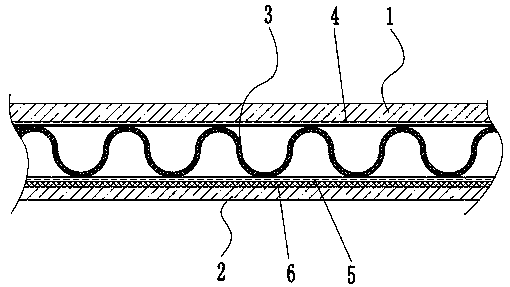

Corrugated paper glue water as well as preparation method and application thereof

A corrugated paper and glue technology, applied in the field of glue and corrugated paper, can solve the problems of volatilization into the packaging box or the inside of the packaging box, corrosion, degumming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of corrugated paper glue, it may further comprise the steps:

[0024] (1) Add 75 parts of cornstarch to the mixer for stirring at 35°C. During the stirring process, gradually add 75 parts of pure water to make the starch paste, and then add 2 parts of sodium hydroxide, And continue stirring for 5 minutes to form material A, wherein the starch is pretreated by ultraviolet light irradiation for 20 minutes;

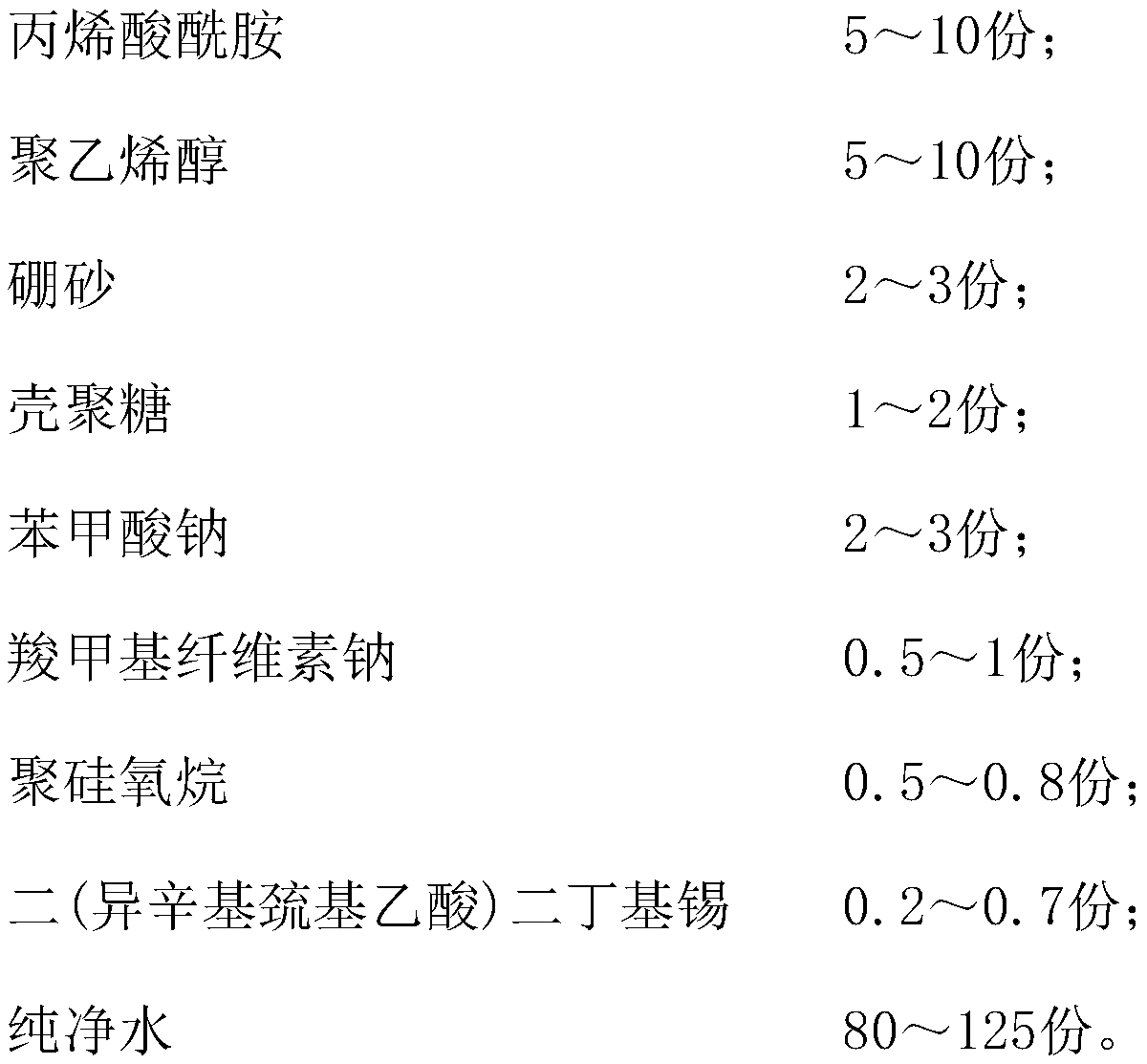

[0025] (2) Mix 7 parts of acrylic acid amide and 7 parts of polyvinyl alcohol uniformly to form material B;

[0026] (3) Add material B to material A, keep stirring during the adding process, then increase the temperature of the stirring environment to 45°C, and then add 2 parts of sodium benzoate, 0.5 parts of sodium carboxymethyl cellulose, and 0.5 parts of poly Siloxane, 0.2 parts of dibutyltin di(isooctyl mercaptoacetate), 2 parts of styrene-butadiene and 15 parts of purified water were continuously stirred for 15 minutes to form material C; ...

Embodiment 2

[0030] A preparation method of corrugated paper glue, it may further comprise the steps:

[0031] (1) Add 80 parts of cornstarch to the mixer at 40°C for stirring. During the stirring process, gradually add 80 parts of pure water to make the starch paste, and then add 3 parts of sodium hydroxide, And continue stirring for 7 minutes to form material A, wherein the starch is pretreated by ultraviolet light irradiation for 25 minutes;

[0032] (2) Mix 5 parts of acrylic acid amide and 5 parts of polyvinyl alcohol uniformly to form material B;

[0033] (3) Add material B to material A, keep stirring during the adding process, then increase the temperature of the stirring environment to 50°C, and then add 2.5 parts of sodium benzoate, 0.7 parts of sodium carboxymethyl cellulose, and 0.6 parts of poly Siloxane, 0.4 parts of dibutyltin di(isooctyl mercaptoacetate), 1 part of styrene-butadiene and 20 parts of purified water were stirred continuously for 18 minutes to form material C;...

Embodiment 3

[0037] A preparation method of corrugated paper glue, it may further comprise the steps:

[0038] (1) Add 85 parts of glutinous rice starch to the mixer for stirring at 45°C. During the stirring process, gradually add 85 parts of pure water to make the starch paste, and then add 5 parts of sodium hydroxide, And continue stirring for 10 minutes to form material A, wherein the starch is also pretreated by ultraviolet light irradiation for 30 minutes;

[0039] (2) Mix 10 parts of acrylic acid amide and 10 parts of polyvinyl alcohol evenly to form material B;

[0040] (3) Add material B to material A, keep stirring during the adding process, then increase the temperature of the stirring environment to 55°C, then add 3 parts of sodium benzoate, 1 part of sodium carboxymethyl cellulose, and 0.8 parts of polystyrene Siloxane, 0.7 parts of dibutyltin bis(isooctylmercaptoacetate), 3 parts of styrene-butadiene and 40 parts of purified water are continuously stirred for 15 to 20 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com