Preparation method of safe high-thermal-conductivity floor heating material

A high thermal conductivity and floor heating technology, applied in the field of building materials, can solve the problems of poor safety performance, low heat storage and heating efficiency, etc., and achieve the effects of improved thermal conductivity, reduced waste, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

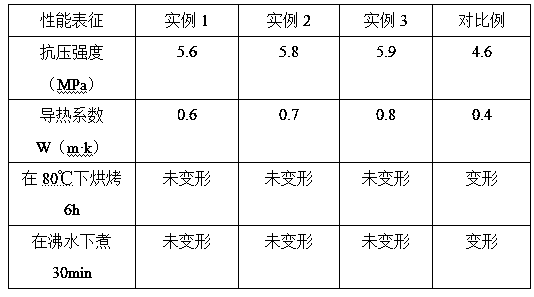

example 1

[0027] Carry out magnetron sputtering coating treatment on carbon fiber to obtain composite carbon fiber; mix composite carbon fiber, liquid silica gel and platinum vulcanizing agent, stir and treat at constant temperature, take it out to obtain precursor fiber, and place precursor fiber in muffle furnace , carry out carbonization treatment, and cool to room temperature to obtain carbonized composite fiber; take kaolin, cordierite, carbonized composite fiber, white carbon black, bauxite, deionized water, kaolin, cordierite, white carbon black, bauxite Stone and deionized water are mixed and ball milled to obtain the mixture. The mixture is dried and cooled to room temperature to obtain the precursor mixture. The precursor mixture is subjected to compression molding to obtain the green body. The green body is placed in the In the Fu furnace, heat preservation and sintering treatment is carried out, and it is cooled to room temperature to obtain a safe and high thermal conductivi...

example 2

[0029] Carry out magnetron sputtering coating treatment on carbon fiber to obtain composite carbon fiber; mix composite carbon fiber, liquid silica gel and platinum vulcanizing agent, stir and treat at constant temperature, take it out to obtain precursor fiber, and place precursor fiber in muffle furnace , carry out carbonization treatment, and cool to room temperature to obtain carbonized composite fiber; take kaolin, cordierite, carbonized composite fiber, white carbon black, bauxite, deionized water, kaolin, cordierite, white carbon black, bauxite Stone and deionized water are mixed and ball milled to obtain the mixture. The mixture is dried and cooled to room temperature to obtain the precursor mixture. The precursor mixture is subjected to compression molding to obtain the green body. The green body is placed in the In the Fu furnace, heat preservation and sintering treatment is carried out, and it is cooled to room temperature to obtain a safe and high thermal conductivi...

example 3

[0031] Carry out magnetron sputtering coating treatment on carbon fiber to obtain composite carbon fiber; mix composite carbon fiber, liquid silica gel and platinum vulcanizing agent, stir and treat at constant temperature, take it out to obtain precursor fiber, and place precursor fiber in muffle furnace , carry out carbonization treatment, and cool to room temperature to obtain carbonized composite fiber; take kaolin, cordierite, carbonized composite fiber, white carbon black, bauxite, deionized water, kaolin, cordierite, white carbon black, bauxite Stone and deionized water are mixed and ball milled to obtain the mixture. The mixture is dried and cooled to room temperature to obtain the precursor mixture. The precursor mixture is subjected to compression molding to obtain the green body. The green body is placed in the In the Fu furnace, heat preservation and sintering treatment is carried out, and it is cooled to room temperature to obtain a safe and high thermal conductivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com