Electrolyte for lithium titanate battery

A lithium titanate battery and electrolyte technology, which is applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of reducing battery power characteristics, and achieve the effects of enhancing battery specific power, reducing interface impedance, and optimizing composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

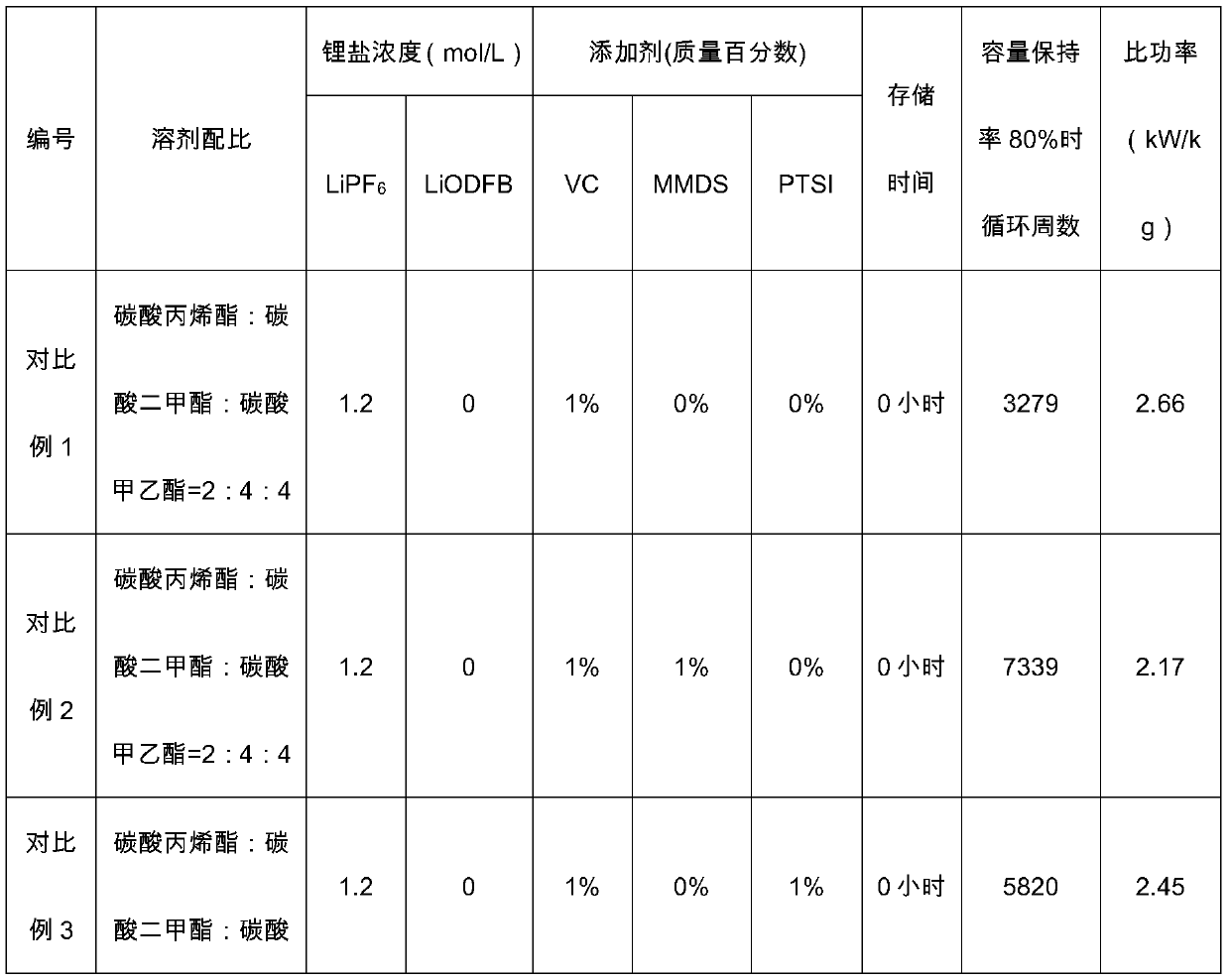

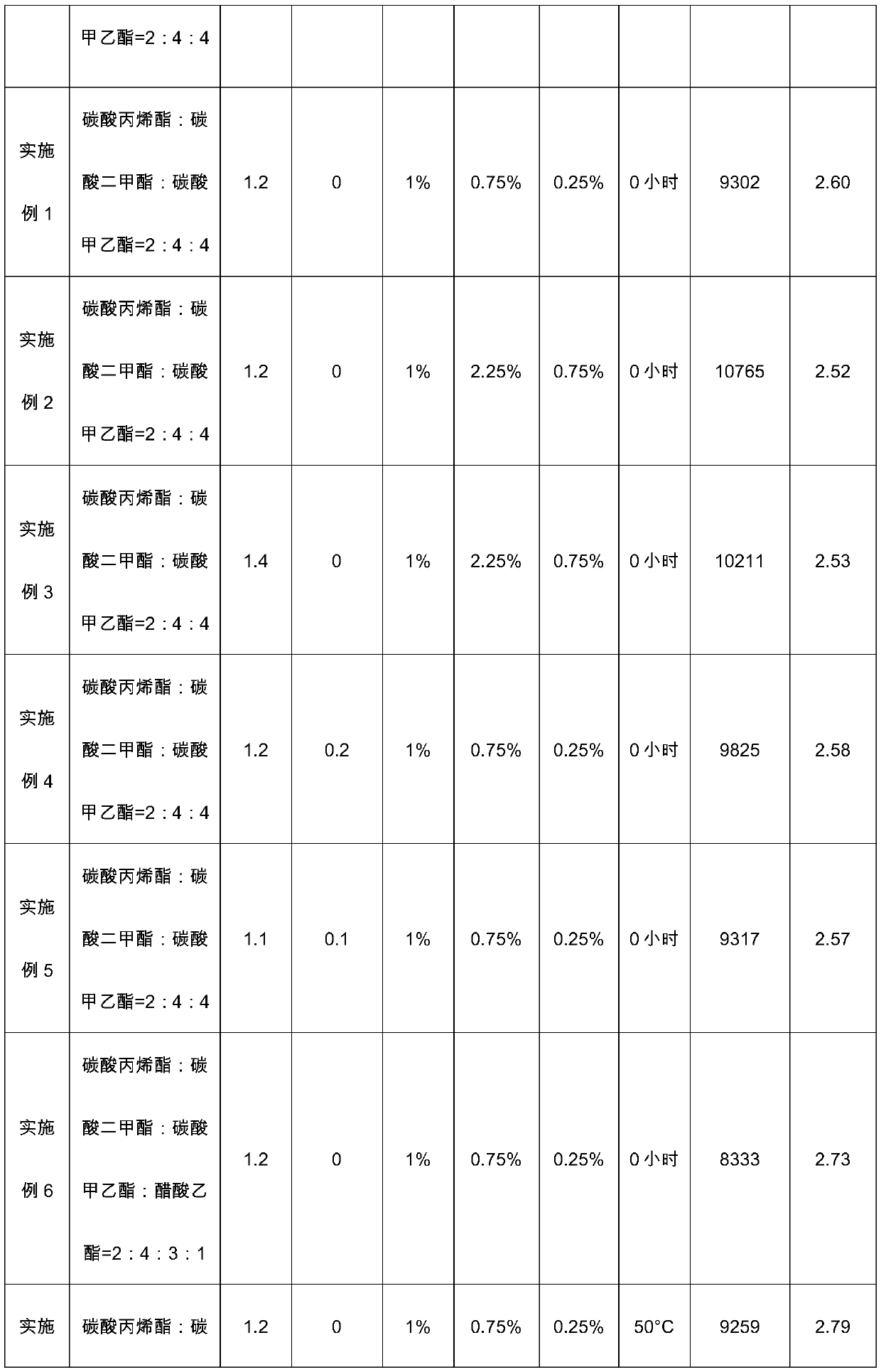

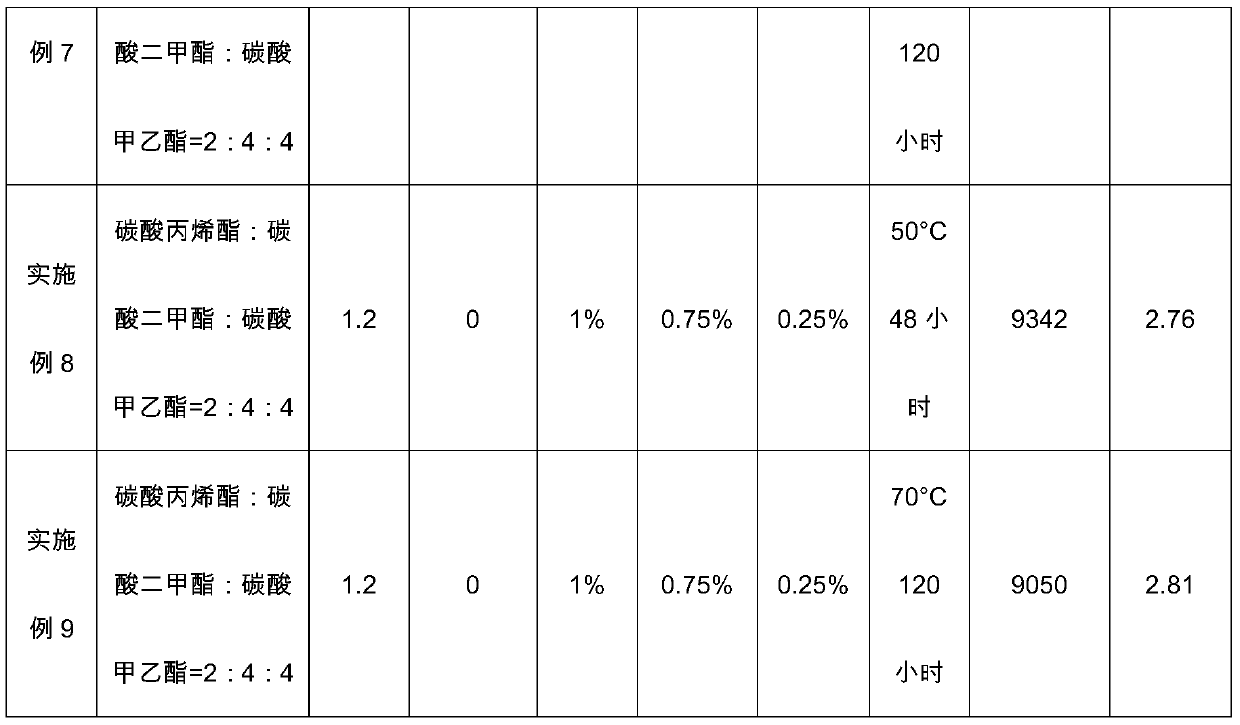

Examples

Embodiment 1

[0032] In a glove box filled with argon, propylene carbonate, dimethyl carbonate and ethyl methyl carbonate were mixed at a mass ratio of 2:4:4, and then 1.2 mol / L lithium hexafluorophosphate (LiPF 6 ), followed by adding 1% by mass of vinylene carbonate (VC), 0.75% by mass of methylene disulfonate (MMDS) and 0.25% by mass of p-toluenesulfonyl Isocyanate (PTSI), after stirring evenly to obtain the required electrolyte, do not store it.

Embodiment 2

[0034] In a glove box filled with argon, propylene carbonate, dimethyl carbonate and ethyl methyl carbonate were mixed at a mass ratio of 2:4:4, and then 1.2 mol / L lithium hexafluorophosphate (LiPF 6 ), then adding mass percentage composition is 1% vinylene carbonate (VC), mass percentage composition is 2.25% methylene disulfonate (MMDS) and mass percentage composition is 0.75% p-toluenesulfonate Acyl isocyanate (PTSI), after stirring evenly, the required electrolyte solution is obtained, and it is not stored.

Embodiment 3

[0036] In a glove box filled with argon, propylene carbonate, dimethyl carbonate and ethyl methyl carbonate were mixed at a mass ratio of 2:4:4, and then 1.4mol / L lithium hexafluorophosphate (LiPF 6 ), then adding mass percentage composition is 1% vinylene carbonate (VC), mass percentage composition is 2.25% methylene disulfonate (MMDS) and mass percentage composition is 0.75% p-toluenesulfonate Acyl isocyanate (PTSI), after stirring evenly, the required electrolyte solution is obtained, and it is not stored.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com