Sterilization monitoring indicating tape without printing ink transfer and residual glue

A technology for indicating tape and ink transfer, applied to inks, adhesives, natural rubber coatings, etc., can solve problems such as temperature resistance deviation, misjudgment by sterilizers, waterproof coatings that are not resistant to high temperature steam, etc., and achieve improved tensile strength and toughness, avoiding the effect of falling off or transferring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The masking paper is beige masking paper provided by Smith Paper, with a grammage of 60g / ㎡, a thickness of 0.12mm, a tensile strength of >42N, an elongation of 17%, and a moisture content of 4.5%. The width of masking paper is 1280mm.

[0019] The toughening agent is natural rubber (Vietnam 3L standard rubber), urea-formaldehyde resin, 120# mineral oil, stearic acid, zinc oxide, diphenylguanidine, and elemental sulfur are respectively 15%, 15%, 60%, and 5% by mass percentage , 2%, 2%, 1% mixture. Dissolve natural rubber in 120# mineral oil and ball mill for 12 hours, then add urea-formaldehyde resin to ball mill for 12 hours, then add stearic acid, zinc oxide, diphenylguanidine and elemental sulfur, and air ball mill for 1 hour. A uniform translucent light yellow toughening agent was obtained.

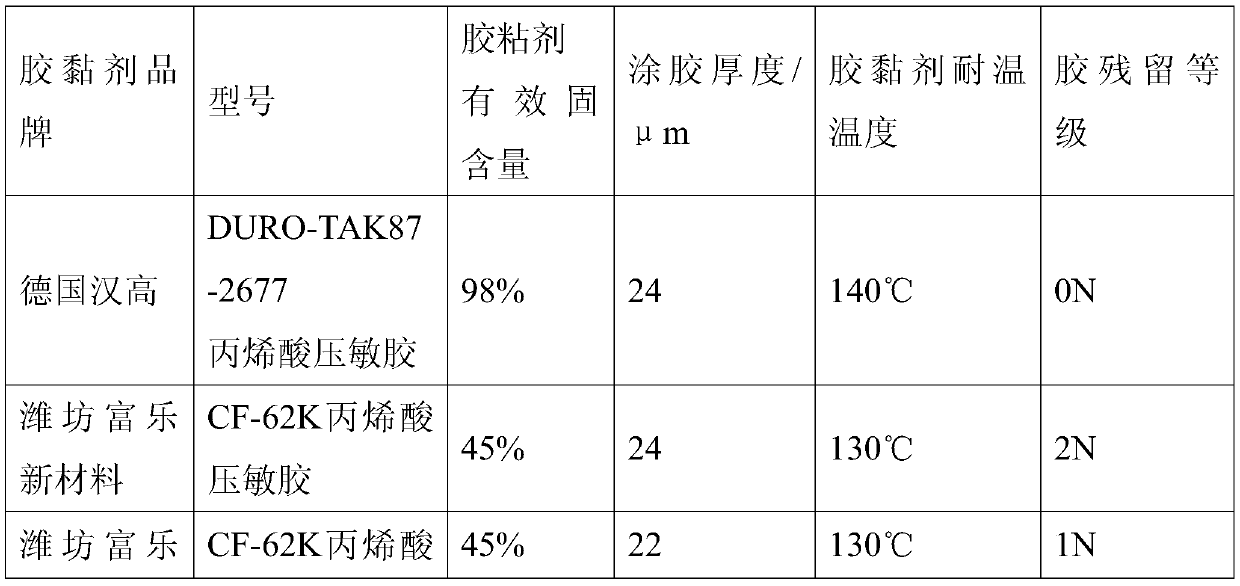

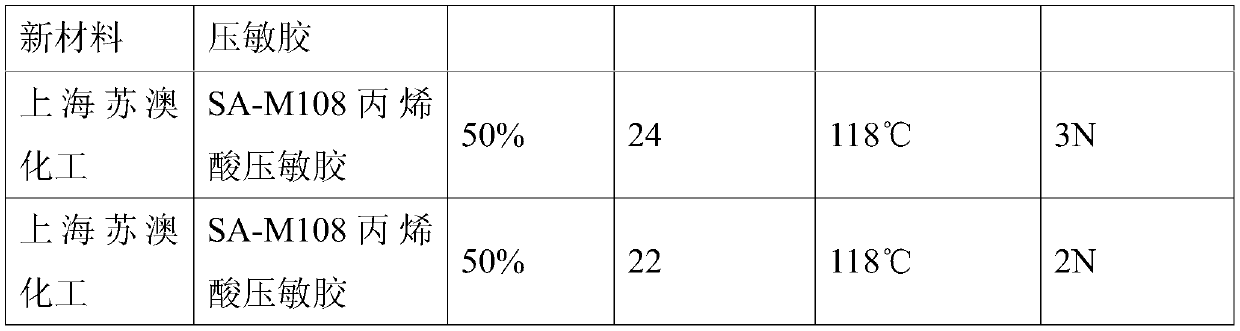

[0020] The adhesive is Henkel / DURO-TAK87-2677 acrylic pressure-sensitive adhesive from Germany, in which the effective solid content of acrylic acid is 98%, and the thickness ...

Embodiment 2

[0032] The masking paper is beige masking paper provided by Smith Paper, with a grammage of 75g / ㎡, a thickness of 0.14mm, a tensile strength of 44N, an elongation of 17%, and a moisture content of 4%. The width of masking paper is 1280mm.

[0033] The toughening agent is natural rubber (3L standard natural rubber imported from Vietnam), urea-formaldehyde resin, 120# mineral oil, stearic acid, zinc oxide, diphenylguanidine, and elemental sulfur are respectively 20%, 15%, 56%, and 5%, 2%, 1%, 1% mixture.

[0034] The adhesive is Henkel / DURO-TAK87-2677 acrylic pressure-sensitive adhesive from Germany, in which the effective solid content of acrylic acid is 98%, and the thickness of the high-temperature-resistant adhesive on the textured paper is 22 μm.

[0035] The preparation of waterproof sealing ink: antimony tin oxide (self-made, preparation method is the same as embodiment one, mass percent is 5%), polymethyl methacrylate (Lucite 2044, 15%), natural rosin (5%), Phenolic re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com