Method for eliminating phenomena that organic silicon crude monomer hydrolysate is not layered and adhered to equipment

A technology of organosilicon and hydrolyzate, applied in recycling technology, plastic recycling, etc., can solve the problem of non-stratification of organosilicon crude monomer hydrolyzate, and achieve the effects of reducing production costs, high safety factor, and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

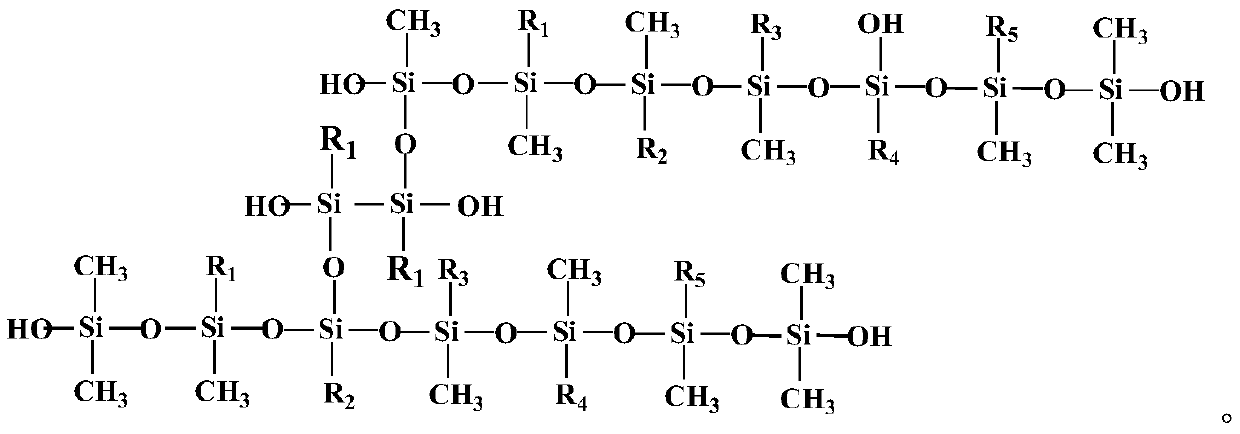

Image

Examples

Embodiment 1-9

[0031] Add a certain amount of potassium hydroxide to the crude monomer hydrolyzate of dimethyldichlorosilane (adhesive state where water and oil are not layered), stir for 30 minutes, then add 90wt% toluene, heat up, and reflux at 130°C Take water for 2 hours, remove part of the water, and then let it stand to observe the stratification of the hydrolyzate and the adhesion of the equipment.

[0032] The potassium hydroxide consumption of embodiment 1-9, hydrolyzate delamination situation and adhesion equipment situation are as shown in table 1:

[0033] The potassium hydroxide consumption of table 1 embodiment 1-9, hydrolyzate delamination situation and adhesion equipment situation

[0034]

[0035] Under the same reflux time, such as 2h, the amount of alkali has an important influence on the non-stratification of water and oil. It can be seen from Table 1 that when the amount of potassium hydroxide is less than 5%, the breakage of the silicon-oxygen-silicon bond cannot be...

Embodiment 10-18

[0037] Add 15wt% potassium hydroxide to the crude monomer hydrolyzate of methylethyldichlorosilane (adhesive state in which water and oil do not delaminate), stir for 30 minutes, then add a certain amount of toluene, heat up, at 130°C Reflux with water for 2 hours, remove part of the water, and then let it stand to observe the stratification of the hydrolyzate and the adhesion of the equipment.

[0038] The toluene consumption of embodiment 10-18, hydrolyzate delamination situation and adhesion equipment situation are as shown in table 2:

[0039] The toluene consumption of table 2 embodiment 10-18, hydrolyzate delamination situation and adhesion equipment situation

[0040]

[0041] Under the same reflux time condition, such as 2h, when the amount of toluene is not the same, there is a significant difference in the layering speed. As can be seen from Table 2, when the amount of toluene is lower than 40%, the phenomenon of non-stratification of water and oil still exists o...

Embodiment 19

[0043] Add 10wt% sodium hydroxide to the crude monomer hydrolyzate of methylpropyldichlorosilane (a liquid state in which water and oil are not separated), stir for 20 minutes, then add 70wt% toluene, heat up, and reflux at 135°C Carry water, remove part of the water, and after standing still, the water and oil two-phase layer will separate; take the oil layer and carry out vacuum distillation under the conditions of 70 ° C and -0.098 MPa to remove toluene to obtain transparent silicone oil, which can be reused after recovery of toluene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com