Preparation method of high-efficiency environment-friendly seedling culture substrate

A kind of nursery substrate and environmental protection technology, applied in the field of nursery materials, can solve the problems of non-degradable rock wool, environmental secondary pollution, depletion, etc., and achieve the effect of reducing the use of pesticides and chemical fertilizers, promoting germination and seedling growth, and promoting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

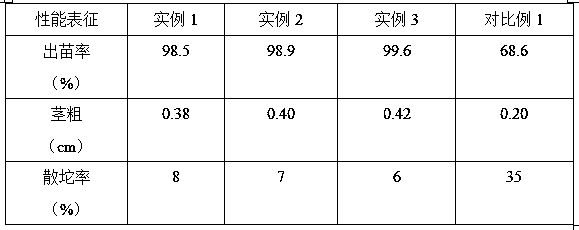

Examples

Embodiment Construction

[0027]Naturally air-dry corn stalks and crush them to 5-10mm to obtain air-dried straws; naturally air-dry fresh cow dung and crush them to 5-10mm to obtain air-dried cow dung. Mix feces and ball mill for 10-20 minutes at a stirring speed of 400-500r / min to obtain the mixture. Put the mixture in a tube furnace and raise the temperature to 200-300°C at a heating rate of 5-10°C / min for 20 minutes. ~30min, then raise the temperature to 700~800℃ at a heating rate of 10~15℃ / min for 60~70min, and cool with the furnace temperature to obtain the green body, crush the green body, and grind it through a 200~230 mesh sieve, that is To obtain the base material, soak the base material in hydrochloric acid with a mass fraction of 5% for 30-50 minutes according to the mass ratio of 1:10, filter the filter residue, wash the filter residue with deionized water until it is neutral, and place the filter residue at a temperature of 60-80°C Dry in an oven to constant weight and cool to room temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com