One-phase short-circuit fault-tolerant direct torque control method for five-phase permanent magnet motor

A direct torque control, permanent magnet motor technology, applied in motor control, motor generator control, AC motor control, etc., to increase the complexity, suppress torque ripple, and improve torque control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to more simply and clearly illustrate the characteristics and beneficial effects of the fault-tolerant direct torque control strategy of the five-phase permanent magnet motor of the present invention, a specific five-phase permanent magnet motor will be described in detail and completely below.

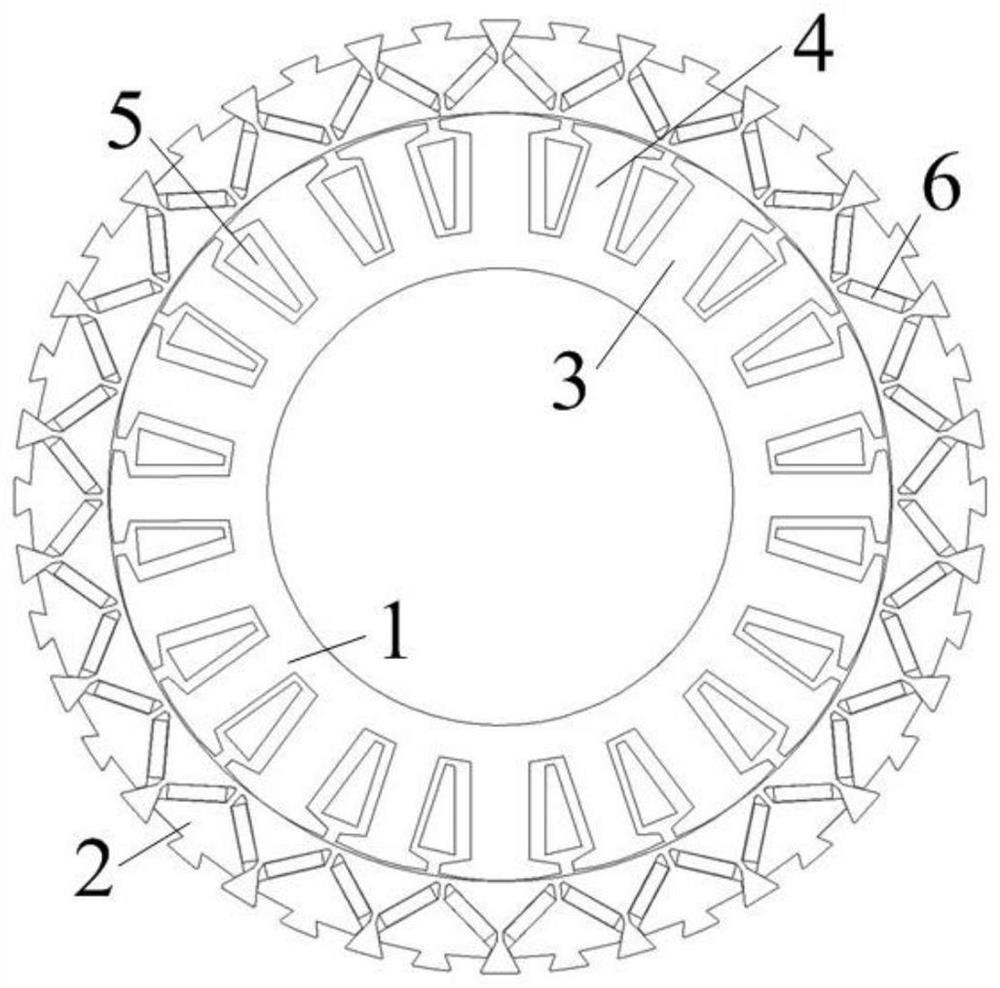

[0041] like figure 1 As shown, the structural schematic diagram of the five-phase permanent magnet motor of the embodiment of the present invention adopts the outer rotor structure of 20 slots / 22 poles and the single-layer concentrated winding mode; the addition of fault-tolerant teeth makes the magnetic and thermal coupling between the windings of each phase almost zero. When one phase of the motor fails, the normal phase will not be affected by the faulty phase, which has strong fault tolerance performance. In addition, the addition of fault-tolerant teeth reduces the coupling between the non-faulty phase and the faulty phase of the motor under fault conditions. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com