A preparation method of an antibacterial stable nanofiltration membrane material

A nanofiltration membrane and stable technology, applied in the field of nanofiltration membranes, can solve the problems such as the inability to store and fix antibacterial components for a long time, poor anti-pollution stability, etc. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

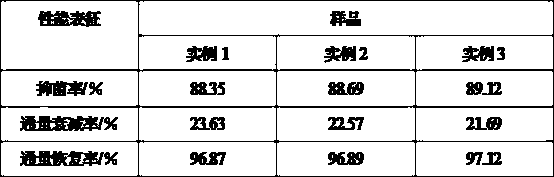

Examples

example 1

[0018] Stir and mix Zanthoxylum bungeanum and deionized water at a mass ratio of 1:5, heat in a water bath at 45°C for 45 minutes, adjust the pH to 3.5 with a 5% acetic acid solution by mass fraction, and obtain a mixed solution with an enzyme dosage of 50 U / g. Add pepsin to the mixture, heat in a water bath at 30°C for 2 hours, continue heating and boiling and keep warm for 105 minutes, centrifuge at 1500r / min for 10 minutes, collect the supernatant and adjust the pH to 7.0 with mass fraction of 5% ammonia water, and use the cut-off Separation and purification of molecular weight 5ku ultrafiltration centrifuge tubes and collection of purified liquid; then weigh 45 parts of purified liquid, 60 parts of pH 7.0 disodium hydrogen phosphate-sodium dihydrogen phosphate buffer, 10 parts of chitosan , 3 parts of dopamine hydrochloride and 1 part of chitinase are placed in a mixer, stirred and mixed and placed under 200W for ultrasonic dispersion for 10 minutes to obtain a coating disp...

example 2

[0020] Stir and mix Zanthoxylum bungeanum protein and deionized water according to the mass ratio of 1:5, heat in a water bath at 47°C for 55 minutes, adjust the pH to 3.5 with a 5% acetic acid solution by mass fraction, and obtain a mixed solution with an enzyme dosage of 50 U / g. Add pepsin to the mixture, heat in a water bath at 32°C for 2 hours, continue heating to boil and keep warm for 12 minutes, centrifuge at 1750r / min for 12 minutes, collect the supernatant and adjust the pH to 7.0 with mass fraction 5% ammonia water, and use cut-off Separation and purification of molecular weight 7ku ultrafiltration centrifuge tubes and collection of purified liquid; then weigh 47 parts of purified liquid, 70 parts of pH 7.0 disodium hydrogen phosphate-sodium dihydrogen phosphate buffer, 12 parts of chitosan , 4 parts of dopamine hydrochloride and 1 part of chitinase are placed in a mixer, stirred and mixed and placed under 250W for ultrasonic dispersion for 12 minutes to obtain a coat...

example 3

[0022] Stir and mix Zanthoxylum bungeanum protein and deionized water according to the mass ratio of 1:5, heat in a water bath at 50°C for 60 minutes, adjust the pH to 3.5 with a 5% acetic acid solution by mass fraction, and obtain a mixed solution with an enzyme dosage of 50 U / g. Add pepsin to the mixture, heat in a water bath at 35°C for 3 hours, continue to heat and boil and keep warm for 15 minutes, centrifuge at 2000r / min for 15 minutes, collect the supernatant and adjust the pH to 7.0 with mass fraction 5% ammonia water, and use cut-off Molecular weight 10ku ultrafiltration centrifuge tube for separation and purification and collect the purified liquid; then weigh 50 parts of purified liquid, 80 parts of pH 7.0 disodium hydrogen phosphate-sodium dihydrogen phosphate buffer, 15 parts of chitosan , 5 parts of dopamine hydrochloride and 2 parts of chitinase are placed in a mixer, stirred and mixed and placed under 300W for ultrasonic dispersion for 15 minutes to obtain a coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com