Packaging structure of silicon photonic optical module and packaging method thereof

A packaging structure and silicon photonics technology, which is applied to the assembly of printed circuits with electrical components, printed circuits connected with non-printed electrical components, semiconductor devices, etc., can solve the problem of affecting signal integrity, unfavorable control of gold wire bonding length, Increase production and packaging costs and other issues to achieve the effect of enhancing the ability to resist electromagnetic interference, reducing the length of gold wire bonding, and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

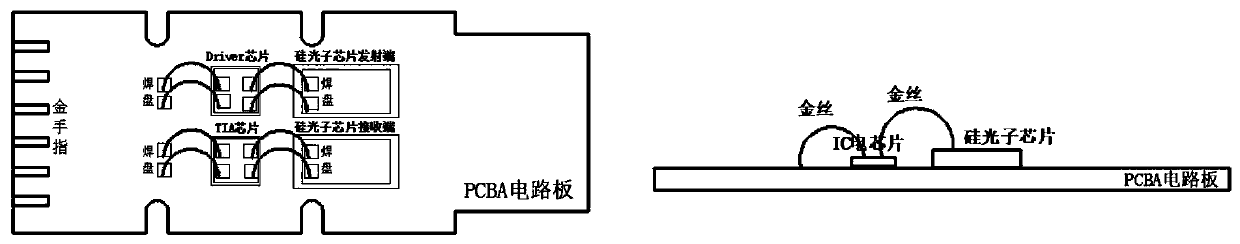

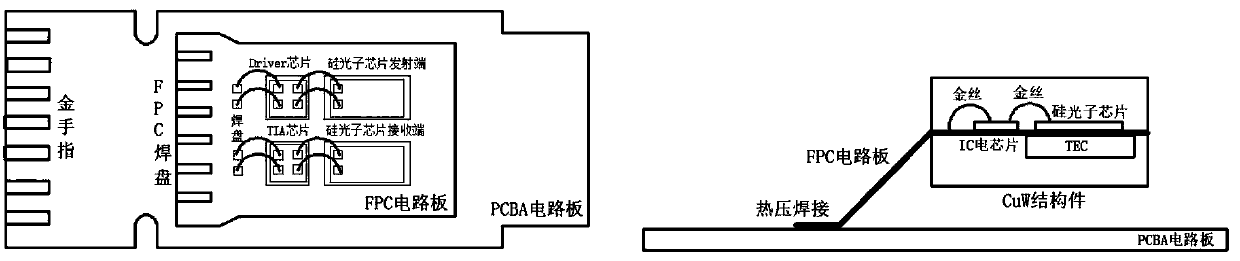

[0039] A packaging structure of a silicon photonic optical module, including: a PCBA circuit board, a CuW base, a CuW cover, a silicon photonic chip emitting unit and a silicon photonic chip receiving unit, a driver chip, a transimpedance amplifier chip, and a TEC;

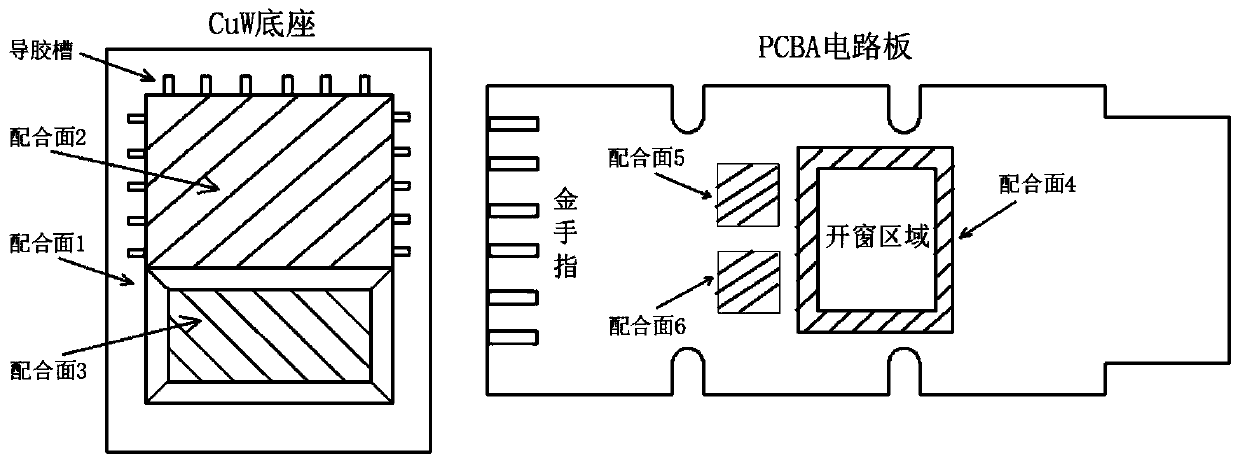

[0040] The PCBA circuit board is provided with a window area; the edge of the lower surface of the window area is the fourth mating surface; the fifth mating surface and the sixth mating surface on the PCBA circuit board;

[0041] The edge of the upper surface of the CuW base is the first mating surface; the CuW base is also provided with a second mating surface and a third mating surface;

[0042] The first mating su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com