Negative electrode active material for secondary battery and preparation method thereof

A negative electrode active material, secondary battery technology, applied in the direction of active material electrodes, electrode manufacturing, battery electrodes, etc., can solve the problems of difficulty in practical application, life deterioration, etc., to suppress cracks and/or cracks, improve life and The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0052] Hereinafter, the present invention will be described in more detail by way of specific examples, but the present invention is not limited to these examples.

Embodiment

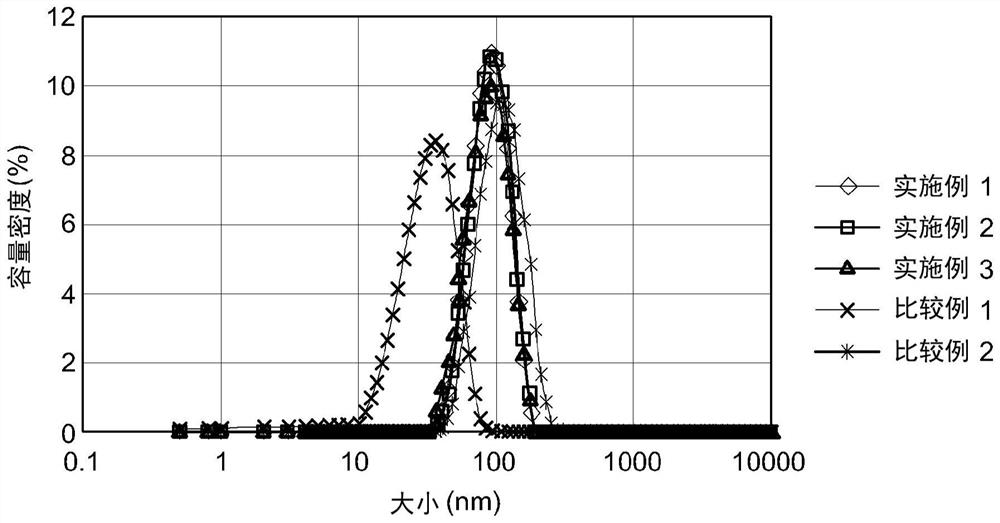

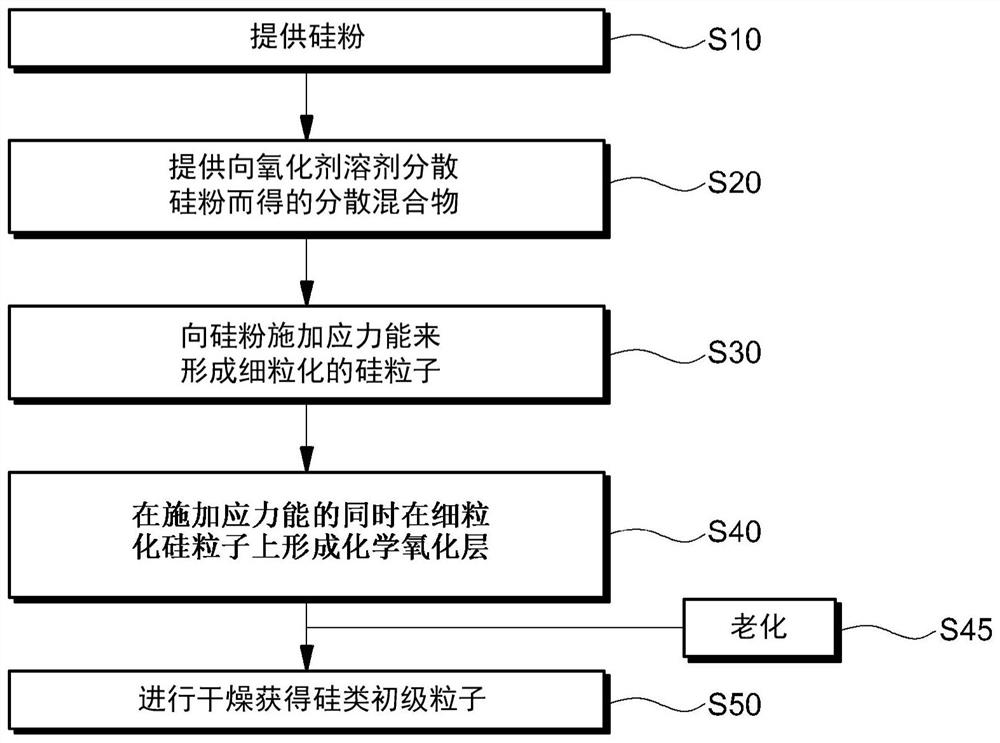

[0054] A dispersion mixture was prepared by dispersing 2 kg of conventional polycrystalline silicon powder having an average diameter of about 5 μm in 10 kg of an oxidizing agent solvent of 100% ethanol. The silicon-based primary particles of Examples and Comparative Examples were prepared by performing a bead milling and pulverizing step in which stress can be controlled under the conditions in Table 1 below. Table 2 below shows the sphericity and particle size distribution of the prepared particles. The silicon purity of the analyzed silicon-based primary particles was 99% or more. The above-mentioned preparation method is an example, and the above-mentioned silicon particles may be prepared by other grinding processes or by blasting the bulk silicon material (eg, silicon wire and silicon wafer).

[0055] Table 1

[0056]

[0057] Table 2

[0058]

[0059] Referring to Table 1 and Table 2, it can be seen that, as in Examples 1 to 3, when the silicon powder is wet pul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com