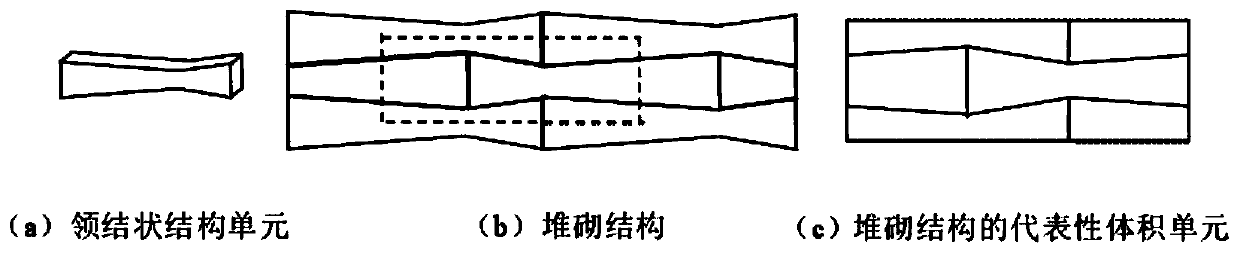

High-strength high-tenacity graphene-enhanced copper-based composite material and biomimetic preparation method for nacreous layer thereof

A copper-based composite material, high-strength and high-toughness technology, applied in the field of metal matrix composite materials, can solve the problem of lack of new cross-scale bionic ideas and new methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In order to improve the strength and toughness matching of copper-based composite materials, and take into account electrical conductivity and wear resistance, the invention provides a graphene-reinforced copper-based composite material with a nacre "brick-mud-bridge" structure bionic and its preparation method , its composition is characterized in that it contains the following components:

[0038] Cr: 0.3w.t.%;

[0039] Fe: 0.05w.t.%;

[0040] Mg: 0.05w.t.%;

[0041] Graphene 1vol%;

[0042] The balance is Cu, and the total impurity content is less than 0.2%.

[0043] In this embodiment, a nacre "brick-mud-bridge" structure bionic graphene-reinforced copper-based composite material and a nacre bionic preparation method thereof, the preparation includes the following steps:

[0044] (1) Spray powder making: first add Fe to the copper melt, then add pure Mg, and finally add pure Cr, and the metal melt mixed with copper, Fe, Mg and Cr is made into powder by gas atomi...

Embodiment 2

[0054] The difference from Example 1 is that in this example, a high-strength and high-toughness graphene-reinforced copper-based composite material and a nacre bionic preparation method thereof include the following components and proportions:

[0055] Cr: 0.6w.t.%;

[0056] Fe: 0.085w.t.%;

[0057] Mg: 0.085w.t.%;

[0058] Graphene 2.5vol%;

[0059] The balance is Cu;

[0060] In this embodiment, the total content of the Fe and Mg elements is less than 0.12%, and the atomic ratio of the two is 2:1;

[0061] In this embodiment, the total impurity content is less than 0.1%.

[0062] In the present embodiment, the total content of Fe and Mg elements added in step (1) is lower than 0.12%, and the atomic ratio of the two is 2:1, and the total content of impurities is less than 0.1%, so as to be similar to that of Example 1. Ratio, if the total content of Fe and Mg elements is higher than 0.12%, the electrical conductivity of the material will be lower than 75% IACS; both Fe ...

Embodiment 3

[0065] Embodiment 3 differs from Embodiment 1 and Embodiment 2 in that:

[0066] A high-strength and high-toughness graphene-reinforced copper-based composite material and a nacre bionic preparation method thereof, comprising the following components and proportions:

[0067] Cr: 0.5w.t.%;

[0068] Fe: 0.07w.t.%;

[0069] Mg: 0.07w.t.%;

[0070] Graphene 2.5vol%;

[0071] The balance is Cu;

[0072] In this embodiment, the total content of the Fe and Mg elements is less than 0.12%, and the atomic ratio of the two is 2:1;

[0073] In this embodiment, the total content of impurities is less than 0.2%;

[0074] In this embodiment, the sintering temperature in step (7) is 700°C;

[0075]In this embodiment, the total content of Fe and Mg elements added in step (1) is lower than 0.12%, and the atomic ratio of the two is 2:1, and the total content of impurities is less than 0.2%, so that the Cu-Cr During the production process of the alloy powder, the quality of the Cu-Cr allo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com