Coal-fired boiler smoke sulfur trioxide desorption device

A technology of sulfur trioxide and coal-fired boilers, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, separation methods, etc., to achieve the effect of reducing costs, low cost, and convenient pumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

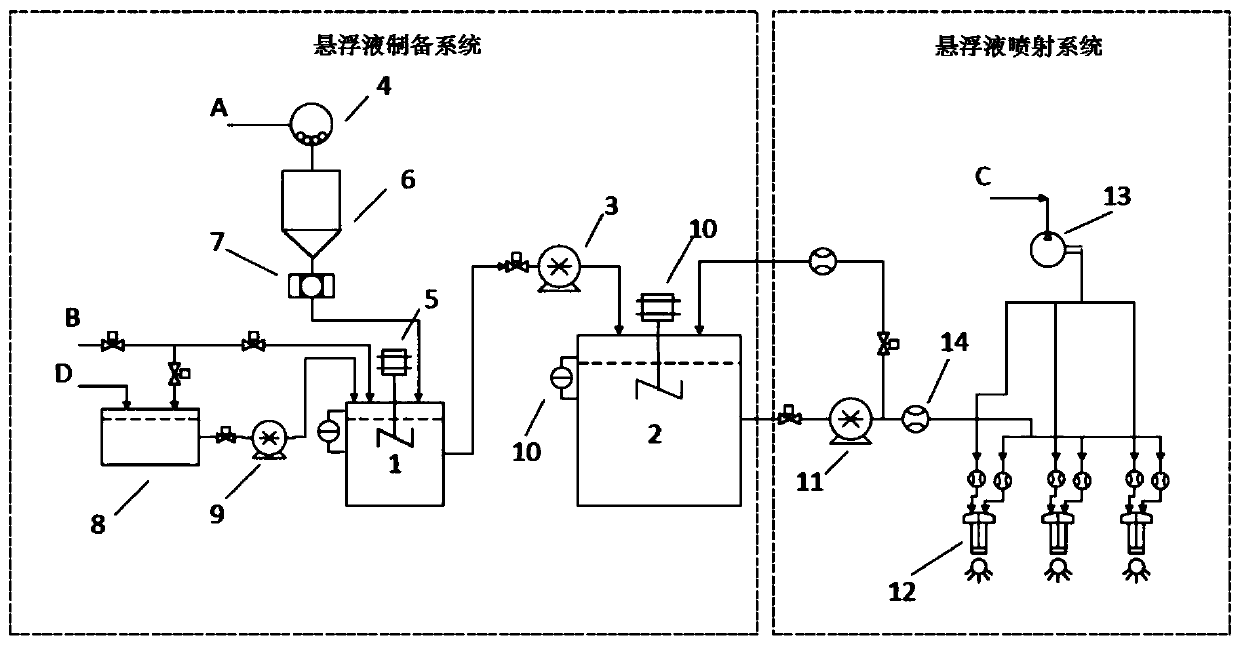

[0026] Such as figure 1 A device for removing sulfur trioxide from flue gas of a coal-fired boiler includes a suspension preparation system and a suspension injection system.

[0027] The suspension preparation system is mainly composed of dispersant preparation tank 8, mill 4, SO 3 It consists of an adsorbent storage tank 6, a feeder 7, a suspension preparation tank 1, and a suspension storage tank 2. Dispersant preparation tank 8 is a configured dispersant solution, and the dispersant is sodium naphthalenesulfonate formaldehyde condensate. SO 3 In the adsorbent storage tank 6 is ground Na 2 CO 3 powder. SO in suspension preparation tank 1 3 Adsorbent A and dispersant solution are provided by feeder 7 and dispersant metering pump 9 respectively, solvent B is demineralized water, and an electric regulating valve is set on the solvent input pipeline to control the input of solvent; SO 3 Adsorbent A, solvent B and dispersant solution are uniformly mixed in the suspension ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com