Method for preparing calcium alginate-fat acellular matrix microcarrier by applying micro-fluidic chip

A technology of acellular matrix and microfluidic chip, applied in the field of tissue engineering bio-scaffold microcarriers, can solve the problems of difficult stem cell culture, difficult preparation, poor cell affinity, etc., and achieve the effect of facilitating cell growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

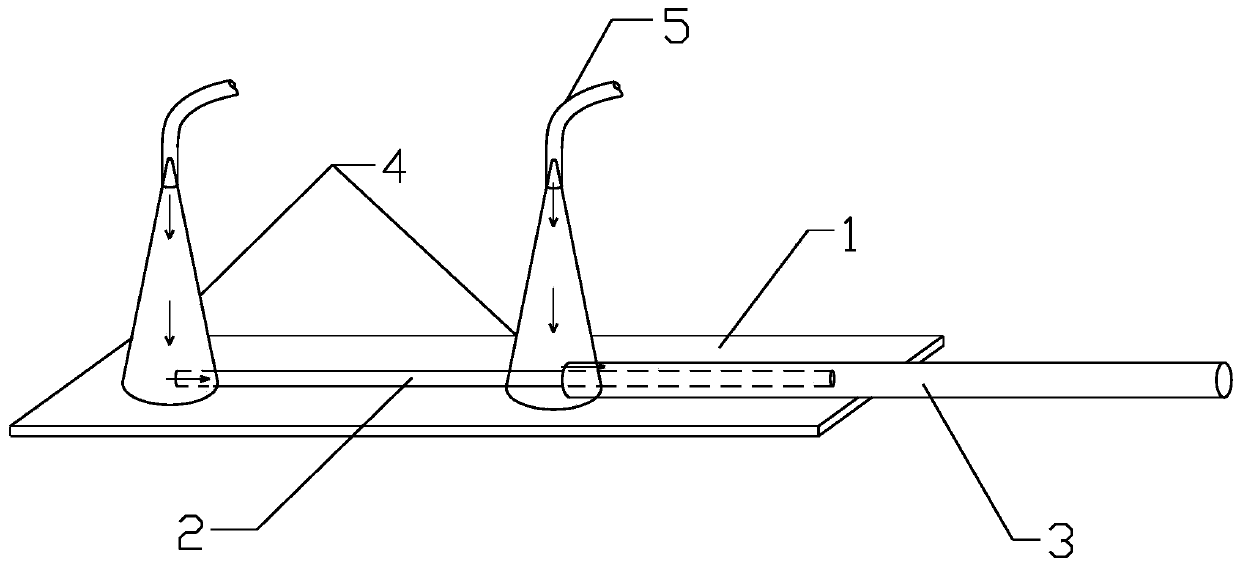

[0032] The capillary microfluidic chip in the following examples is prepared according to the following method: nest glass capillaries with an inner diameter of 100 um and an inner diameter of 500 um for about 3 cm, and then glue the glass slide 1 with epoxy glue, and fix the inner layer Both ends of the capillary 2 and the nested end of the outer capillary 3 and the inner capillary 2 are placed on the slide 1, the non-nested end of the outer capillary 3 protrudes from the slide 1, and the inner capillary 2 is not nested end and the nested end of the outer capillary 3 and the inner capillary 2 respectively buckle the tip 4 of the 10ul sampling gun, and the bottom edge of the tip 4 of the sampling gun is sealed and bonded to the glass slide 1 by epoxy glue, and after connection, the The undercut areas of the tip 4 of the two sampling guns respectively fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com