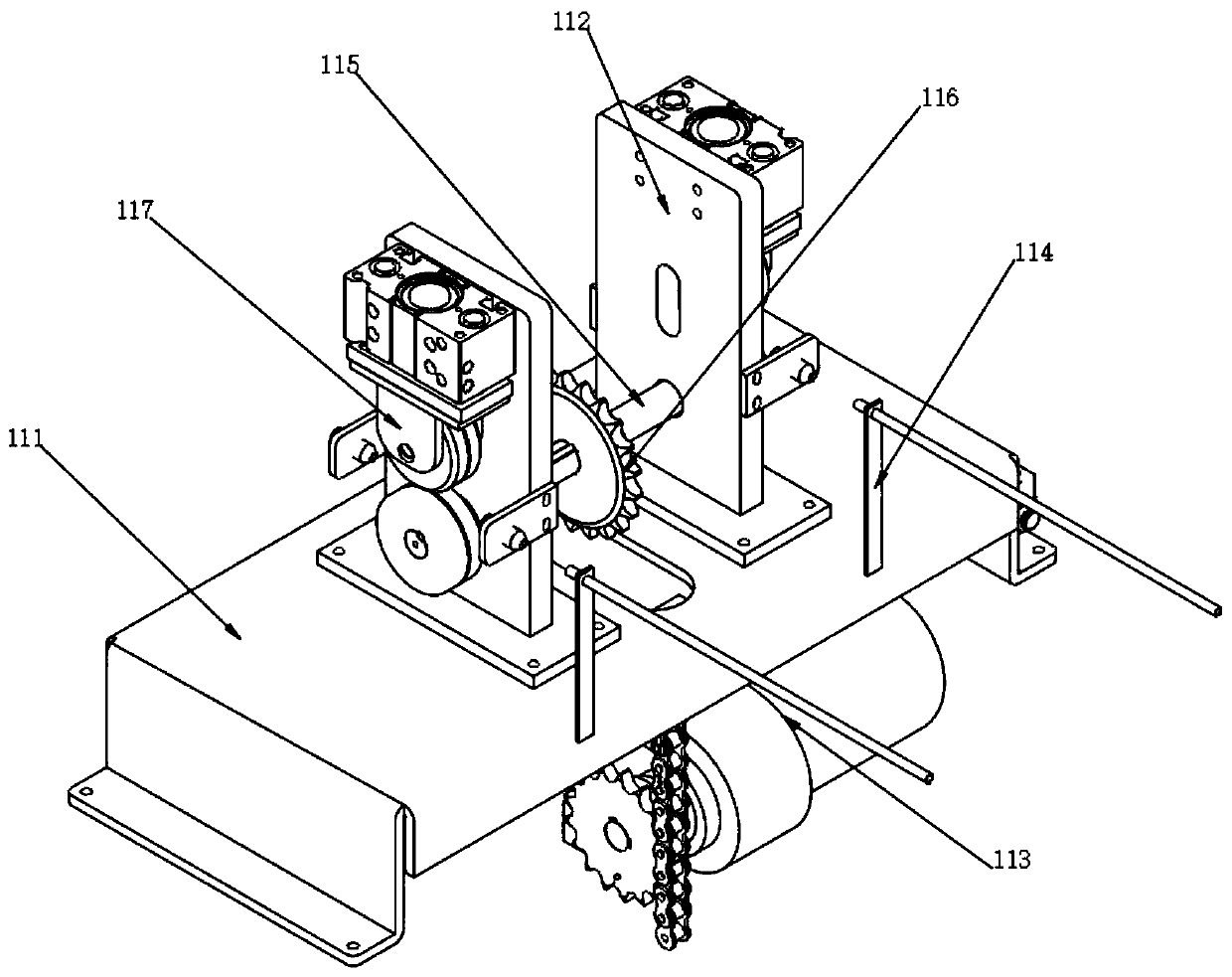

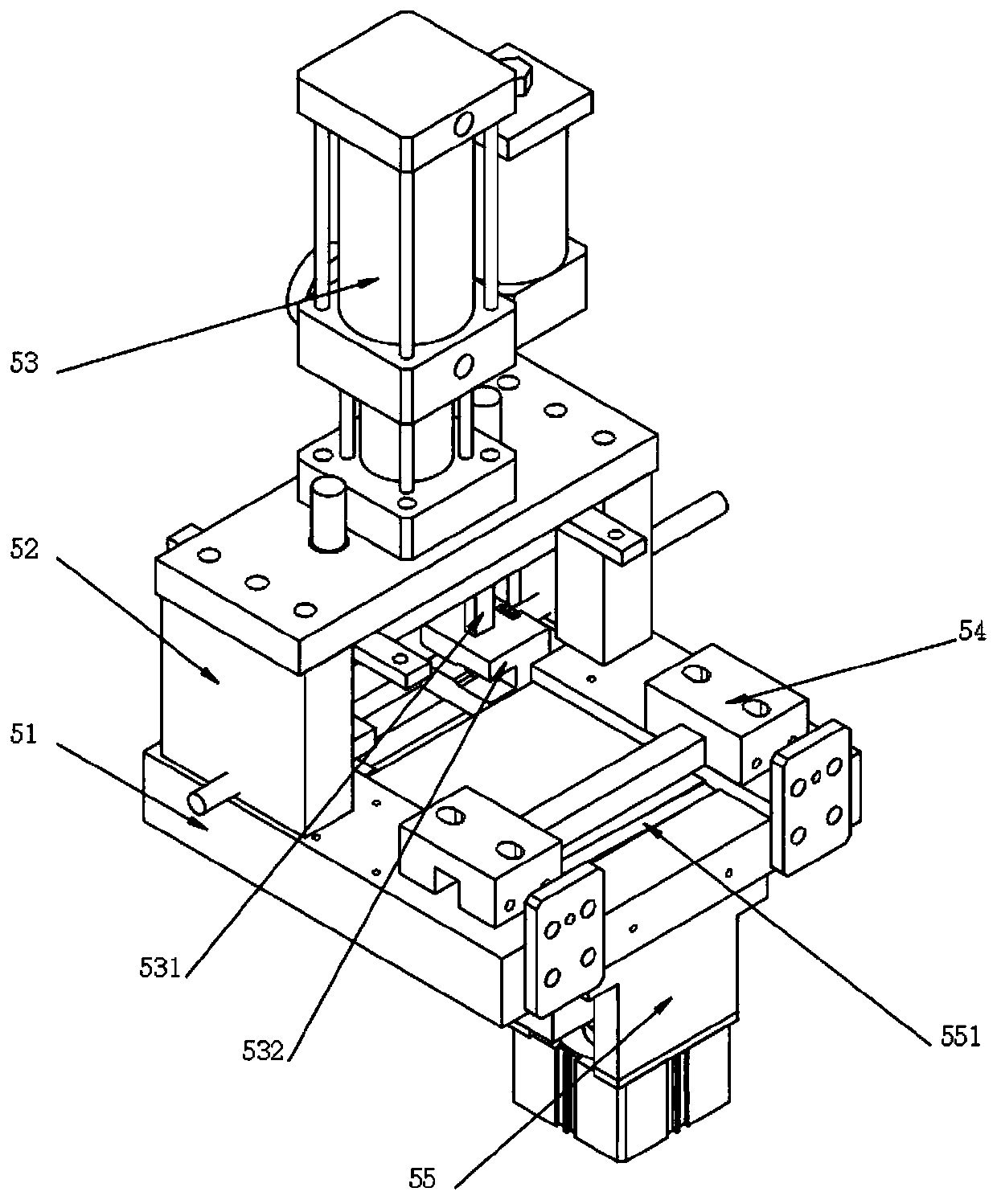

[0028] see Figure 1-4 , the present invention provides a technical solution: a wire automatic forming machine with automatic unloading, including a frame 100, on which a wire feeding assembly 1, a steel mesh feeding assembly 2, a seam welding machine 3, servo drive unit 4, cutting unit 5, bending machine 6 and manipulator unit 7, seam welding machine 3 is used to weld steel mesh and steel wire together; cutting unit 5 includes cutting seat 51, steel wire cutting box 52, steel wire Cut off cylinder 53, steel mesh cutter seat 54 and steel mesh cutter cylinder 55, cutting seat 51 is installed on the end of frame 100, and steel wire cutting box 52 is installed on the upper end face entrance side of cutting seat 51, and steel wire cuts off cylinder 53 and is installed on Above the steel wire cutting box 52, and the output end of the steel wire cutting cylinder 53 is equipped with a steel wire cutter 531 for cutting the steel wire, the steel wire cutter 531 is provided with a steel...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap