LED epitaxial structure and preparation method thereof, and LED chip

An epitaxial structure, N-type technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of low hole and electron recombination rate, carrier imbalance, limiting the improvement of LED luminous efficiency, etc., to achieve improved recombination efficiency, increase the effective area, and improve the effect of LED luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

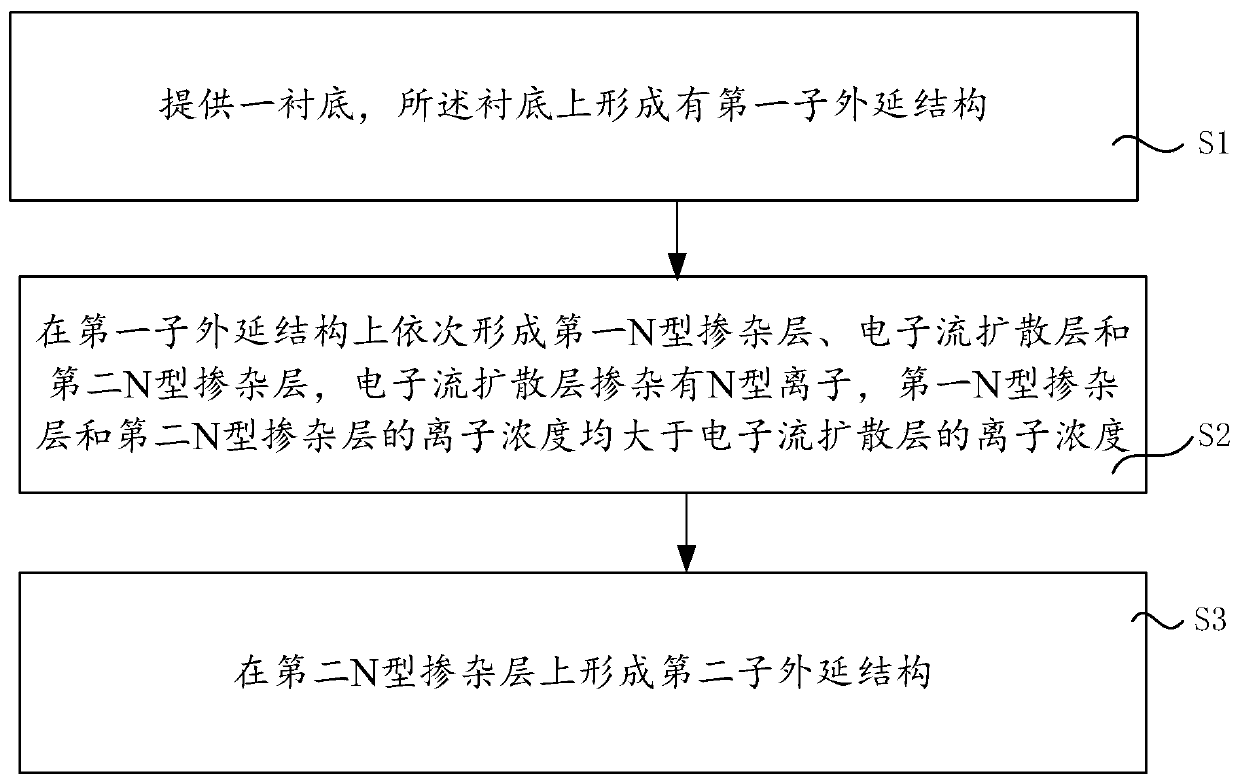

[0040] image 3 It is a schematic flow chart of the method for preparing the LED epitaxial structure in this embodiment. Such as image 3 As shown, this embodiment also provides a method for preparing an LED epitaxial structure, comprising the following steps:

[0041] Step S1: providing a substrate on which a first sub-epitaxial structure is formed;

[0042] Step S2: sequentially forming a first N-type doped layer, an electron flow diffusion layer, and a second N-type doped layer on the first sub-epitaxial structure to form an N-type doped structure, and the electron flow diffusion layer is doped with Doped with N-type ions, the concentration of ions doped in the first N-type doped layer and the second N-type doped layer is greater than the concentration of N-type ions doped in the electron current diffusion layer; and

[0043] Step S3: forming a second sub-epitaxial structure on the second N-type doped layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com