Absorbing agent and preparation method thereof

The technology of a wave absorbing agent and expanded graphite is applied in the field of wave absorbing materials, which can solve the problems of complex preparation process, narrow wave absorption frequency band and low absorption rate of wave absorbing materials, and achieves simple preparation technology, simple preparation method and strong absorption capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a wave absorbing agent and a preparation method thereof, the method comprising the following steps:

[0024] Dissolve 30-70 parts of graphite in 5-10 parts of concentrated sulfuric acid (concentrated sulfuric acid with a mass fraction greater than 70%) to form a concentrated sulfuric acid solution of graphite; then add the concentrated sulfuric acid solution of graphite to 80-120 parts of deionized water, then mechanically stirred in a water bath at 50-60°C for 40-60min, then washed 3-5 times with water, filtered with filter paper with a pore size of 30-50μm, dried at 60-80°C for 10-12h, and then the obtained Graphite is placed in a muffle furnace that has been heated to 800-1000 ° C for 5-10 minutes, and then cooled to prepare expanded graphite;

[0025] Stir and mix 5-8 parts of ammonia water and 10-20 parts of ethanolamine evenly, then add 200-300 parts of soluble iron salt (one or more of ferric chloride, ferric nitrate and ferric sulfate), an...

Embodiment 1

[0028] Dissolve 50 parts of graphite in 8 parts of 98% concentrated sulfuric acid to form a concentrated sulfuric acid solution of graphite; then add the concentrated sulfuric acid solution of graphite to 90 parts of deionized water, and then mechanically stir in a water bath at 55°C for 50 minutes , followed by washing with water for 4 times, then filtering and drying, and then putting the obtained graphite into a muffle furnace heated to 900°C for 8 minutes, and then cooling to prepare expanded graphite;

[0029] Stir and mix 6 parts of ammonia water and 15 parts of ethanolamine, then add 220 parts of ferric chloride, stir and mix evenly, and then react in a reactor at 220°C for 7 hours to obtain a mixed solution, which is poured into In the reaction vessel beaker;

[0030] Add 16 parts of expanded graphite to 45 parts of the mixed solution, adjust the pH to 10.5-11.5, mechanically stir in an oil bath at 100°C for 10 hours, absorb the magnetic substance to the bottom of the ...

Embodiment 2

[0032] Dissolve 60 parts of graphite in 9 parts of 98% concentrated sulfuric acid to form a concentrated sulfuric acid solution of graphite; then add the concentrated sulfuric acid solution of graphite to 100 parts of deionized water, and then mechanically stir in a water bath at 60°C for 50 minutes , followed by washing with water three times, filtering and drying, and then putting the obtained graphite into a muffle furnace heated to 950°C for 6 minutes, and then cooling to prepare expanded graphite;

[0033] Stir and mix 6 parts of ammonia water and 12 parts of ethanolamine, then add 260 parts of ferric nitrate, stir and mix evenly, and then react in a reactor at 250°C for 8 hours to obtain a mixed solution, which is poured into In the reaction vessel beaker;

[0034] Add 18 parts of expanded graphite to 46 parts of the mixed solution, adjust the pH to 10.5-11.5, mechanically stir in an oil bath at 110°C for 11 hours, absorb the magnetic substance to the bottom of the beake...

PUM

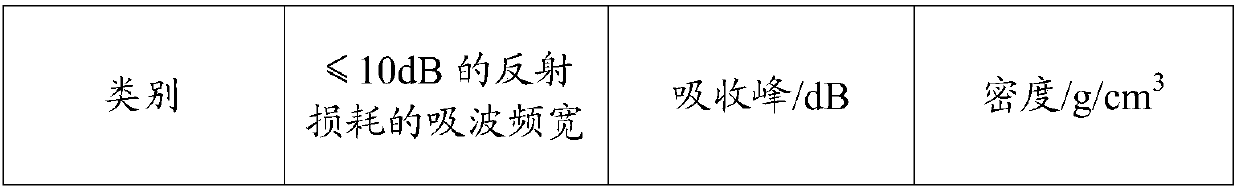

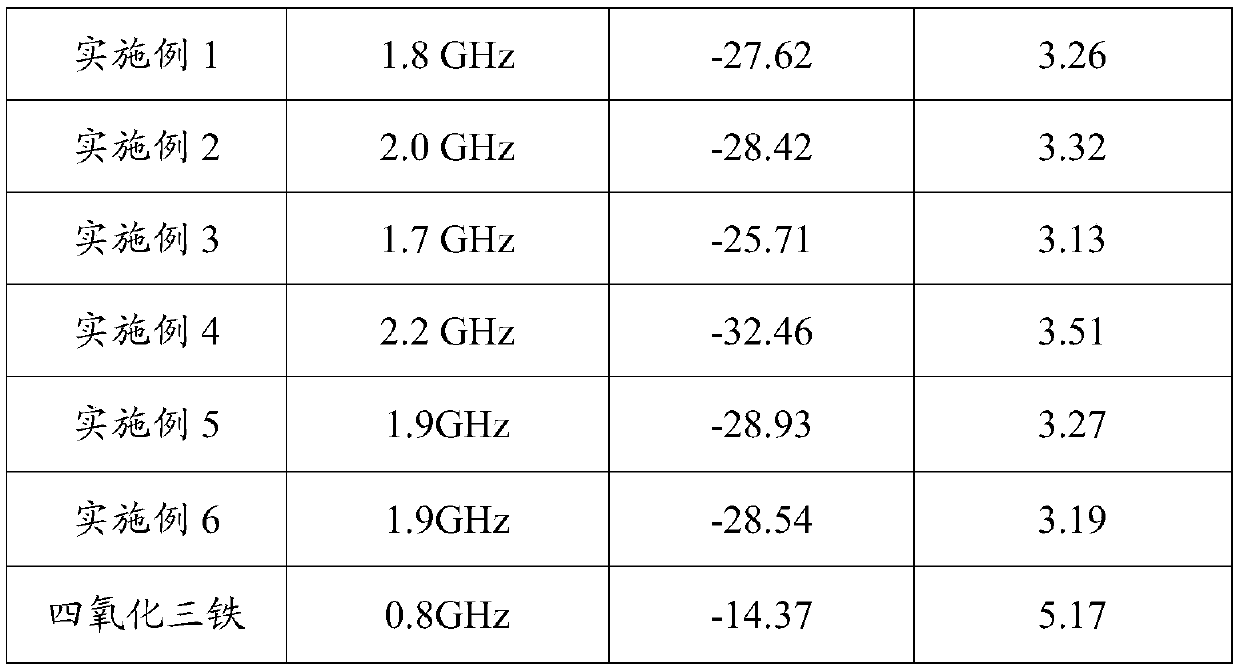

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Return loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com