Method for preparing intraocular lens for preventing after-cataract based on photothermal conversion

A technology of intraocular lens and light-to-heat conversion, which is applied in the direction of medical preparations containing active ingredients, prostheses, pharmaceutical formulas, etc., can solve the problems of limited preventive effect, achieve less side effects, inhibit proliferation and migration, and have good penetration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

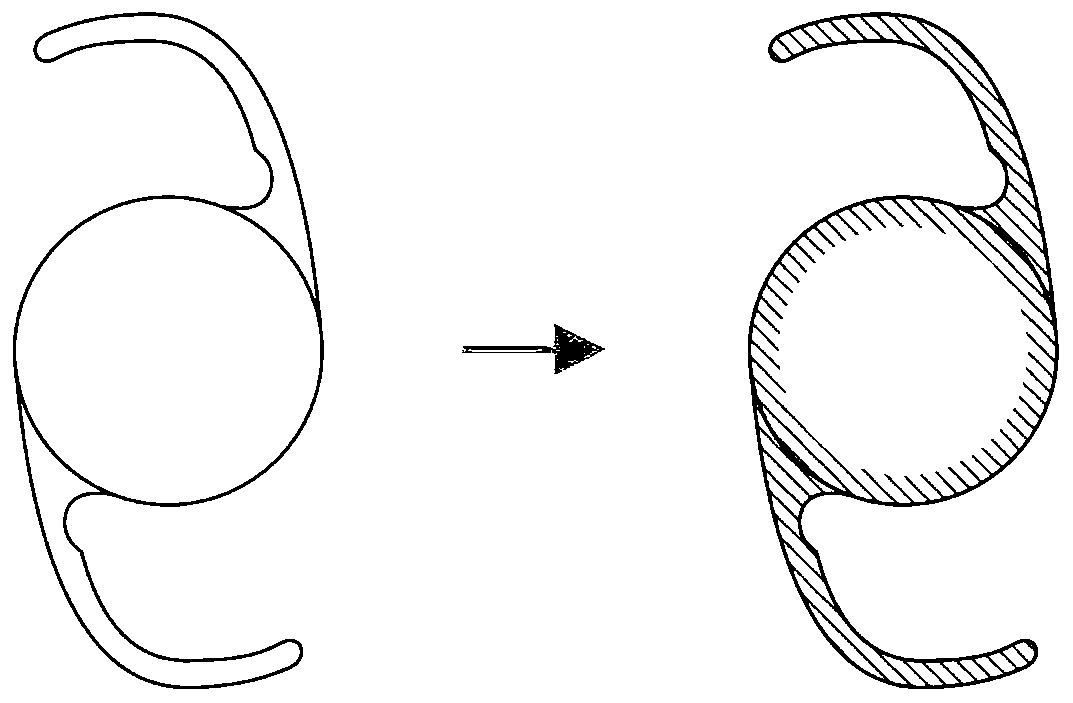

[0036] Add 150 mg of glucose, 200 mg of dopamine hydrochloride and 300 μL of hydrogen peroxide to 100 mL of Tris-HCl buffer solution at pH=8.5 in sequence to prepare a dopamine buffer solution. The intraocular lens (with C-shaped loop) whose optical zone has been covered with a polydimethylsiloxane (PDMS) film was placed in the above-mentioned dopamine buffer solution for reaction, shaken at a constant speed for 30 minutes at room temperature on a constant temperature shaker, and then taken out. Remove the PDMS film on the surface, rinse with ultrapure water for 3 to 5 times, blow dry with nitrogen, and store in the dark.

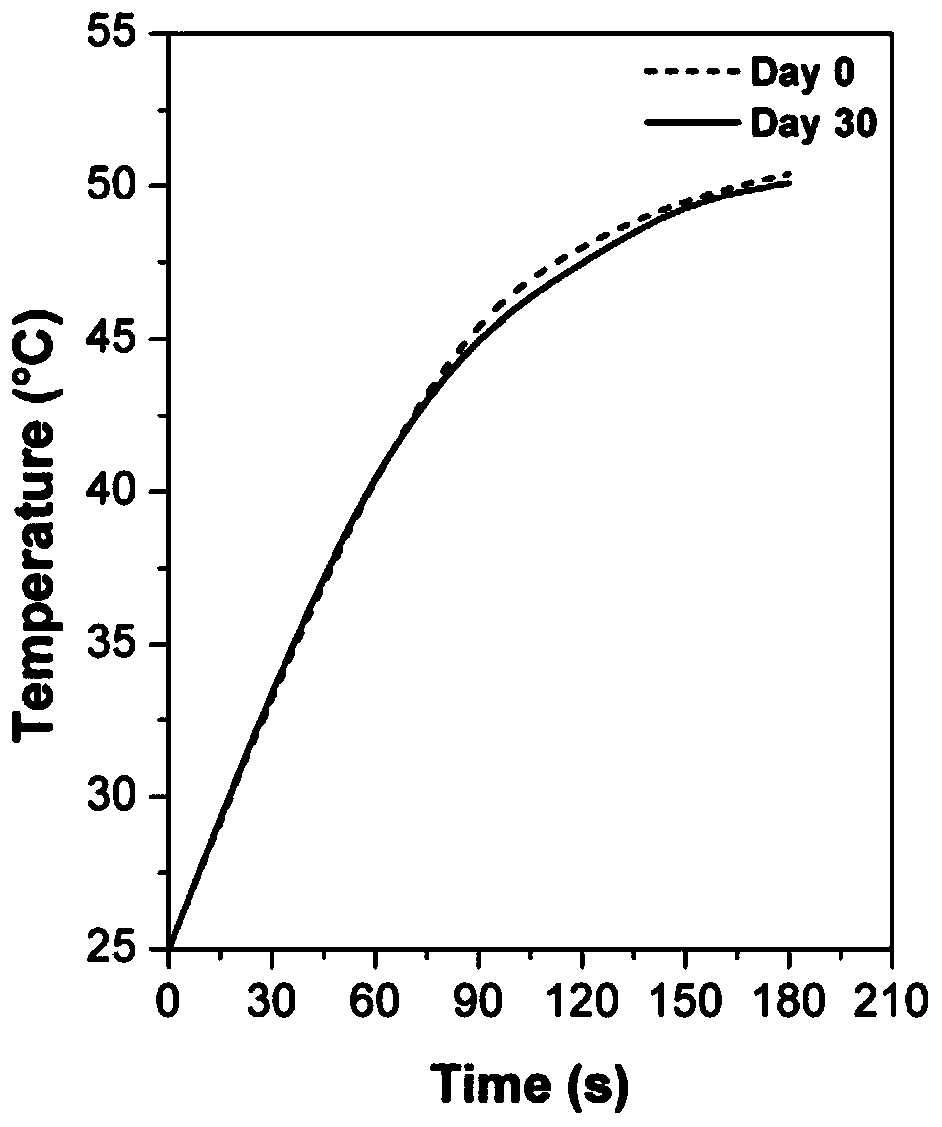

[0037] The intraocular lens with light-to-heat conversion function prepared by this method, such as image 3 As shown, under the irradiation of near-infrared light with a wavelength of 808 nm, the non-optical region can rapidly heat up to about 50 °C within 3 minutes. Turn off the near-infrared light irradiation, and the temperature of the non-optical area...

Embodiment 2

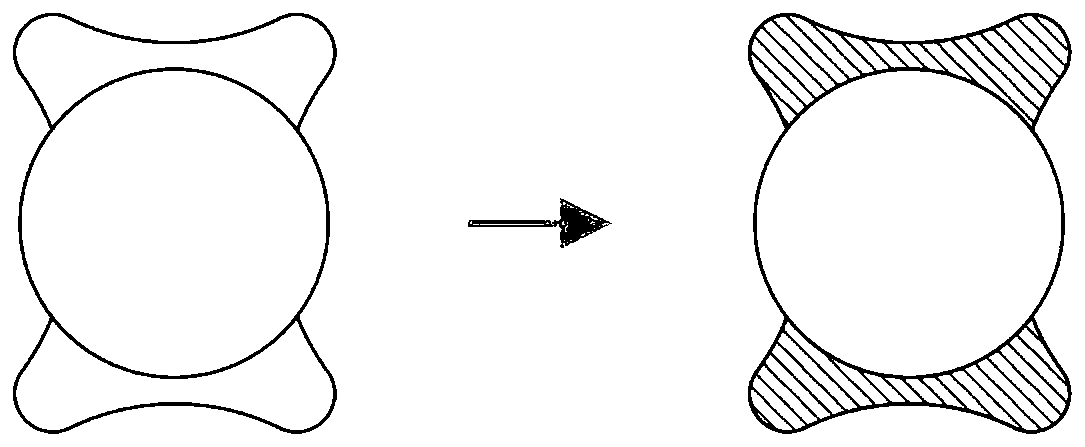

[0039] Add 15 mg of sodium sulfite, 200 mg of dopamine hydrochloride and 20 mg of potassium persulfate to 100 mL of Tris-HCl buffer solution at pH=8.5 in sequence to prepare a dopamine buffer solution. The intraocular lens (with plate-shaped loops) whose optical zone has been covered with a polydimethylsiloxane (PDMS) film was placed in the above-mentioned dopamine buffer solution for reaction, shaken at a constant speed for 10 minutes at room temperature on a constant temperature shaker, and then taken out. Remove the PDMS film on the surface, rinse with ultrapure water for 3 to 5 times, blow dry with nitrogen, and store in the dark.

[0040] The intraocular lens with photothermal conversion function prepared by this method can rapidly raise the temperature of its non-optic region to about 55° C. within 4 minutes under the irradiation of near-infrared light with a wavelength of 808 nm. Turn off the near-infrared light irradiation, and the temperature of the non-optical area o...

Embodiment 3

[0042] Add 125 mg of copper sulfate pentahydrate, 200 mg of dopamine hydrochloride and 200 μL of hydrogen peroxide to 100 mL of Tris-HCl buffer solution at pH=8.5 in sequence to prepare a dopamine buffer solution. Put the intraocular lens (with C-shaped loop) covered with polyimide film in the optical area to react in the above-mentioned dopamine buffer solution, take it out after shaking at a constant speed at room temperature for 20 minutes with a constant temperature shaker, remove the PDMS film on the surface, Rinse with ultrapure water for 3 to 5 times, blow dry with nitrogen, and store in the dark.

[0043] The intraocular lens with photothermal conversion function prepared by this method can rapidly raise the temperature of its non-optic region to about 60° C. within 4 minutes under the irradiation of near-infrared light with a wavelength of 808 nm. Turn off the near-infrared light irradiation, and the temperature of the non-optical area of the intraocular lens graduall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com