Solid oxide fuel cell composite sealant and application thereof

A solid oxide and composite sealing technology, which is applied to fuel cell parts, sealing/supporting devices, etc., can solve problems such as difficult to achieve pressurized sealing, and achieve the effect of good sealing and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

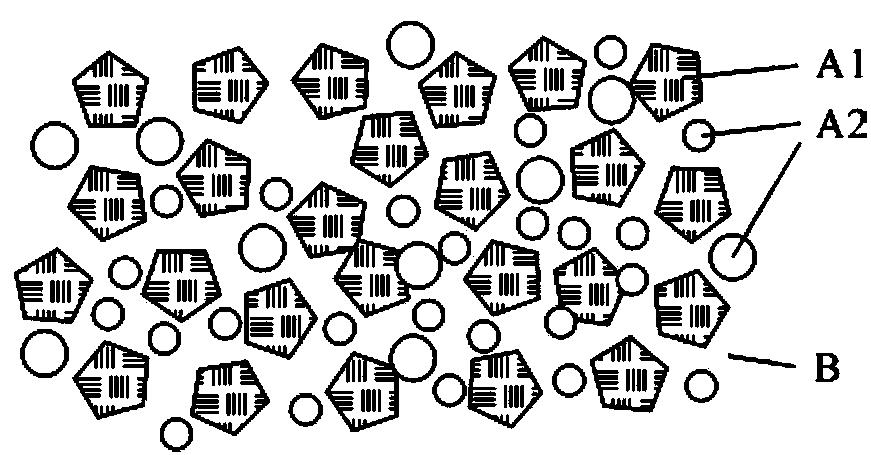

[0022] Composite sealants for tubular solid oxide fuel cells, including solid glass components (such as figure 1 shown in A1 and A2) and liquid glass components (such as figure 1 shown in B).

[0023] In this embodiment, the solid glass component A1 is SrO-Al 2 o 3 -SiO 2 glass powder. A2 is SrO-K 2 O-Al 2 o 3 -SiO 2 glass powder. The glass is prepared by the traditional melting method. The oxide raw materials mixed in proportion are melted at 1300-1500°C and then quenched to obtain glass frit, which is dried and crushed to obtain glass powder. Liquid glass component B is an aqueous glass solution containing Sr and K, which is obtained by hydrolyzing silicate glass in an alkaline solution containing Sr and K under heating and pressure.

[0024] In this embodiment, the weight ratio of the solid glass component is 80%, and the weight ratio of the liquid glass component is 20%. The solid glass component and the liquid glass component are mixed and evenly coated on the...

Embodiment 2

[0027] The difference from Example 1 is that the solid glass component of the composite sealant is BaO-Al 2 o 3 -SiO 2 Glass powder, the liquid glass component is an aqueous solution of silicate glass containing Na and Ba. In this embodiment, the weight ratio of the solid glass component is 50%, and the weight ratio of the liquid glass component is 50%. After the solid glass component and the liquid glass component are mixed, they are uniformly distributed on the parts to be sealed, and after being fully dried, heat treatment is carried out at 600°C.

Embodiment 3

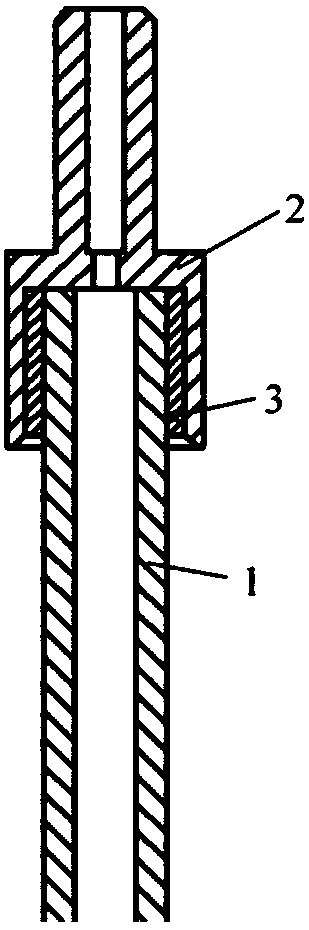

[0029] The difference from Example 2 is that the solid glass component of the composite sealant is BaO-Al 2 o 3 -SiO 2 A mixture of glass powder and fibers. The mixture of the glass powder and fiber is dispersed in the organic solution of PVB, and coated between the solid oxide fuel cell unit 1 and the metal terminal 2 that need to be sealed (such as image 3 shown), dry and pre-fire at 800°C to obtain a porous glass skeleton, then fill the pores of the glass skeleton with liquid glass components to form a glass sealing layer 3, and use it after drying.

[0030] Figure 4 It is the performance of the tubular battery sealed by the composite sealant of the present invention. Compared with batteries sealed with traditional silicate adhesive (high temperature glue), due to the improved sealing performance, the open circuit potential and power density of the battery are significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com