Layered double-metal hydroxide, composite membrane, application of composite membrane, and suction filtration device

A layered bimetallic and hydroxide technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, oxygen/ozone/oxide/hydroxide, nickel compound, etc., can solve the energy consumption of thermal activation technology Large, toxic, carcinogenic and other problems, to achieve high application prospects and use value, easy operation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

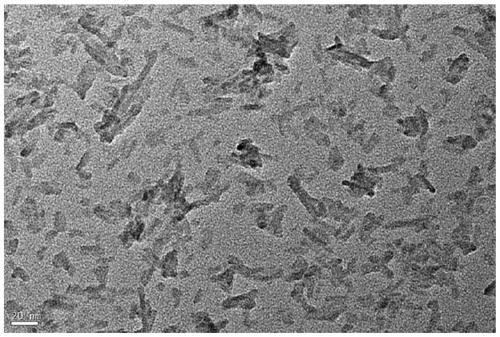

[0046] This embodiment provides a layered double metal hydroxide, which is prepared by the following steps:

[0047] Weigh cobalt nitrate hexahydrate, copper nitrate trihydrate and anhydrous sodium carbonate reagents, place in deionized water, stir and dissolve to obtain a mixed solution. Add sodium hydroxide solution dropwise to the solution to adjust the pH of the solution, then heat the system and keep stirring to complete the reaction and generate a light brown precipitate. After the precipitate was washed, centrifuged and dried, Co-Cu-LDH nanosheets were obtained. Among them, the molar ratio of cobalt nitrate hexahydrate, copper nitrate trihydrate and anhydrous sodium carbonate is 2:1:3, the pH is 9, the heating temperature is 60°C, the heating time is 24 hours, and the drying time is 48 hours.

Embodiment 2

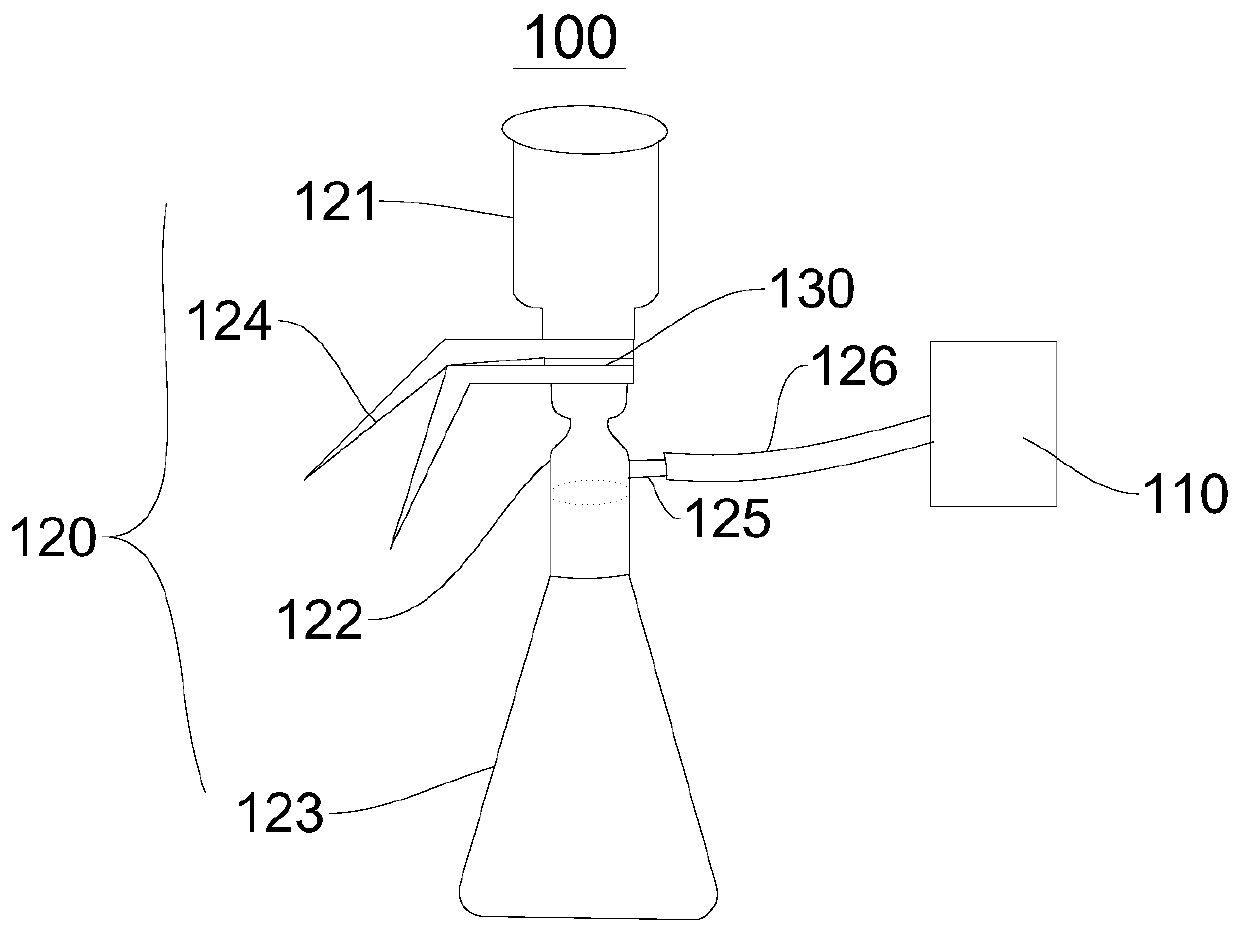

[0049] The present embodiment provides a kind of composite film, and it is prepared through the following steps:

[0050] Place the Co-Cu-LDH nanosheets and nanofibers prepared in Example 1 in a mixed solution of N,N-dimethylformamide (DMF) and polyethylene glycol 200 (PEG200) for ultrasonic dispersion to ensure uniform mixing . Then, the mixed solution is fully stirred, so that the Co-Cu-LDH nanosheets adhere to the surface of the nanofibers; then, in the vacuum filtration device, after laying an organic filter membrane, pour the fully stirred suspension, and vacuum After filtration, the activated PMS composite membrane is obtained. Among them, the mass ratio of Co-Cu-LDH nanosheets to nanofibers is 1:1, the volume ratio of N,N-dimethylformamide (DMF) to PEG200 is 2:1, and the ultrasonic dispersion time is 15 minutes. The stirring time is 15 hours, and the suction filtration condition is -0.1Mpa, 10 minutes.

Embodiment 3-4

[0052] Examples 3-4 provide a layered double metal hydroxide, the preparation method of which is basically the same as the preparation method of the layered double metal hydroxide provided in Example 1, except that the operating conditions are different.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com