A kind of carbon quantum dot modified ternary cathode material and preparation method thereof

A positive electrode material, carbon quantum dot technology, applied in the direction of electrical components, battery electrodes, structural parts, etc., can solve the problems of affecting the specific capacity of the material, high production cost, high coating amount, etc., to achieve uniform distribution, reduce alkali content, improve The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a three-dimensional positive material of a carbon quantum point modified, the molecular formula of the ternary positive electrode material is Lini 0.85 CO 0.05 Mn 0.1 O 2 The surface is distributed with carbon quantum dots; wherein the mass fraction of carbon quantum dots is 1%.

[0041] Preparation according to the following method:

[0042] (1) The citric acid is dissolved in water, and it is allowed to 100 mL to obtain a carbon precursor, and then the three-dimensional positive electrode material is added thereto, and the mixed slurry is mixed by the high speed mixture;

[0043] (2) Under the air atmosphere, the mixed slurry obtained by the microwave to the step (1) is treated with a mixed slurry of step (1), and the power of the microwave is 1500W, and the treatment is completed to obtain the tri-element material of the carbon quantum dot.

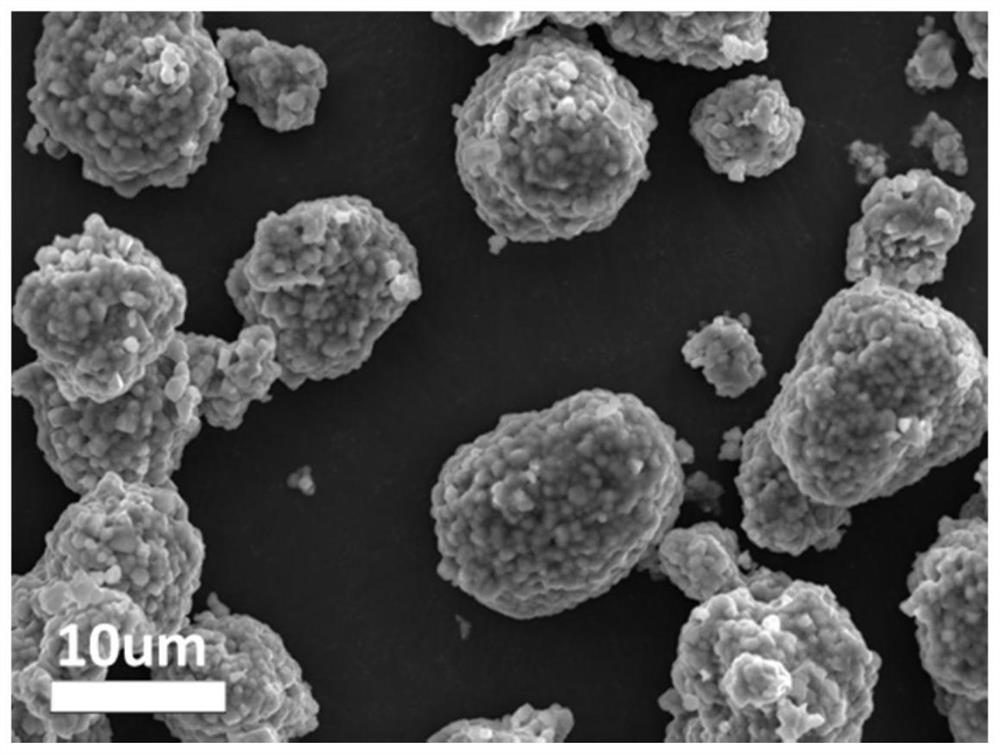

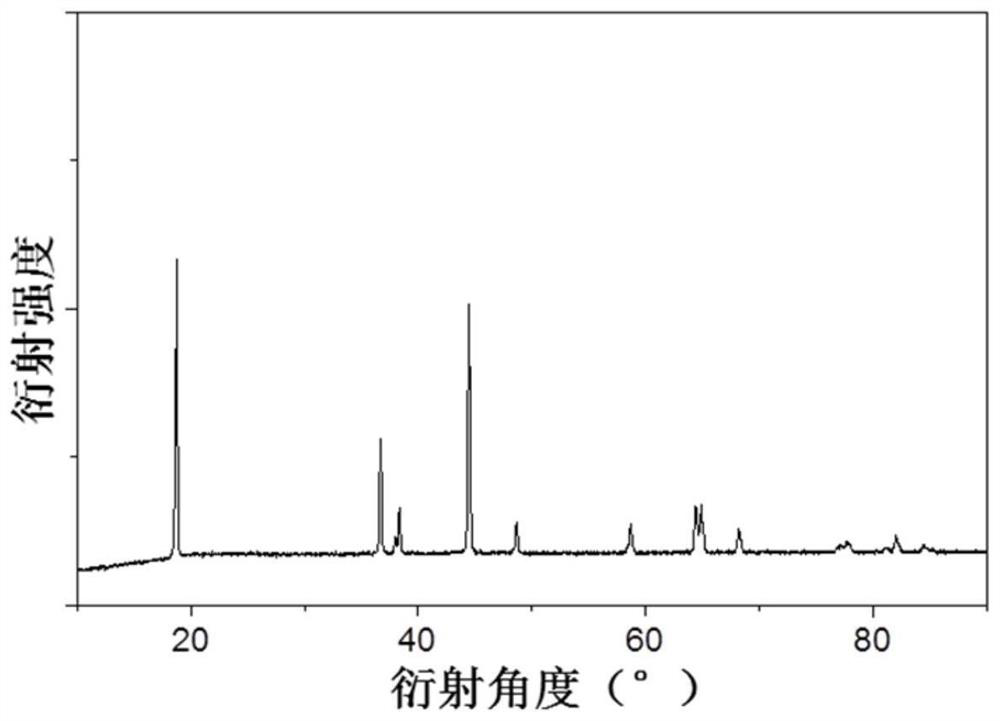

[0044] SEM and XRD testing of the three-dimensional positive material modified to the obtained carbon qua...

Embodiment 2

[0047] This embodiment provides a three-dimensional positive material of a carbon quantum point modified, the molecular formula of the ternary positive electrode material is Lini 0.5 CO 0.3 Mn 0.2 O 2 The surface is distributed with carbon quantum dots; wherein the mass fraction of carbon quantum dots is 0.5%.

[0048] Preparation according to the following method:

[0049] (1) dissolve the citric acid into the water, set to 100 mL, to obtain a carbon precursor, and then add a three-dimensional positive electrode material, and mix the mixed slurry by mixing the high-speed mixing machine.

[0050] (2) Under the air atmosphere, the mixed slurry obtained by the microwave to process the mixed slurry obtained by the step (1), the power of 500W of the microwave is 500 W, and the treatment is completed to obtain the tri-element positive material of the carbon quantum dot.

[0051] After detection, the resulting material of the resulting material 10c / 1c ratio of 0.90, 0.2c charge and di...

Embodiment 3

[0053] This embodiment provides a three-dimensional positive material of a carbon quantum point modified, the molecular formula of the ternary positive electrode material is Lini 0.6 CO 0.2 Mn 0.2 O 2 The surface is distributed with carbon quantum dots; wherein the mass fraction of carbon quantum dots is 0.2%.

[0054] Preparation according to the following method:

[0055] (1) The lactic acid is dissolved into ethanol, allowed to 100 mL to obtain a carbon precursor, and then add a triplet positive material to the mixed slurry by mixing a high-speed mixing machine to obtain a mixed slurry;

[0056] (2) In the oxygen atmosphere, the mixed slurry obtained by the microwave by microwave is treated for 5 min, and the power of the microwave is 3000W, and the treatment is completed to obtain the tri-element positive material of the carbon quantum dot.

[0057] After detection, the resulting material of the resulting material 10C / 1C ratio of 0.88, 0.2c charge and discharge conditions we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com