Sewage treatment flocculating agent and production method thereof

A sewage treatment and flocculant technology, applied in water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, chemical instruments and methods, etc., can solve the problem of poor removal of heavy metal ions and limited flocculation capacity of flocculants, etc. problems, to achieve the effect of easy handling, low cost, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

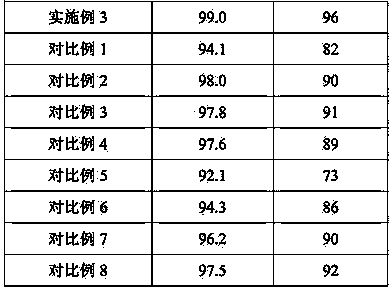

Examples

Embodiment 1

[0028] A sewage treatment flocculant in parts by weight, comprising the following raw materials: 20 parts of 10-30 mesh zeolite powder, 50 parts of celery leaf powder, 6 parts of dendrobium leaf powder, 20 parts of carboxymethyl starch, 1 part of 8-hydroxyquinoline 7.5 parts of chitosan, 6 parts of modified dissolving pulp, 3 parts of tung oil anhydride, 3 parts of modified bio-oxidized oil.

[0029] The concentration of the modified dissolving pulp is 20%. The modified dissolving pulp is obtained by adding cellulase with a mass of 1% of the dissolving pulp to the dissolving pulp and hydrolyzing it at 40° C. for 30 hours. The dendrobium leaf powder is obtained after the production of Dendrobium candidum, the thicker leaves of the mesophyll in the residual discarded dendrobium leaves are crushed to 80 mesh, and 100g of the dendrobium leaf powder is soaked in 200mL of 0.2mol / L sodium hydroxide at 40 degrees Celsius, 0.1mol / L Add 0.2 mol / L hydrochloric acid to neutralize after 2...

Embodiment 2

[0032] A sewage treatment flocculant in parts by weight, comprising the following raw materials: 10 parts of 10-30 mesh zeolite powder, 65 parts of celery leaf powder, 3 parts of dendrobium leaf powder, 25 parts of carboxymethyl starch, 0.1 parts of 8-hydroxyquinoline 12 parts of chitosan, 4 parts of modified dissolving pulp, 4 parts of tung oil anhydride, 2 parts of modified bio-oxidized oil.

[0033] The concentration of the modified dissolving pulp is 20%. The modified dissolving pulp is obtained by adding cellulase with a mass of 1% of the dissolving pulp to the dissolving pulp and hydrolyzing it at 40° C. for 30 hours. The dendrobium leaf powder is obtained after the production of Dendrobium candidum, the thicker leaves of the mesophyll in the residual discarded dendrobium leaves are crushed to 80 mesh, and 100g of the dendrobium leaf powder is soaked in 200mL of 0.2mol / L sodium hydroxide at 40 degrees Celsius, 0.1mol / L Add 0.2 mol / L hydrochloric acid to neutralize after...

Embodiment 3

[0036] A sewage treatment flocculant in parts by weight, comprising the following raw materials: 35 parts of 10-30 mesh zeolite powder, 35 parts of celery leaf powder, 10 parts of dendrobium leaf powder, 15 parts of carboxymethyl starch, 1.5 parts of 8-hydroxyquinoline 3 parts of chitosan, 8 parts of modified dissolving pulp, 2 parts of tung oil anhydride, 4 parts of modified bio-oxidized oil.

[0037] The concentration of the modified dissolving pulp is 20%. The modified dissolving pulp is obtained by adding cellulase with a mass of 1% of the dissolving pulp to the dissolving pulp and hydrolyzing it at 40° C. for 30 hours. The dendrobium leaf powder is obtained after the production of Dendrobium candidum, the thicker leaves of the mesophyll in the residual discarded dendrobium leaves are crushed to 80 mesh, and 100g of the dendrobium leaf powder is soaked in 200mL of 0.2mol / L sodium hydroxide at 40 degrees Celsius, 0.1mol / L Add 0.2 mol / L hydrochloric acid to neutralize after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com