Fermented apple juice rich in active lactobacillus plantarum and preparation method of fermented apple juice

A technology of Lactobacillus plantarum and apple juice, which is applied in the field of fermentation engineering, can solve the problems of probiotic death, lack of probiotic growth factors, and failure to achieve high-activity probiotic fermented juice, and achieve the effect of not being easily inactivated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Specific steps are as follows:

[0064] (1) Add 5‰ of yeast protein, 2‰ of soybean peptone, 0.05‰ of magnesium sulfate, 0.01‰ of manganese sulfate, 5‰ of potassium dihydrogen phosphate, and 20‰ of citric acid into the apple juice. After adding sodium, mix evenly, and heat at 85°C for 15 minutes to sterilize;

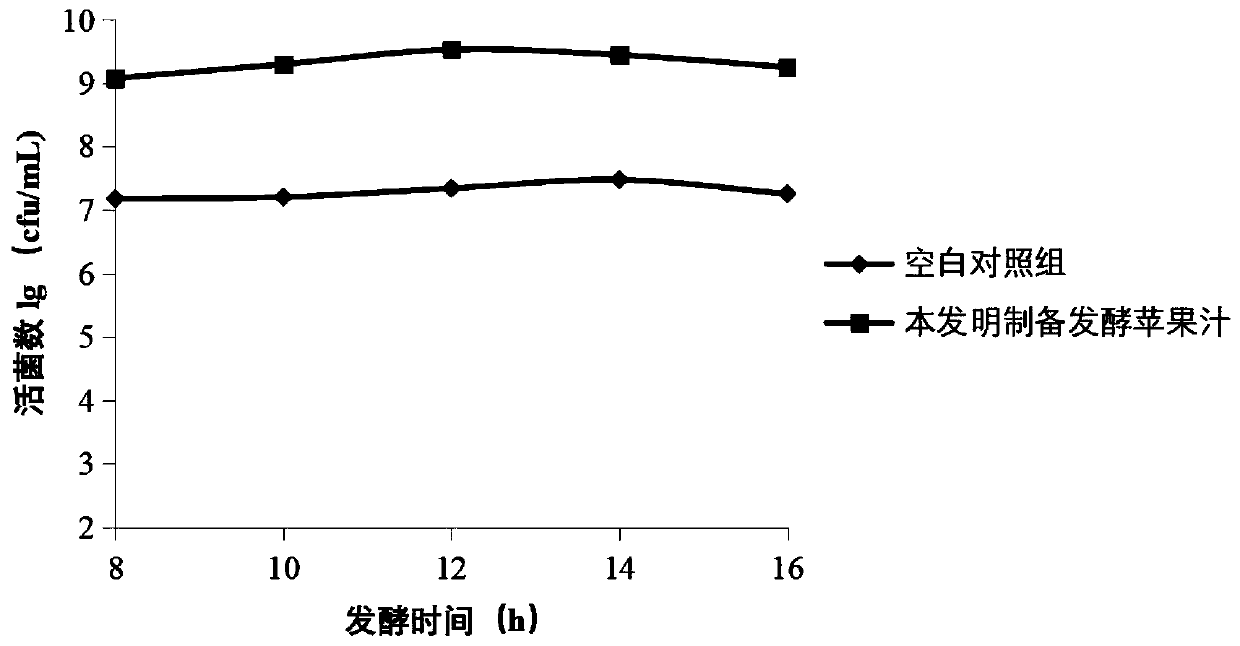

[0065] (2) Cool the sterilized apple juice to below 40°C, and add 1.5×10 7 The amount of cfu / mL was added to Lactobacillus plantarum CGMCC No: 8242 freeze-dried powder, and fermented at a constant temperature at 37°C for 12 hours. At this time, the number of viable bacteria reached 3.4×10 9 cfu / mL (the number of live bacteria can be seen during the fermentation process figure 1 );

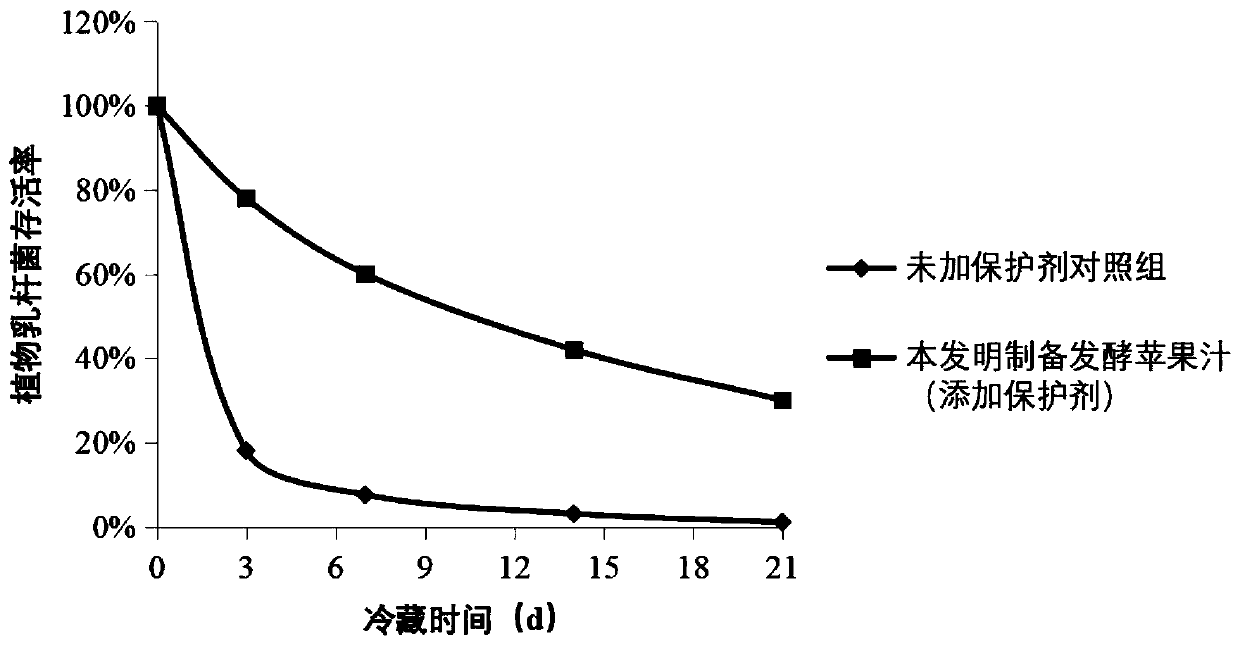

[0066] (3) Add aseptic pectin accounting for 1‰ of the total mass of the fermented juice and 4% whey protein to the fermented fruit juice, place it in a low-temperature refrigerator at 4°C for 21 days after aseptic filling, and take samples for measurement every 3 to 4 days The num...

Embodiment 2

[0069] Specific steps are as follows:

[0070] (1) Add yeast extract accounting for 5‰ of the total mass of apple juice, 0.03‰ of magnesium sulfate, 0.01‰ of manganese sulfate, 7‰ of potassium dihydrogen phosphate, and 15‰ of sodium citrate in the apple juice and mix evenly. Sterilize by heating at 85°C for 15 minutes;

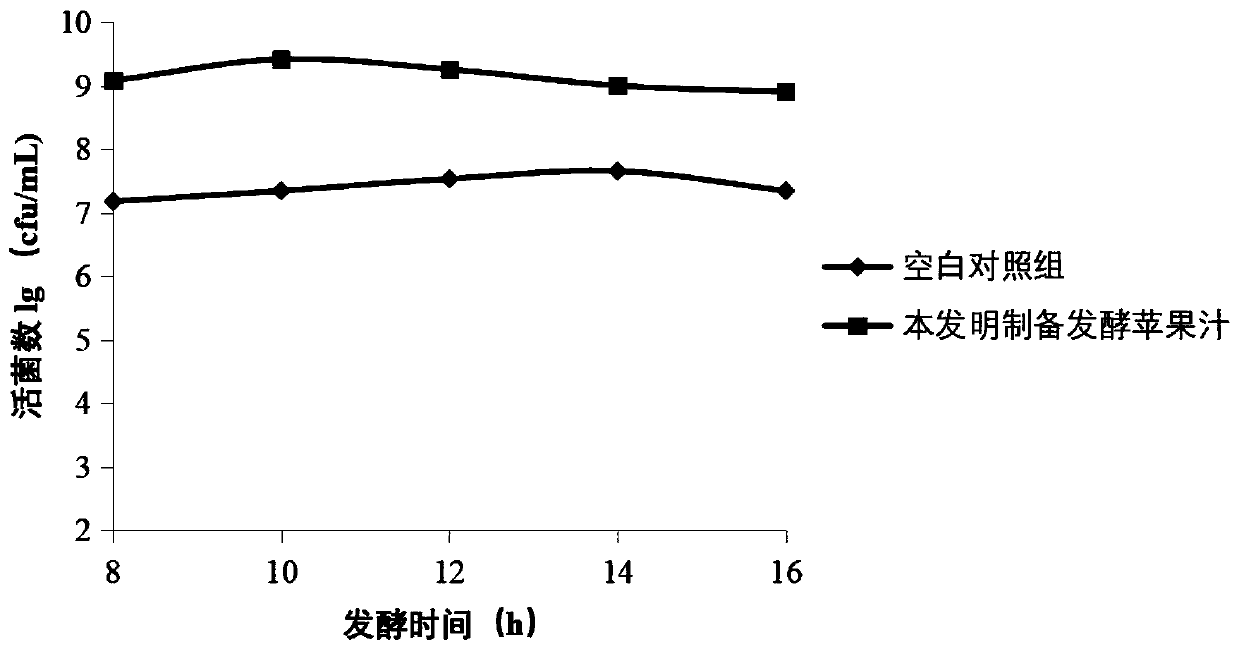

[0071] (2) Cool the sterilized apple juice to below 40°C, and add 1.5×10 7 The amount of cfu / mL was added to the freeze-dried powder of Lactobacillus plantarum CCFM8661 (CGMCC No: 5494), and fermented at a constant temperature at 37°C for 10 hours. At this time, the number of viable bacteria reached 2.6×10 9 cfu / mL (the number of live bacteria can be seen during the fermentation process image 3 );

[0072] (3) Add aseptic pectin, 2% resistant dextrin, and 5% xylooligosaccharides, which account for 1‰ of the total mass of fermented juice, to the fermented fruit juice, and place it in a low-temperature refrigerator at 4°C after aseptic filling On the 21st d...

Embodiment 3

[0075] Specific steps are as follows:

[0076] (1) After adding soybean peptone accounting for 4‰ of the total mass of apple juice, 0.05‰ of magnesium sulfate, 0.01‰ of manganese sulfate, 5‰ of potassium dihydrogen phosphate, and 10‰ of sodium citrate in the apple juice, mix evenly, Sterilize by heating at 85°C for 15 minutes;

[0077] (2) Cool the sterilized apple juice to below 40°C, and add 1.5×10 7 The amount of cfu / mL was added to Lactobacillus plantarum CGMCC No: 5493 freeze-dried powder, and fermented at a constant temperature at 37°C for 10 hours. At this time, the number of viable bacteria reached 3.1×10 9 cfu / mL (the number of live bacteria can be seen during the fermentation process Figure 5 );

[0078] (3) Add aseptic carrageenan and 4% whey protein to the fermented fruit juice, which account for 1‰ of the total mass of the fermented fruit juice. After aseptic filling, place it in a low-temperature refrigerator at 4°C for 21 days, and take samples for measureme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com