ZnFe2O4 hollow sphere-RGO composite material and preparation method thereof

A composite material, znfe2o4 technology, applied in the field of ZnFe2O4 hollow sphere-RGO composite material and preparation, can solve the problems of low concentration gas detection performance to be improved, final product cannot be acetone gas detection, complex preparation method, etc., to improve electron mobility , good gas-sensing properties, simple and safe preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

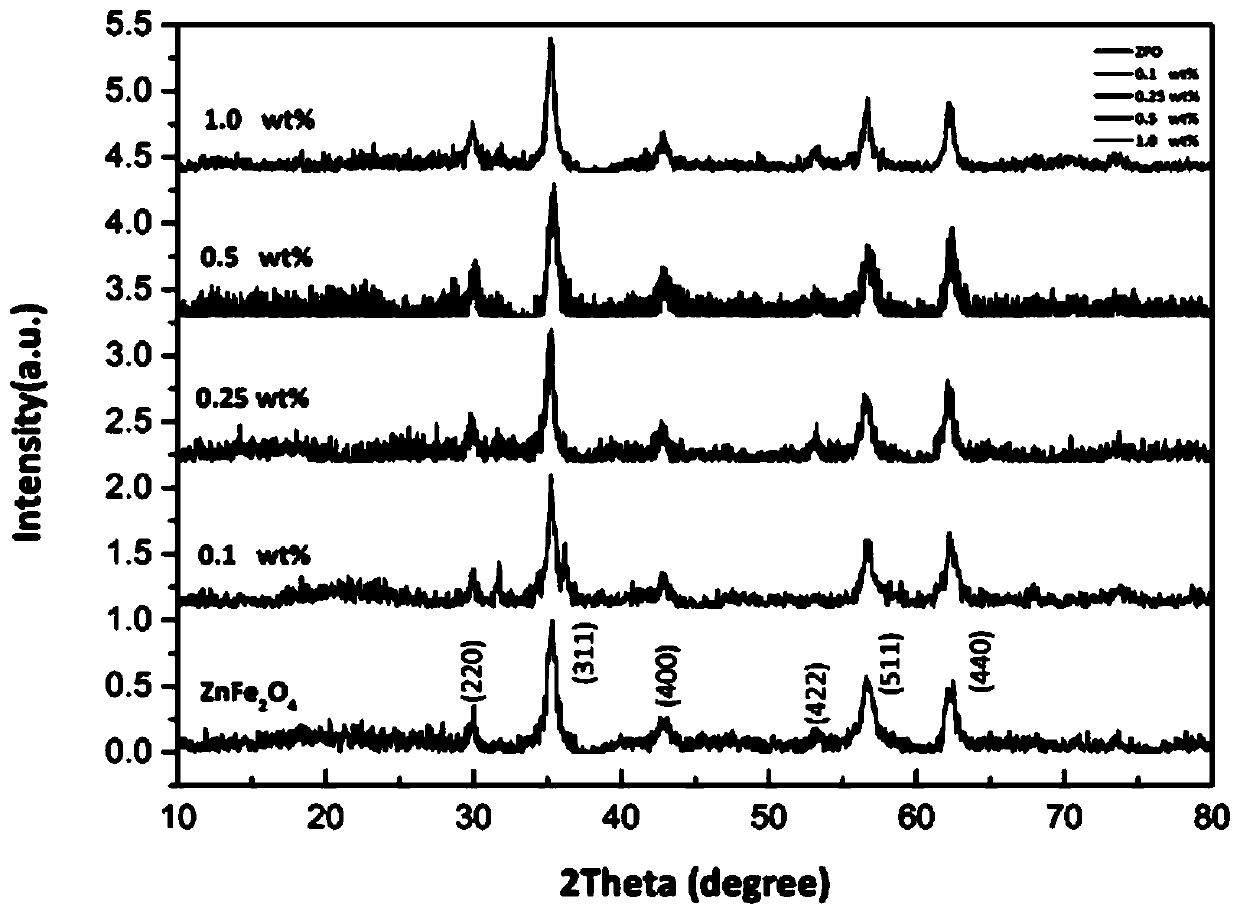

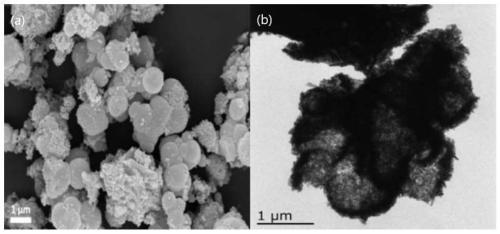

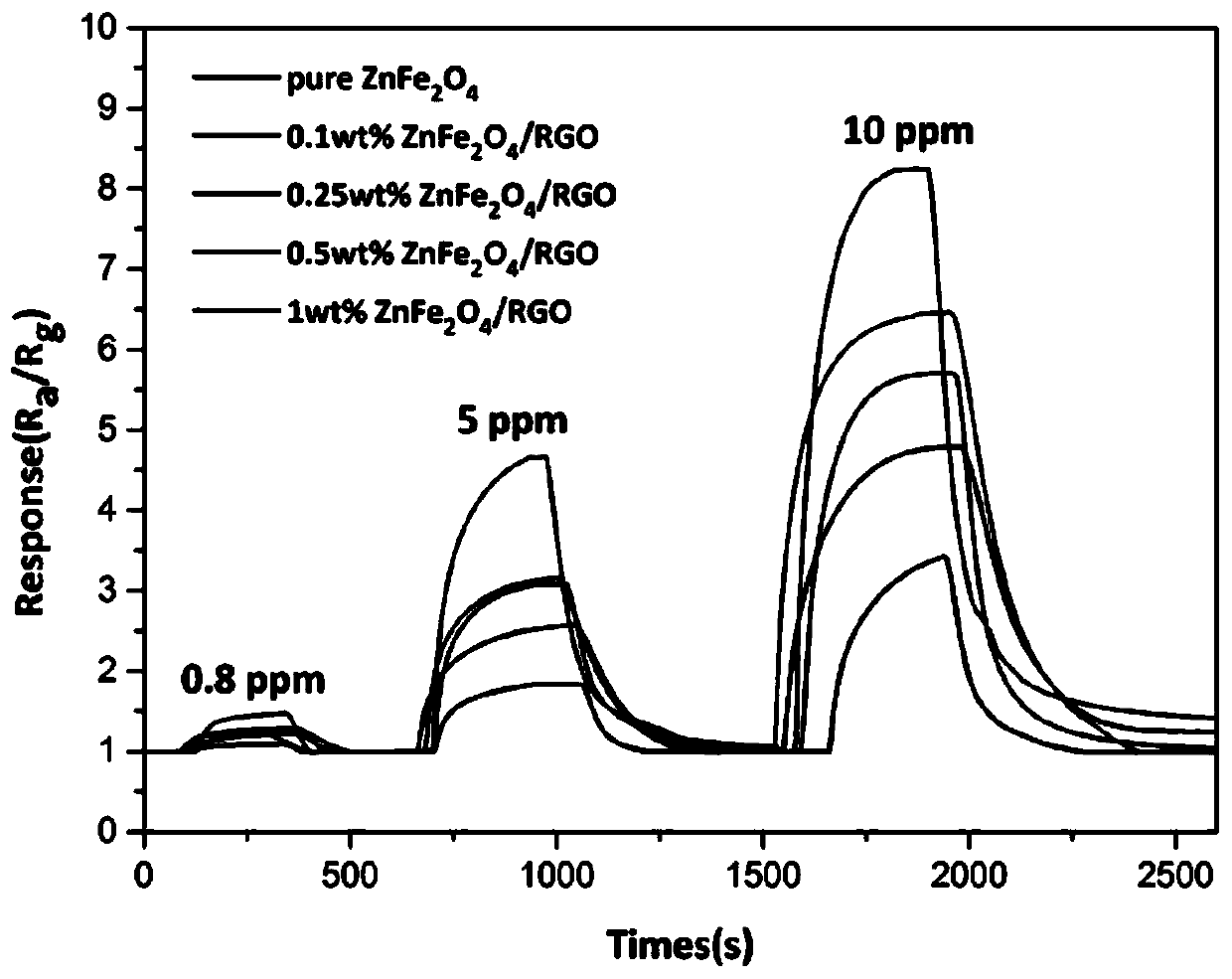

Embodiment 1

[0038] At room temperature, 50ml (0.5mg / ml) of the solution was ultrasonically treated for 2 hours, and stirred with a glass rod for 1 minute every 30 minutes to obtain a graphene oxide dispersion with a good dispersion effect. Mix 8ml of glycerol and 30ml of isopropanol, and stir magnetically to obtain a homogeneous solution. 0.5mmol Zn(CH 3 COO) 2 2H 2 O, 1mmol Fe(NO 3 ) 3 9H 2 O and 0.242ml GO dispersion liquid were successively added into the mixed solvent while stirring, and a uniform solution was obtained after stirring for a certain period of time. Then transfer it to a 50ml polytetrafluoroethylene-lined stainless steel autoclave, seal it, and keep it at 180°C for 12h. After the reaction is over, cool it down to room temperature naturally, centrifuge, wash, and dry the product at 80°C for 12h , to obtain the precursor material. Finally, the obtained precursor material was subjected to high-temperature inert atmosphere heat treatment at a temperature of 400°C, hel...

Embodiment 2

[0040] At room temperature, 50ml (0.5mg / ml) of the solution was ultrasonically treated for 2 hours, and stirred with a glass rod for 1 minute every 30 minutes to obtain a graphene oxide dispersion with a good dispersion effect. Mix 8ml of glycerol and 30ml of isopropanol, and stir magnetically to obtain a homogeneous solution. 0.5mmol Zn(CH 3 COO) 2 2H 2 O, 1mmol Fe(NO 3 ) 3 9H 2 O and 0.602ml GO dispersion liquid were successively added to the mixed solvent while stirring, and a uniform solution was obtained after stirring for a certain period of time. Then transfer it to a 50ml polytetrafluoroethylene-lined stainless steel autoclave, seal it, and keep it at 180°C for 12h. After the reaction is over, cool it down to room temperature naturally, centrifuge, wash, and dry the product at 80°C for 12h , to obtain the precursor material. Finally, the obtained precursor material was subjected to high-temperature inert atmosphere heat treatment at a temperature of 400°C, held ...

Embodiment 3

[0042] At room temperature, 50ml (0.5mg / ml) of the solution was ultrasonically treated for 2 hours, and stirred with a glass rod for 1 minute every 30 minutes to obtain a graphene oxide dispersion with a good dispersion effect. Mix 8ml of glycerol and 30ml of isopropanol, and stir magnetically to obtain a homogeneous solution. 0.5mmol Zn(CH 3 COO) 2 2H 2 O, 1mmol Fe(NO 3 ) 3 9H 2 O and 1.205ml GO dispersion liquid were successively added to the mixed solvent while stirring, and a uniform solution was obtained after stirring for a certain period of time. Then transfer it to a 50ml polytetrafluoroethylene-lined stainless steel autoclave, seal it, and keep it at 180°C for 12h. After the reaction is over, cool it down to room temperature naturally, centrifuge, wash, and dry the product at 80°C for 12h , to obtain the precursor material. Finally, the obtained precursor material was subjected to high-temperature inert atmosphere heat treatment at a temperature of 400°C, held ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com