Fuel cell with separation and transmission of materials and efficient utilization of fuel and operating method thereof

A fuel cell and fuel technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of gas and fuel mixing, difficulty in discharging, and uneven distribution of fuel concentration, so as to improve reaction efficiency, ensure high concentration, and avoid blending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

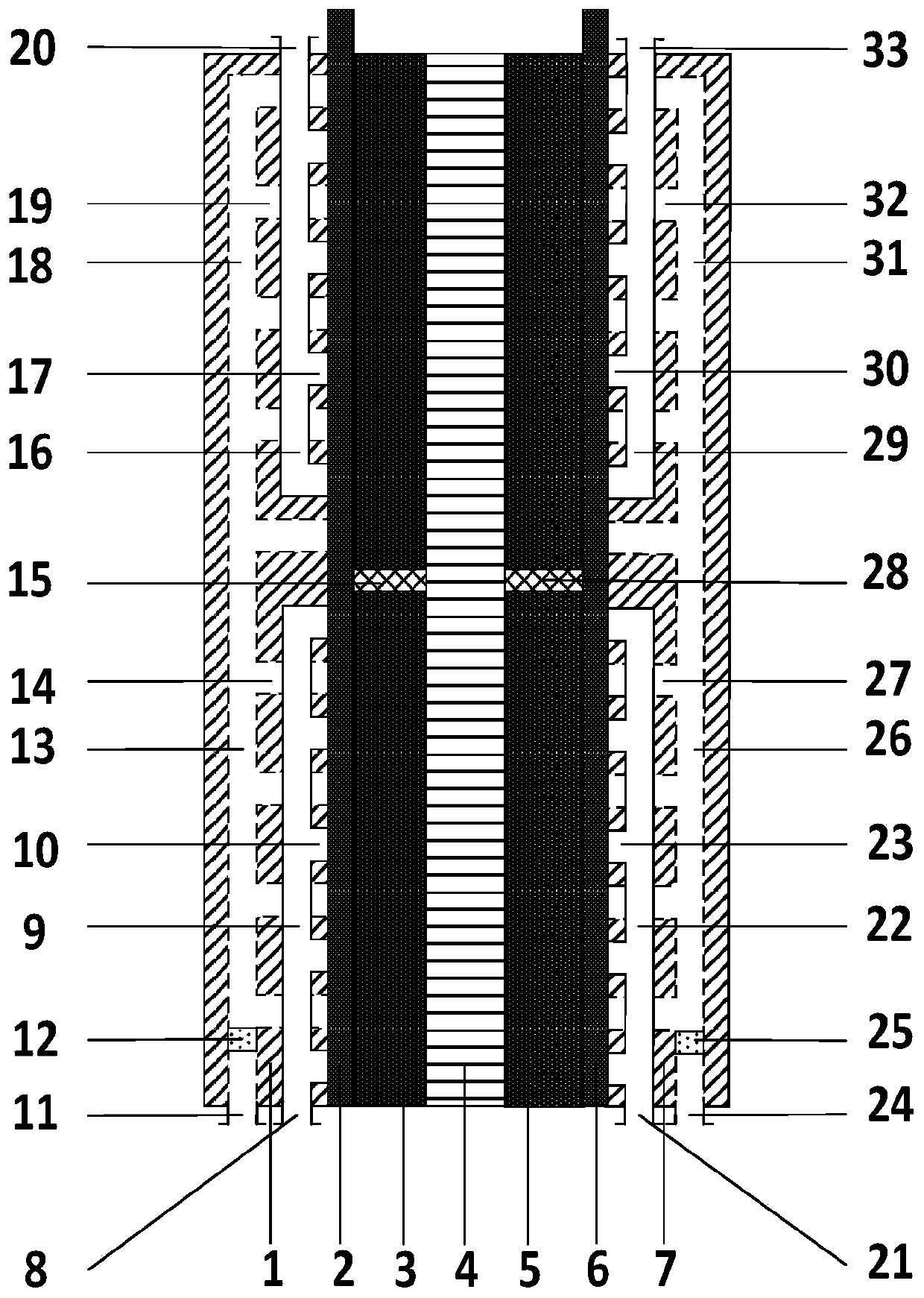

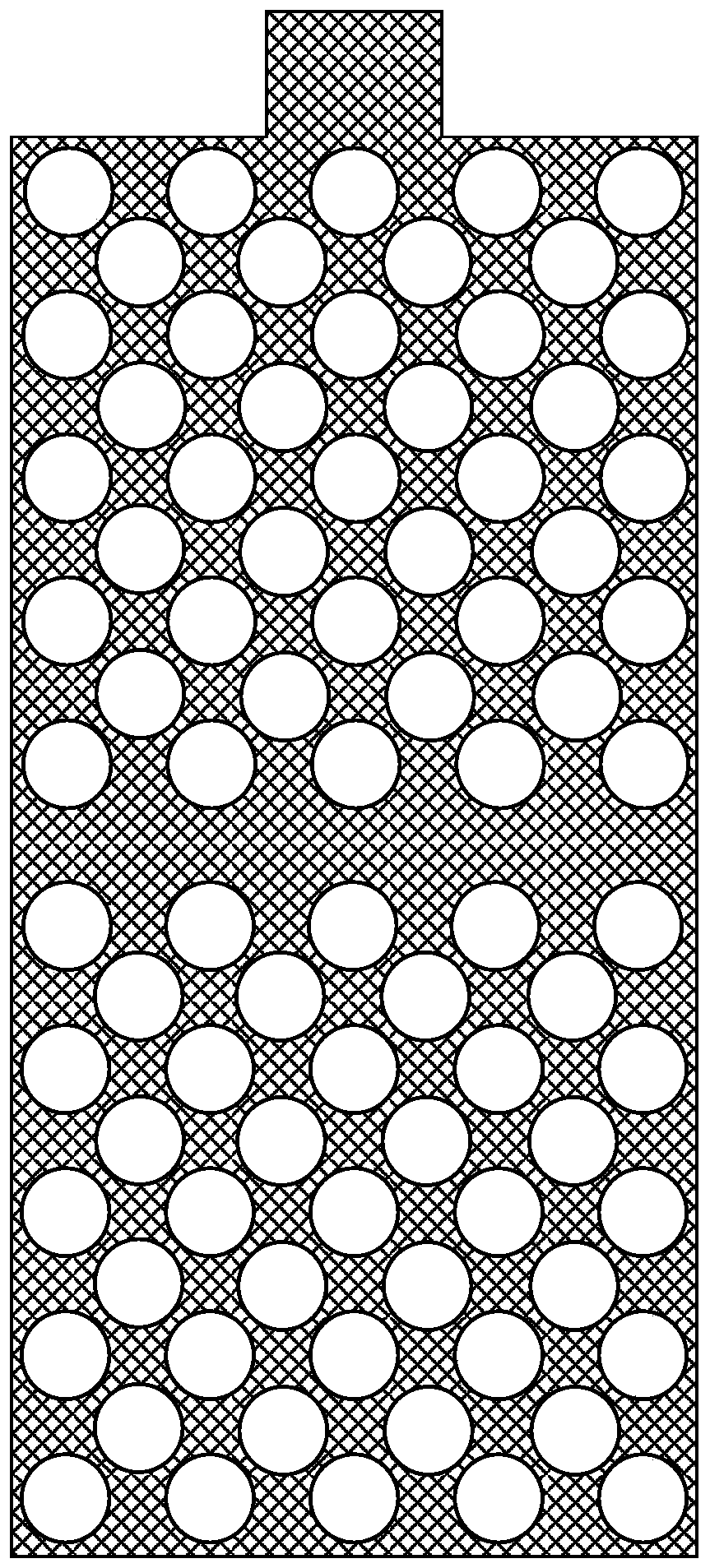

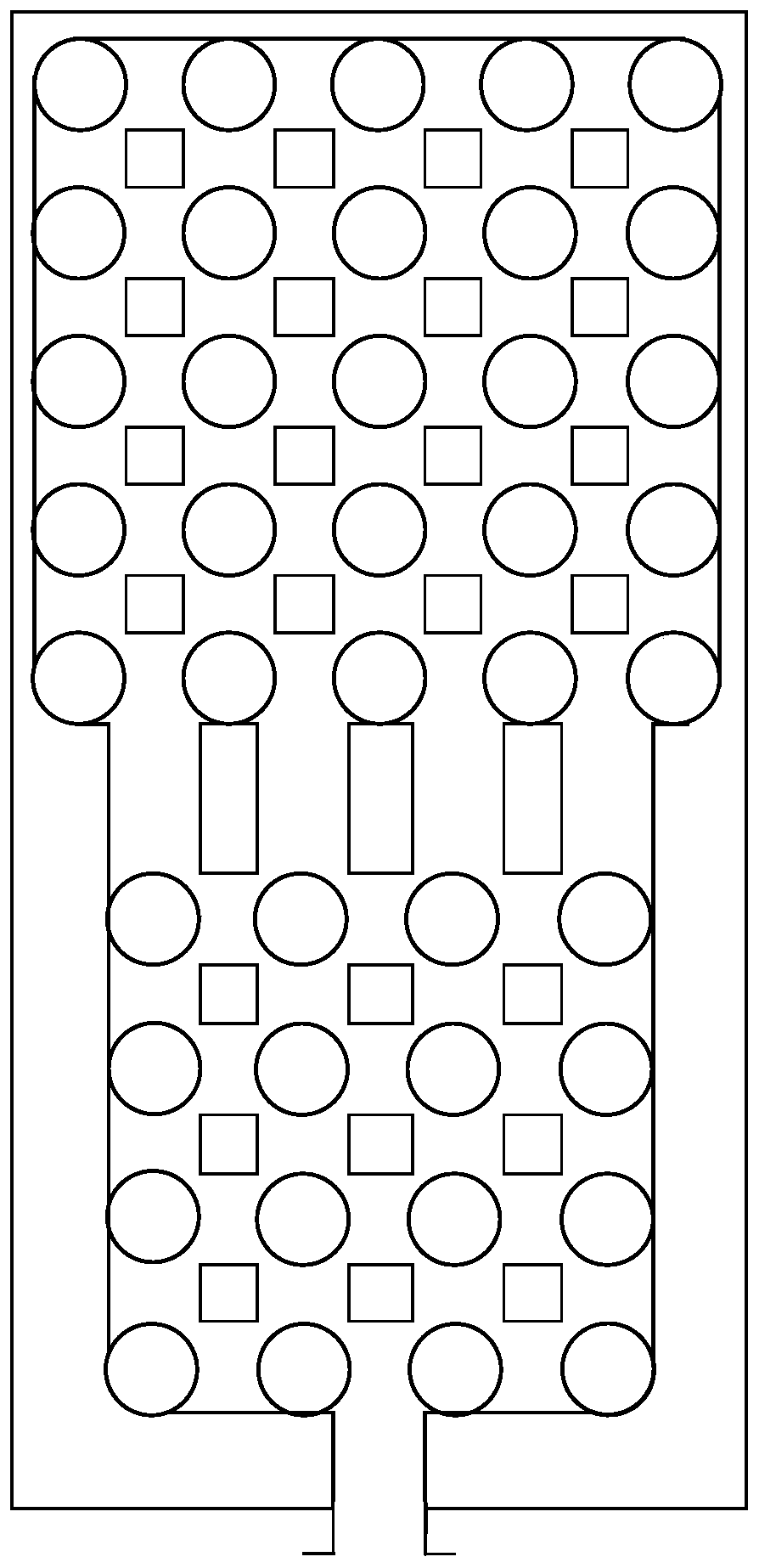

[0044] see Figure 1-2 , the material separation and transport fuel efficient utilization fuel cell of the present invention comprises an anode flow field plate 1, an anode buffer chamber 2, an anode electrode 3, an exchange membrane 4, a cathode electrode 5, a cathode buffer chamber 6 and a cathode arranged on the fuel cell body Flow field plate7.

[0045] The anode flow field plate 1 is independently provided with a borohydride supply pipeline 9, a borohydride product discharge pipeline 13, a hydrogen product discharge pipeline 16 and a hydrogen supply pipeline 18, and the anode flow field plate 1 is provided with There are borohydride inlet 8, borohydride product outlet 11 and hydrogen product outlet 20, one end of borohydride supply pipeline 9, borohydride product discharge pipeli...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap